Glass polishing material without using grinding paste and its using method

A polishing material and slurry technology, applied in grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, polishing compositions, etc., can solve the problems of high polishing cost, reduced quality of abrasive slurry, and easy slurry blockage, etc., to achieve Improve economic benefits, overcome waste of raw materials, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

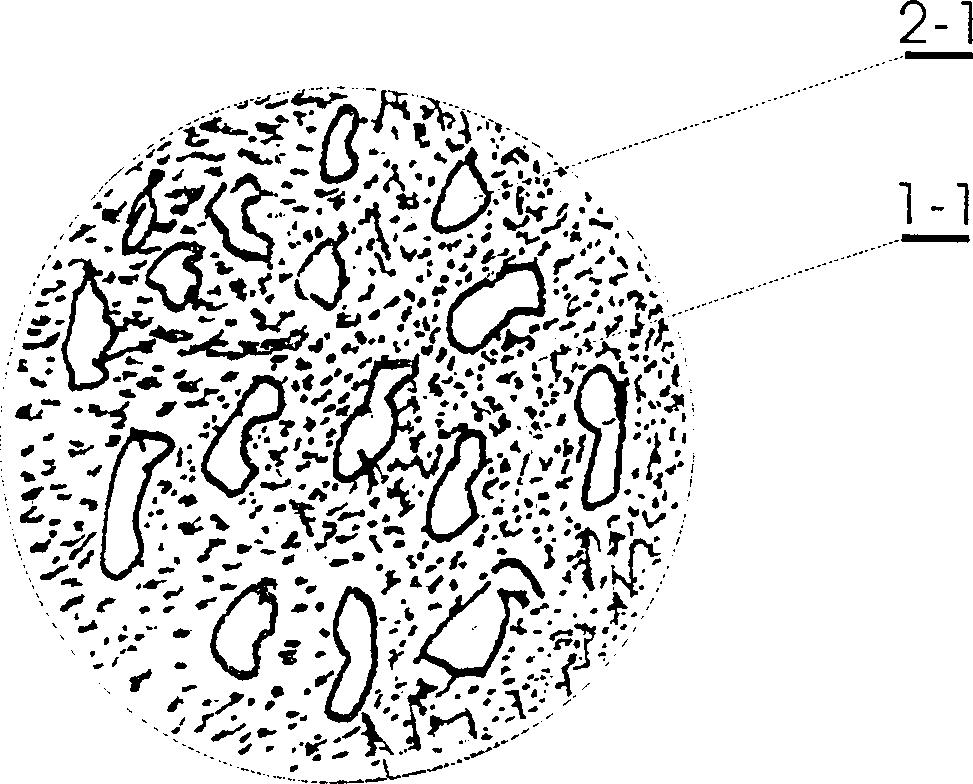

[0019] Get the needle-punched polyester non-woven fabric and polyurethane that are 70%: 30% by weight, and the needle-punched polyester non-woven fabric density is 0.24g / cm 3 ;

[0020] Make the above polyurethane into a solution, add rare earth oxide abrasives rich in 50% cerium oxide, the weight of the cerium oxide is 70% of the total weight of the polishing material, and then impregnate it into the needle-punched polyester non-woven fabric, and then in the aqueous solution Curing and foaming for 30 minutes, and finally removing the solvent in water at 60°C and drying to obtain the finished product.

Embodiment 2

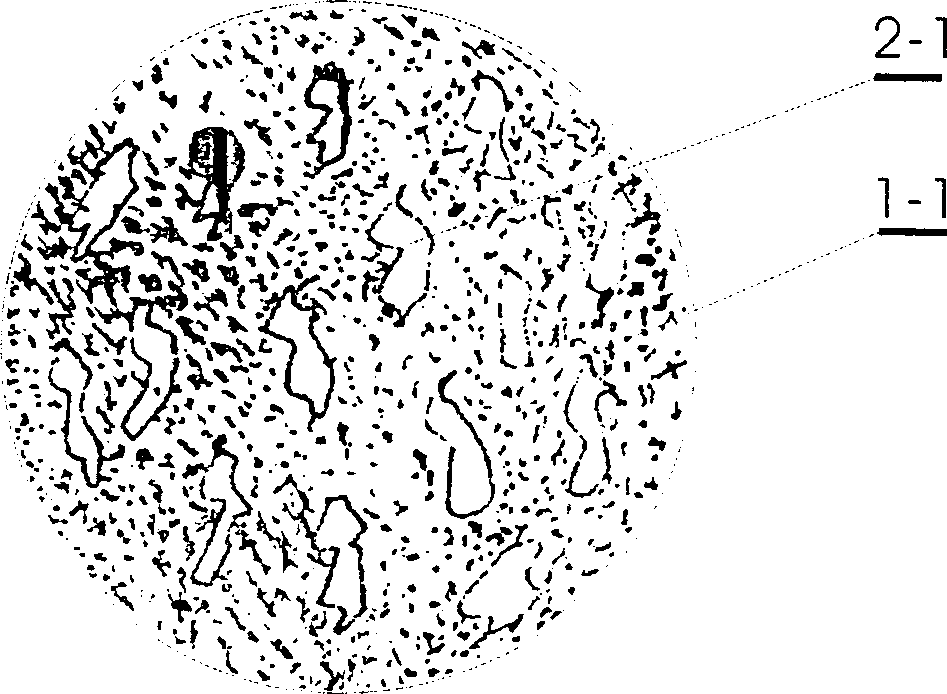

[0022] Get the needle-punched polyester non-woven fabric and polyurethane that are 70%: 30% by weight, and the needle-punched polyester non-woven fabric density is 0.24g / cm 3 ;

[0023] First impregnate rare earth oxide abrasives rich in 50% cerium oxide into the needle-punched polyester non-woven fabric, the weight of the cerium oxide is 45% of the total weight of the polishing material, then after drying, impregnate polyurethane, and then in the aqueous solution Curing and foaming for 30 minutes, and finally removing the solvent in water at 60°C and drying to obtain the finished product.

[0024] Method 1:

[0025] Bond the polishing material prepared in Example 1 above into the NEG workpiece, then soak it in hot water at 50-60°C, absorb enough water, and test the Shore A hardness as 70-85, and then put it on the machine. At the same time, the circulating cooling water is fed to carry out the grinding operation.

[0026] Method 2:

[0027] Install the polishing material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com