D.C. current sensing device

A sensing device, DC current technology, applied in the direction of measuring device, voltage/current isolation, measuring current/voltage, etc., can solve problems such as complicated circuit debugging, and achieve high cost performance, good stability, and high measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further described now in conjunction with accompanying drawing.

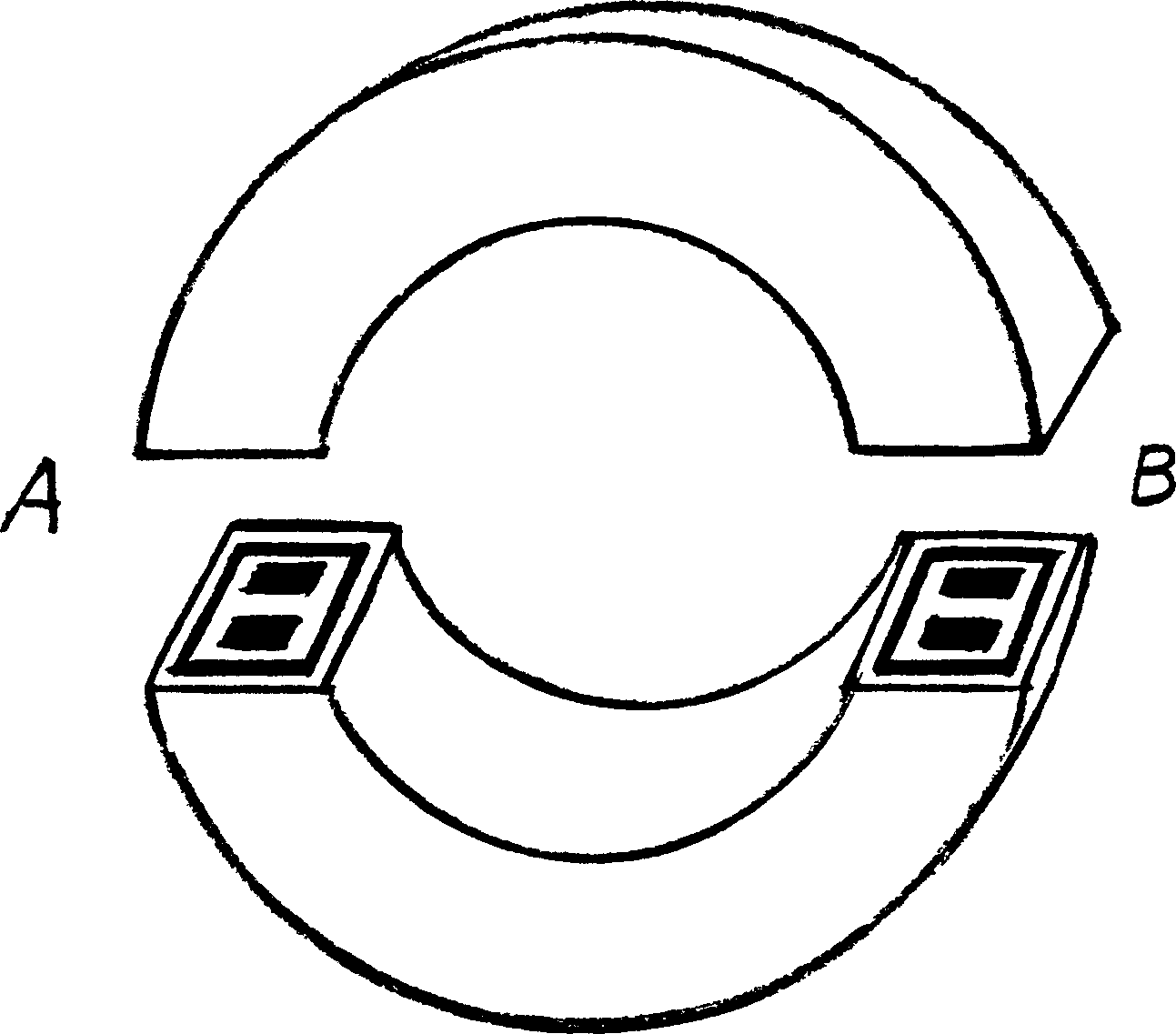

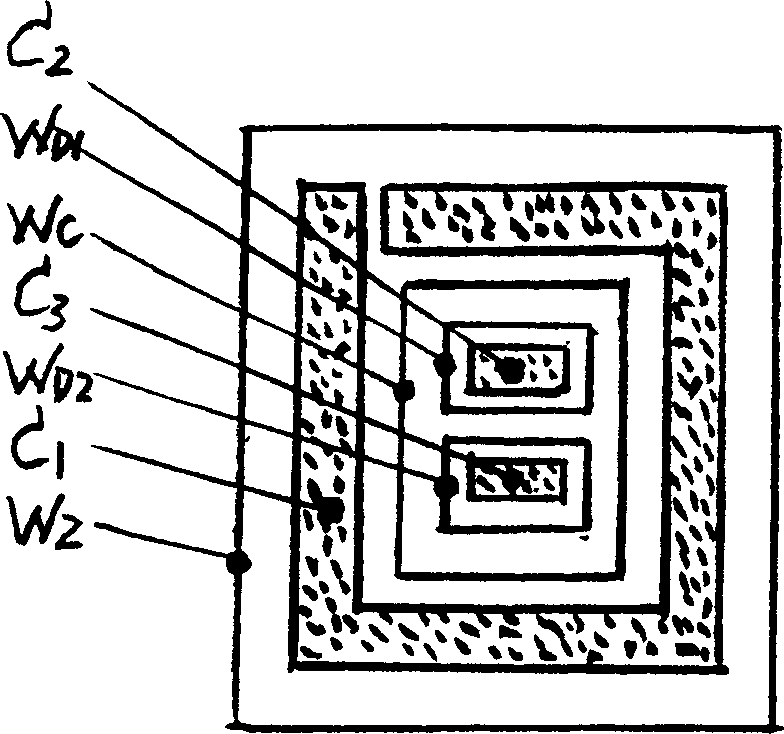

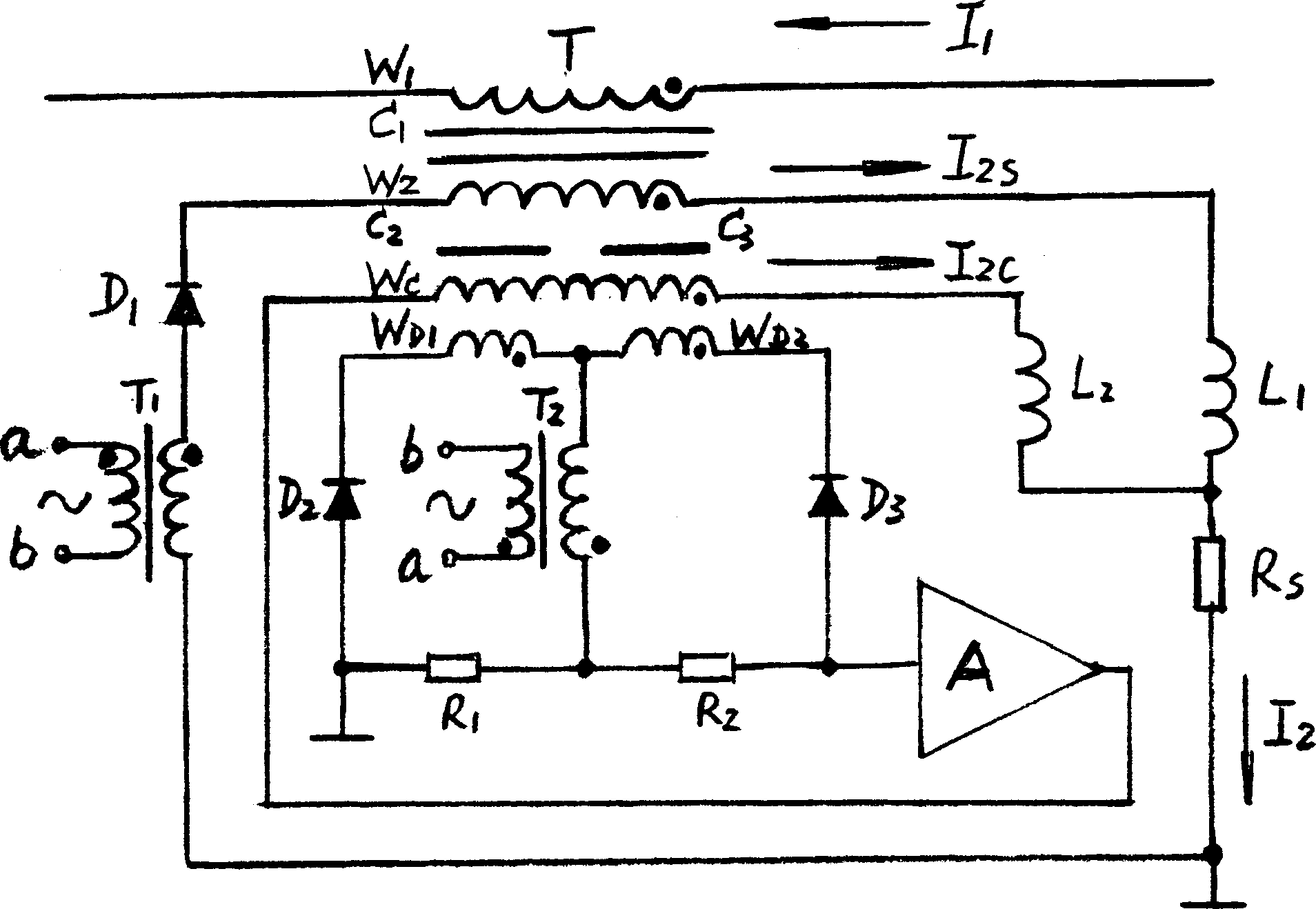

[0017] figure 1 As shown, the shape of the sensor head of the DC current sensor device is a circular ring composed of two half rings, and its cross-section is as follows figure 2 Shown: the first annular detection core C with the same shape 2 and the second annular detection core C 3 The first detection winding W with the same number of turns is respectively wound on D1 , the second detection winding W D2 , after assembling, wind the compensation winding W on the outside of them C , and then place them as a whole in the shielding iron core C with a ring cavity structure 1 in the cavity of the shielded core C 1 Then wind the secondary winding W 2 . image 3 The primary winding W shown 1 That is, the transmission of the measured DC current I 1 bus, from as figure 1 The sensor head shown passes through the center hole.

[0018] image 3 A circuit diagram of the DC curre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com