U-row continuous extrusion die for metal special-shaped

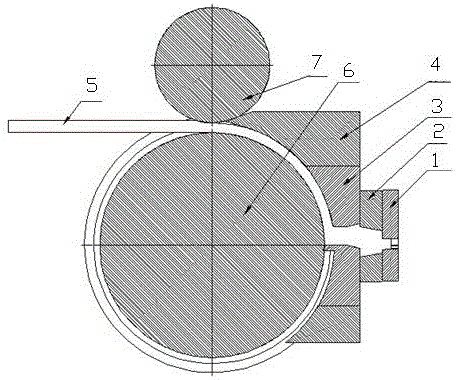

An extrusion die and special-shaped technology, which is applied in the continuous extrusion die of metal special-shaped U-rows, and the field of making conductive heterogeneous U-rows, which can solve the problems of excessive size deviation of the head and tail of the extruded profile, poor forming conditions, mold materials, and high performance requirements. increase and other problems, to achieve uniform and stable metal flow speed, which is beneficial to subsequent processing and saves labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

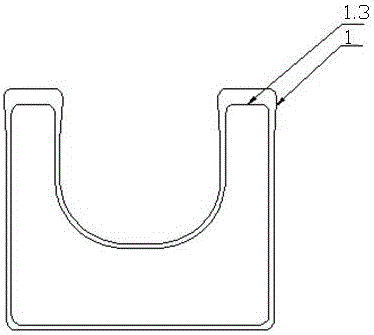

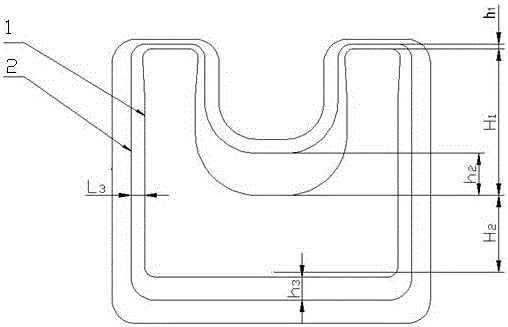

[0047] Such as Figure 9 , Figure 10 As shown, the sizing area of the mold body is 4-8mm long; the angle formed by each side wall of the flow-promoting zone and the axis line of the mold body is 35°, and the length of the flow-promoting zone is L 1 =3mm; the angle formed by each side wall of the transition zone and the axis of the mold is α5°, and the length of the transition zone is L 1 =3mm; the flow-promoting zone and the transition zone, the transition zone and the sizing zone are smoothly connected by an arc; the flow-blocking zone is 9-5, 9-6, and the angle between the flow-stopping zone and the axis line of the mold body is 10°, and the inner U The type adopts no bevel design, that is, the bevel angle is 0°. Such as Figure 8 , Figure 11 , Figure 12 As shown, the outlet section of the gasket is translated by h1=2mm, h2=1.5 mm, h3=4 mm, h4=19.5 mm by each side of the inlet section of the mold body, and the side wall of the gasket flow-promoting area and the axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com