Apparatus and method for treating cooking fume, peculiar small gas and other harmful substance

A technology of harmful substances and odors, applied in chemical instruments and methods, oil fume removal, separation methods, etc., to achieve the effects of low installation and maintenance costs, reduced fan power, and overcoming the problem of oil dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

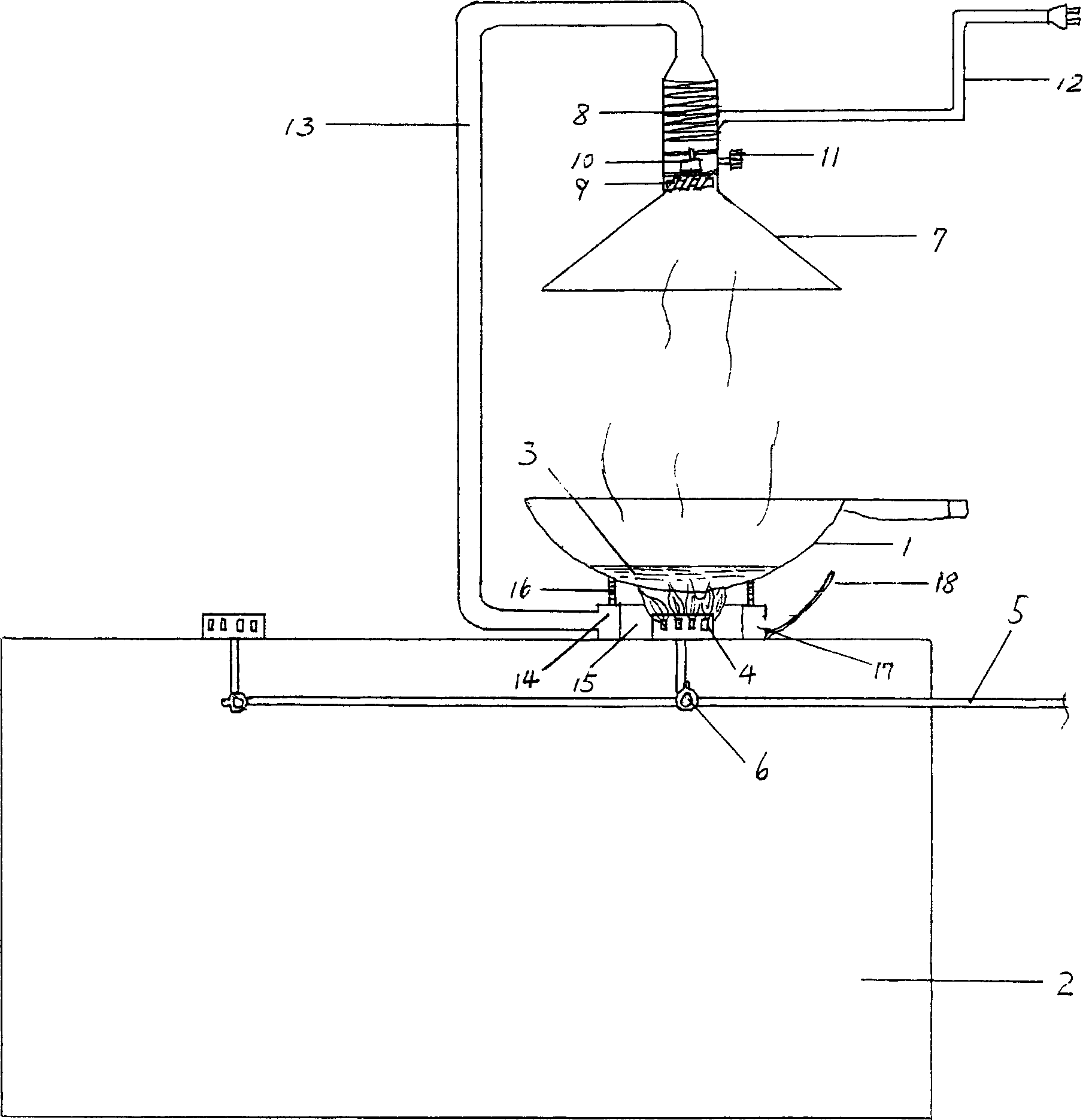

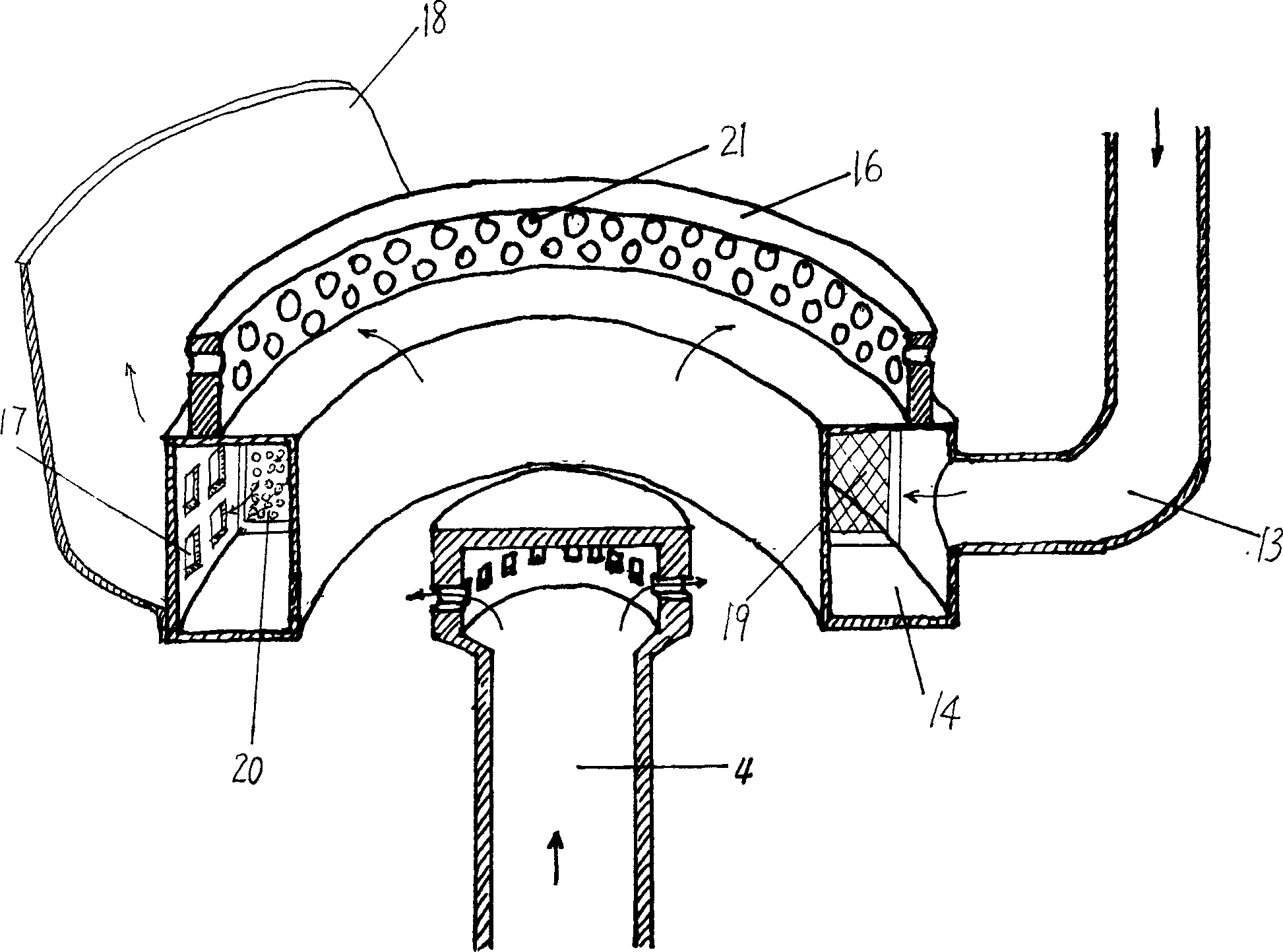

[0031] Example 1: Portable oil fume treatment device such as figure 1 As shown, the cooking pot 1 is placed on the cooking range 2. There is cooking oil in the pot3. The gas enters the burner 4 through the pipeline 5 and the valve 6, and the cooking oil is heated to produce oil fume after burning and heating the cooking pot. Most of the oil fume will be collected by the fume collecting hood 7 of the portable oil fume treatment device. Air, oil fume, odorous gas and some harmful gaseous substances from the combustion of coal gas all enter the telescopic tube 8 under the action of the exhaust fan 9 driven by the exhaust fan 10 to form a special gaseous mixture (the telescopic tube is used to adjust the smoke hood and the distance between cooking utensils). The mixture continues to enter the reaction chamber 14 through the ventilation pipe 13 under the action of the exhaust fan. After being treated, it is discharged from the outlet 17 of the reaction chamber, and is directly ...

