Dielectric procelain composition and electronic parts

A technology of dielectric ceramics and electronic devices, which is applied in the field of multilayer ceramic capacitors or other electronic devices, can solve the problems such as the easy reduction of insulation resistance life, and achieve the maintenance of insulation resistance life, high specific permittivity, and small capacitance aging characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

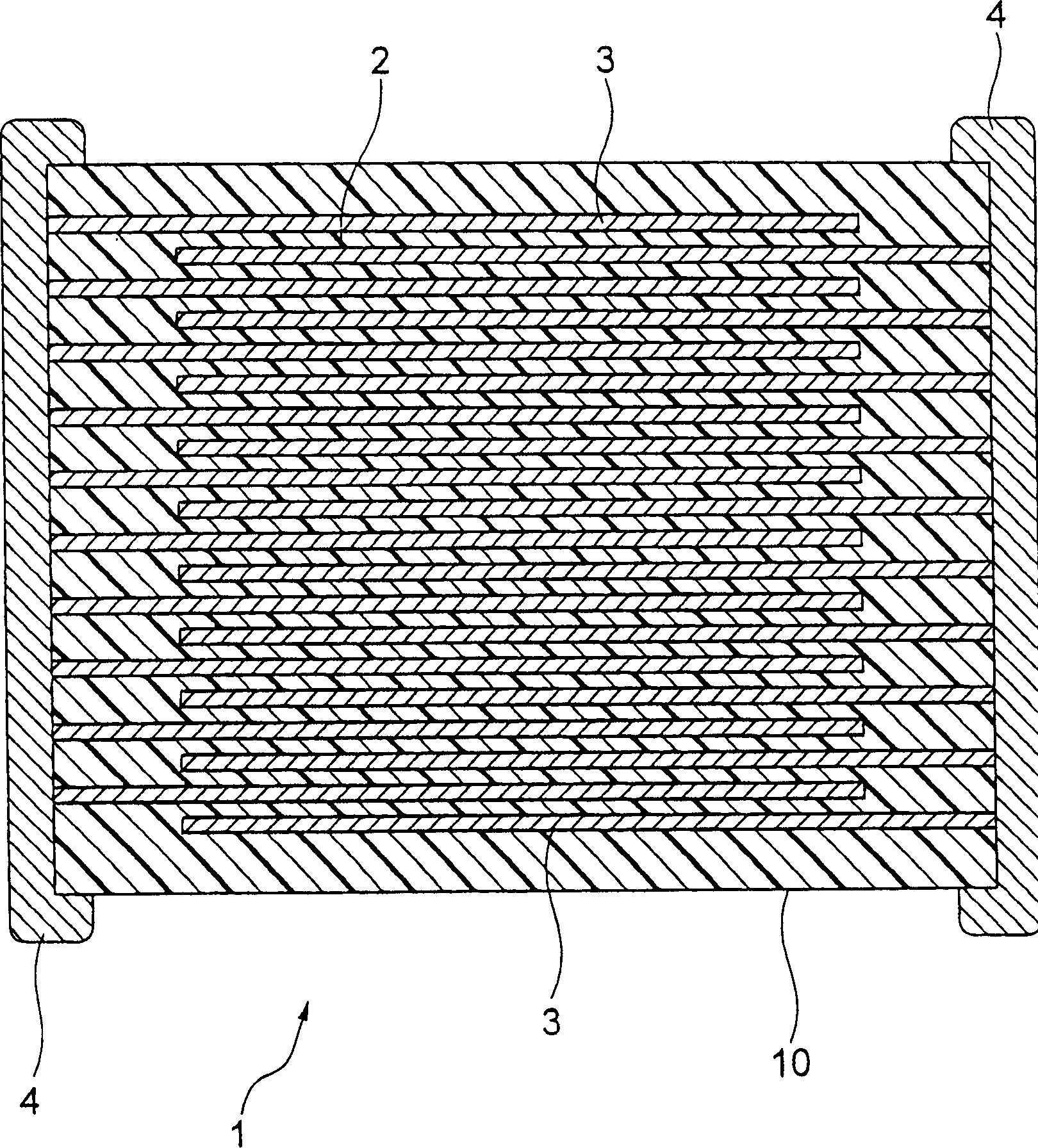

[0126] Production of capacitor samples

[0127] First, as a starting material for preparing a dielectric substance, a main component material (BaTiO 3 ) and first to fifth subcomponents having an average particle diameter of 0.1 to 1 micron, respectively. Use carbonate (first subcomponent: MgCO 3 , the fourth subcomponent: MnCO 3 ) for MgO and MnO materials, using oxides (second subcomponent: Y 2 o 3 , the third subcomponent: (Ba 0.6 Ca 0.4 ) SiO 3 , the fifth subcomponent: V 2 o 5 ) as other materials. Note that by using ball milling for BaCO 3 , CaCO 3 and SiO 2 Wet mixing was carried out for 16 hours, drying, firing in air at 1150 °C, and additional wet grinding using a ball mill for 100 hours, thus preparing (Ba 0.6 Ca 0.4 ) SiO 3 .

