Sealing material with excellent sliding property and wear resistance and for prventing fine powder leakage

A technology of sealing material and fine powder, which can be applied to equipment of electric recording process applying charge pattern, electric recording process applying electric charge pattern, textile and other directions, and can solve the problems of leaking toner, toner leakage, and fine toner leakage. , to achieve the effect of preventing leakage, low wear coefficient and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

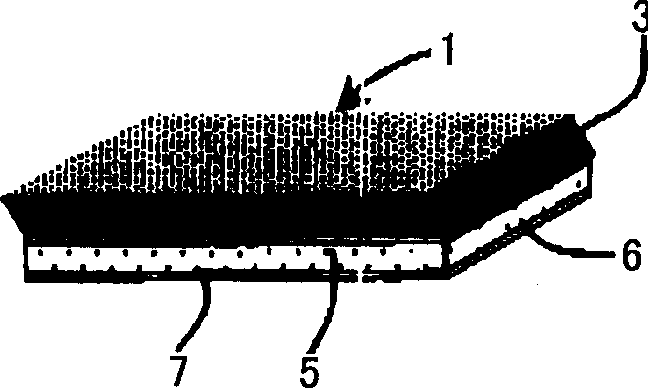

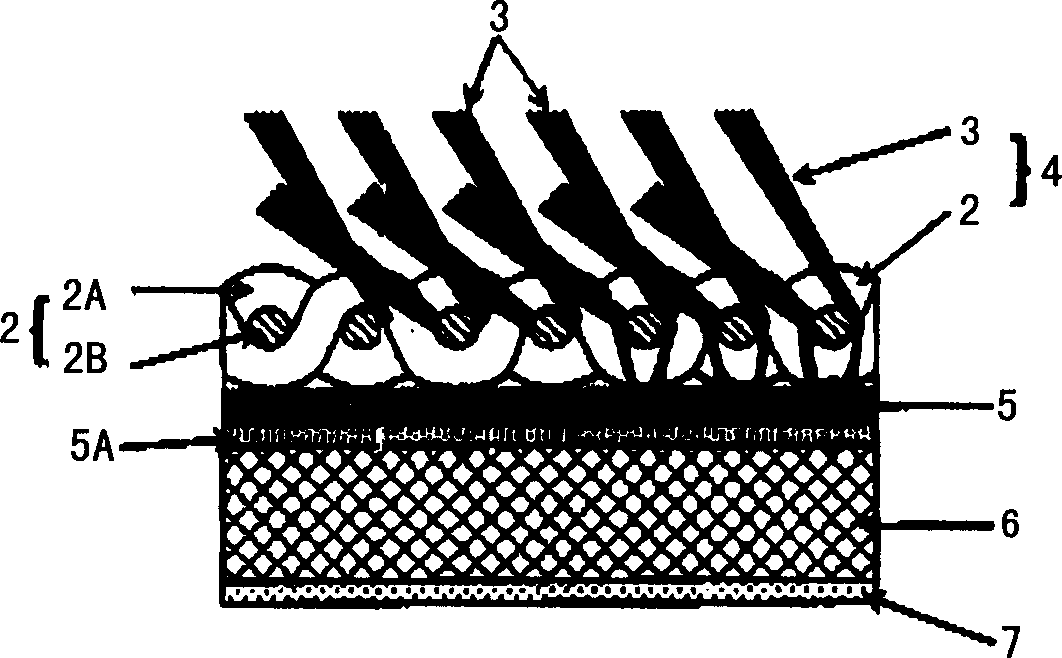

[0023] Embodiment 1 of the present invention will be described below. Furthermore, since the sealing material of this example can obtain an image with high resolution, it is suitable for use in the case of a magnetic roller in a developing chamber of an electrophotographic copier using a fine toner of 10 μm or less. figure 1 shows the three-dimensional state of the sealing material 1, figure 2 An enlarged cross-sectional structure of the sealing material 1 is shown.

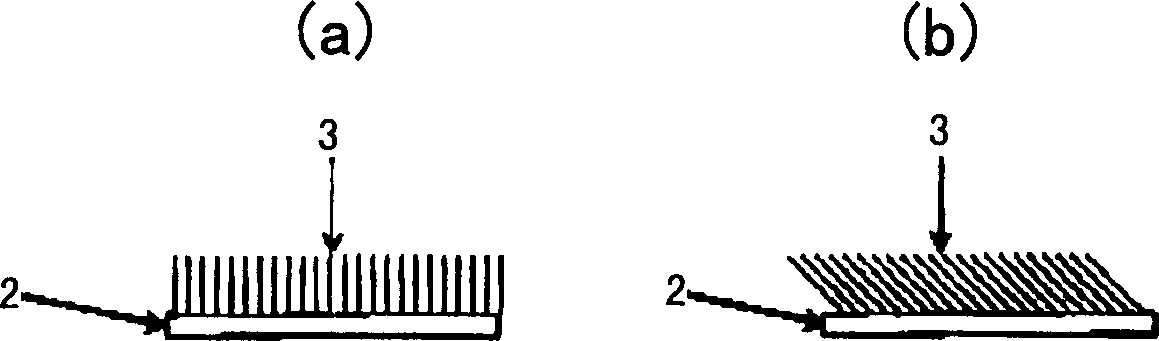

[0024] This sealing material 1 is the structure that is joined by the base fabric 2 that has fluff 3, the coating 5 on the back of base fabric 2, and soft and elastic backing layer 6, is arranged below the backing layer 6 The structure is fixed to the adhesive layer 7 of the applicable part. Such as figure 2 As shown, the base fabric 2 of the plain weave structure has a monofilament fiber degree of 0.1 to 6.0 dTex, a fiber cross-sectional flatness ratio of 1.1 or more, and an average tensile strength of 22 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com