Embodiment 2

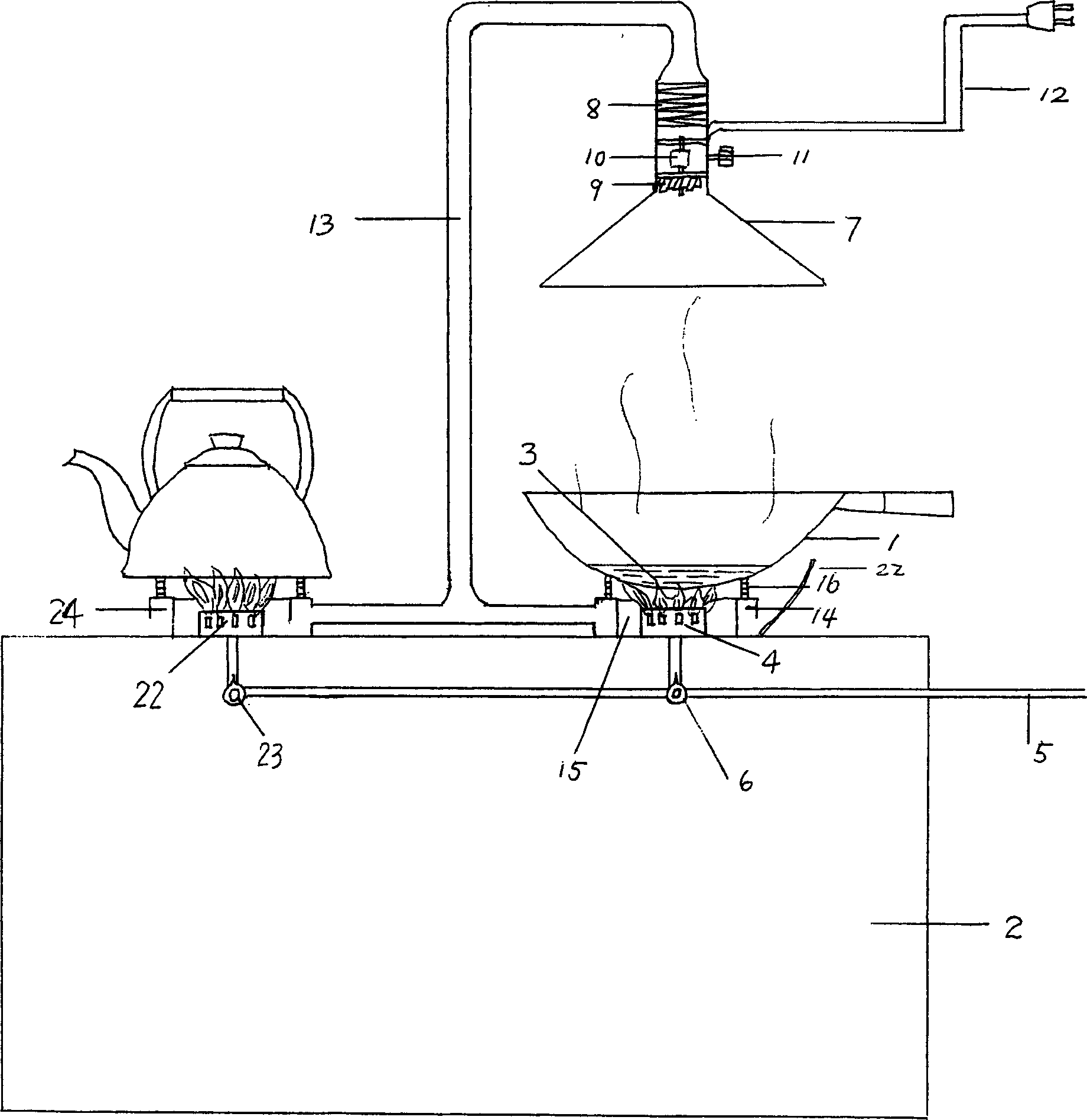

[0033] Embodiment 2: It is another portable oil fume treatment device such as image 3 As shown, this treatment device differs from the previous one only in that the ventilation pipe 13 is connected to the two reaction chambers placed on different stoves. Its purpose is to make full use of the heat energy burned by the burners of different cooking stoves, and separate a part of the oily fumes and other harmful substances produced on the cooking stoves to the cooking stoves that are burning but do not produce oily smoke and harmful substances for processing. In this way, the power of the exhaust fan can be increased, so that oil fumes and other harmful substances can be sucked to the maximum extent, and the treatment efficiency is improved.

Embodiment 3

[0034] Embodiment three: it is a fixed oil fume treatment device, such as Figure 4 Shown, so-called fixed type refers to smoke collecting hood 7, parts such as exhaust fan 9 and ventilation pipe 13 link together, and be fixed on the wall as traditional range hood. The bent pipe of the ventilation pipe and the straight pipe of the ventilation pipe form a long ventilation pipeline and are connected to the reaction chamber 14 . The reaction chamber is the same as the reaction chamber in the previous two embodiments, and it is also placed on a certain stove eye of the stove 2, and the heat energy generated by burning gas in the stove eye burner provides the required high temperature and metal ventilation in the reaction chamber. The energy required to preheat the mixture in the tube. The oil fume collected by the fume collecting hood 7, odorous gas and other harmful substances enter the reaction chamber through the ventilation pipeline and are oxidized or decomposed by the oxyge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com