[0128] Note that by weighing BaCO separately using 3 and TiO 2 Prepare the main component BaTiO 3 , performed wet mixing using a ball mill for 16 hours, dried, fired at 1100°C in air, and further wet milled using a ball mil...

example 2

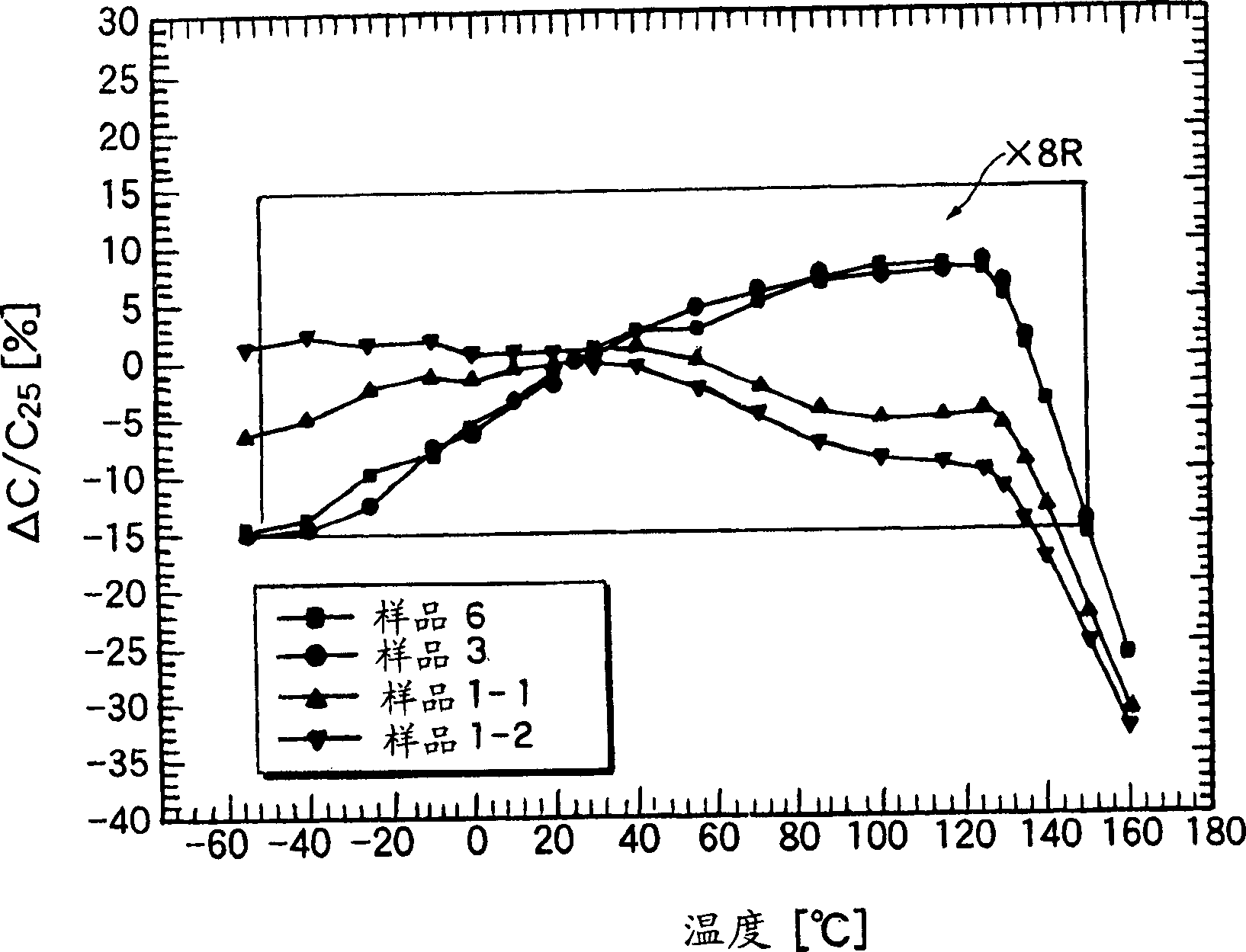

[0169] Capacitor samples were prepared in the same manner as Sample 3 of Example 1, except that the contents of the first subcomponent were changed to 0 mol (sample 6), 0.08 mol (sample 3), 1.0 mol (sample 1-1), and 2.06 mole (sample 1-2).

