Method for quick resistance trimming by using laser on printed circuit board directly

A printed circuit board and laser resistance trimming technology, which is applied in the fields of printed circuit, printed circuit manufacturing, circuit, etc., can solve the problems of manufacturing troubles, time-consuming and labor-intensive testing errors, and the inability to improve the product quality rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

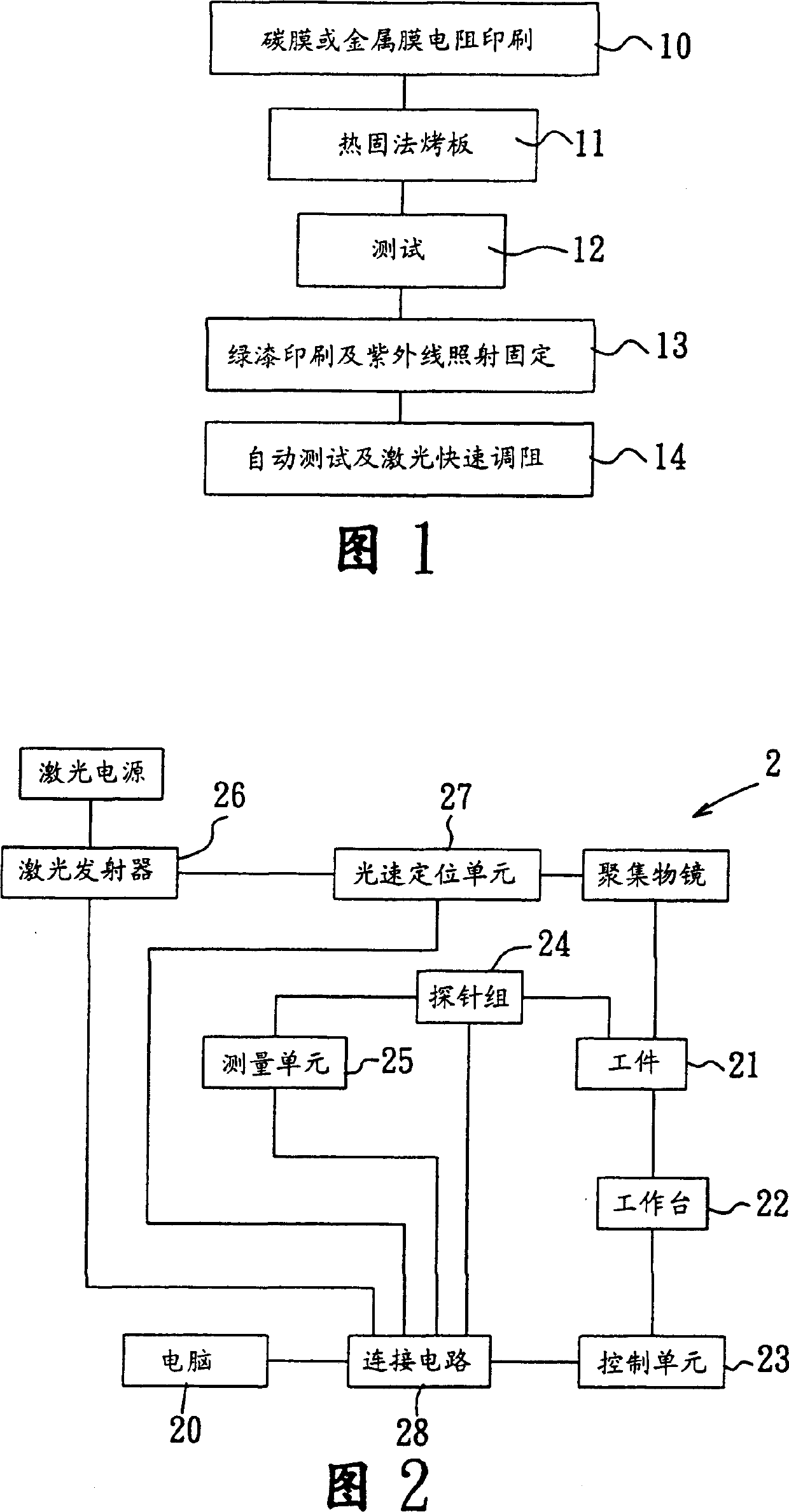

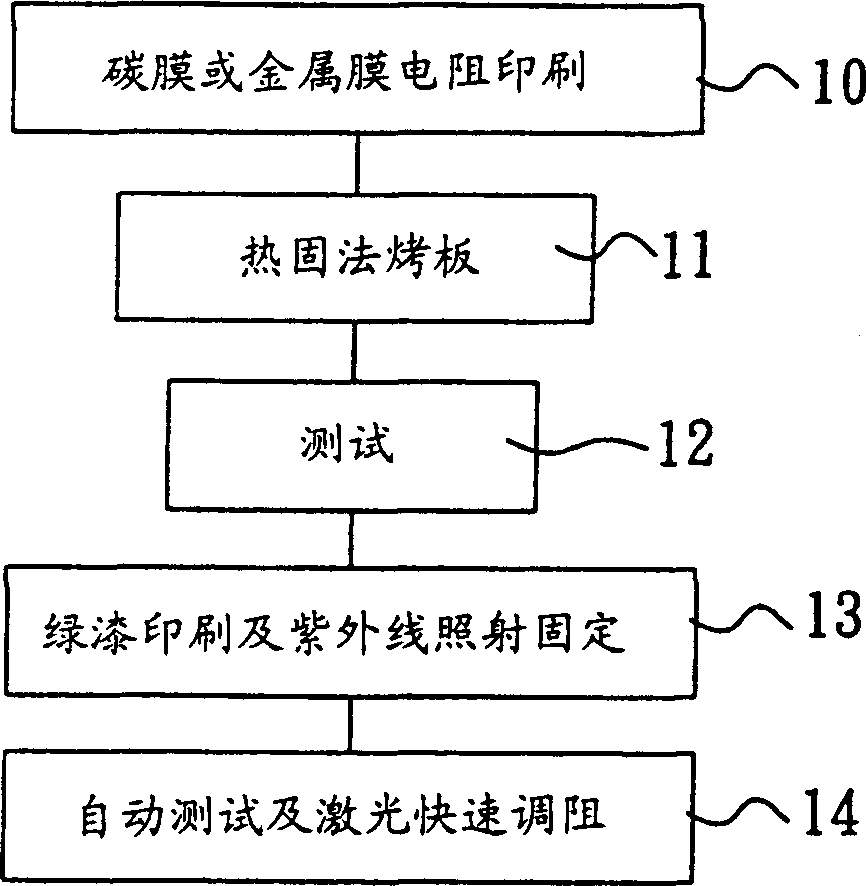

[0016] Referring to FIG. 1 , it shows a preferred embodiment of the method of direct laser trimming on a printed circuit board according to the present invention. Generally, there are two ways to layout (layout) resistors on a printed circuit board, one of which is to directly paste individual (resistance adjusted) chip resistors on the printed circuit board by means of surface mount technology (SMT). . The other is to directly print thick / thin film resistors on the printed circuit board, and then test and adjust the resistance of the resistors, and this printed circuit board with thick / thin film resistors is the adjustment method of this embodiment. The object on which the blocking method is to be implemented. The method of this embodiment includes: a. First, provide a printed circuit board printed with several thick / thin film resistors. As shown in block 10 to block 13 in Figure 1, the process of manufacturing a printed circuit board with several thick / thin film resistors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com