[0170] Capacitance was measured within a temperature range of -55 to 160°C, and the rate of change (ΔC / C) at each temperature was calculated relative to the capacitance at +25°C. The results are plotted in Table 2. As shown in Table 2, it was confirmed that when the content of the first subcomponent was reduced, the capacitance-temperature change rate on the high temperature side became small. That is, it has been confirmed that by decreasing the content of the first subcomponent, the plot points of the capacitance-temperature change rate on the high temperature side can be drawn in the counterclockwise direction of the graph.

example 3

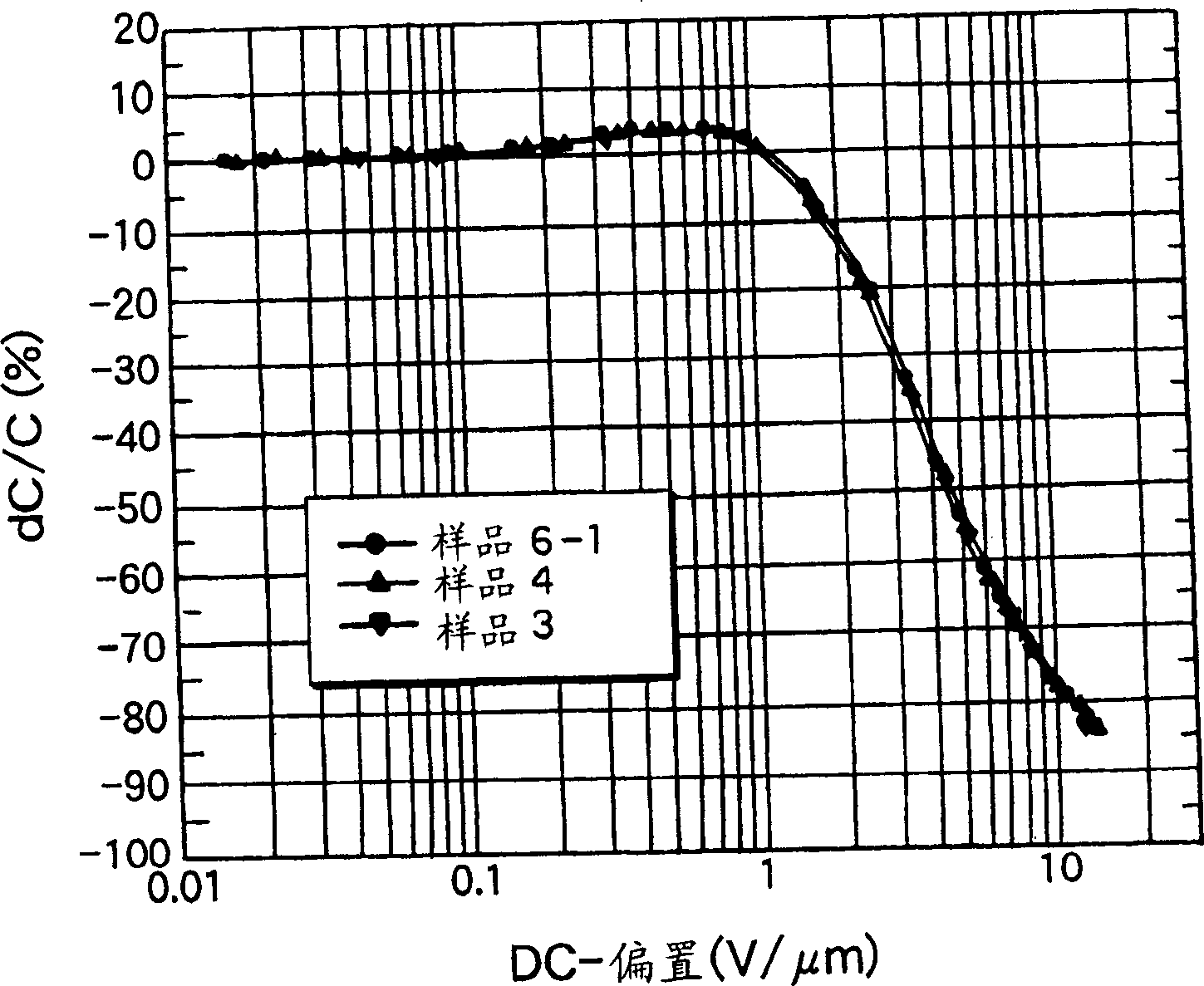

[0172] Capacitor samples were prepared in the same manner as Sample 3 of Example 1, except that the content of the first subcomponent was changed to 0.02 mol (sample 6-1), 0.04 mol (sample 4) and 0.08 mol (sample 3).

[0173] DC bias characteristics (depending on DC voltage application and dielectric constant) were evaluated from capacitor samples.

[0174] DC bias characteristics (dependence on DC voltage application and dielectric constant)

[0175] The DC bias characteristics were obtained by measuring the capacitance change (ΔC / C) by gradually applying a DC voltage to each capacitor sample at a constant temperature (25°C). The results are shown in image 3 . Such as image 3 As shown, it has been confirmed that when the content of the first subcomponent is within the range of the present invention, even if a high voltage is applied, the capacitance is hardly reduced, resulting in stable DC bias characteristics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com