Improving method for preparing (poly) isocyanate by gas phase

A technology of isocyanate and phosgene, applied in the field of isocyanate production, can solve problems such as undesired parallel or subsequent reactions, increased thermal decomposition of products, and uneven temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

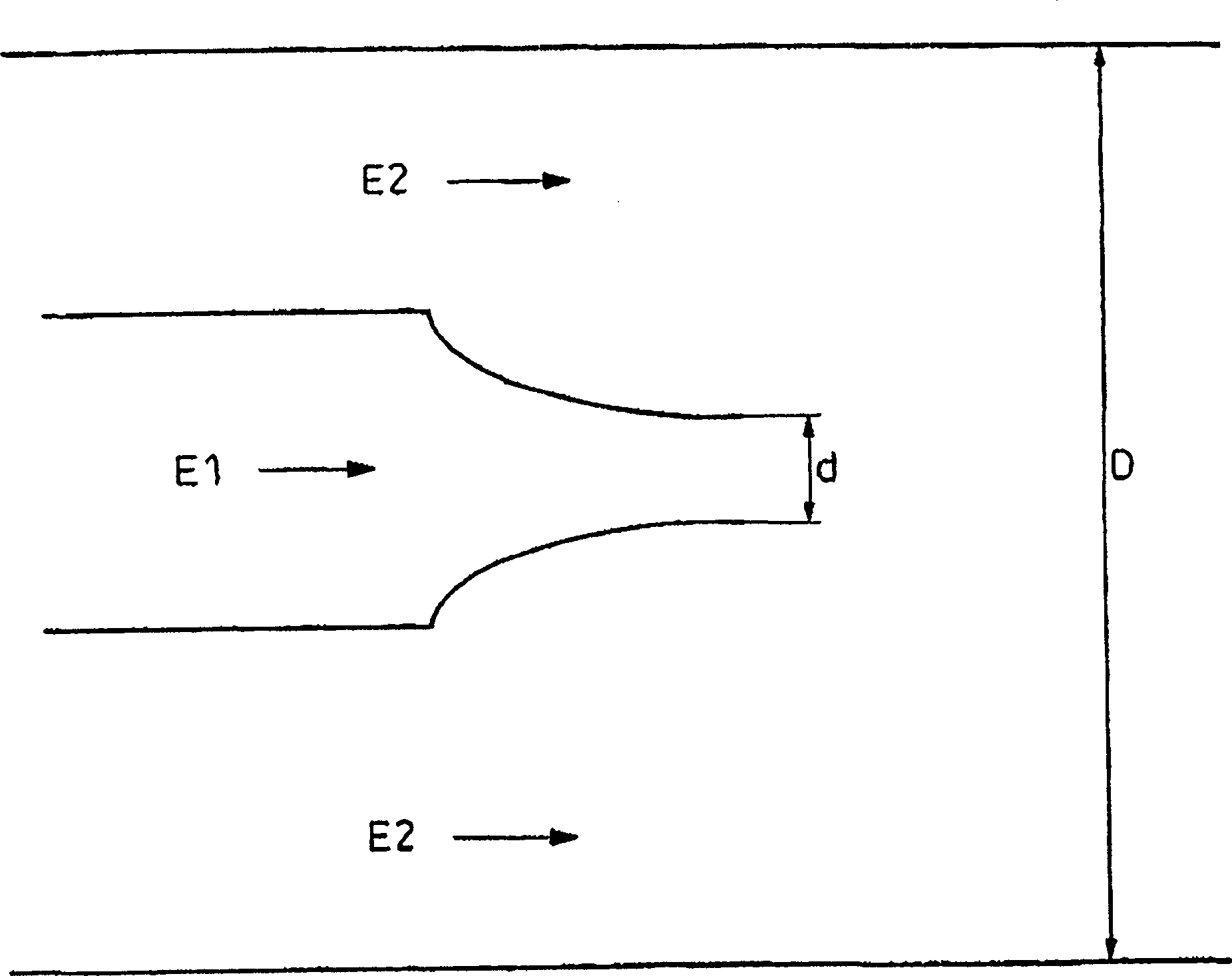

[0044] Isophoronediamine (IPDA), phosgene and nitrogen in a molar ratio of 1:4:0.1 are continuously flowed into the stage with downstream diisocyanate condensation (and subsequent isocyanate processing) in the mixing tube. The educts were evaporated separately from each other in an upstream heat exchanger and adjusted to a temperature of 320°C. A mixture of nitrogen and IPDA (E1) flows through the nozzle, while phosgene (E2) flows through the annular space around the nozzle. The diameter ratio between nozzle (d) and reaction chamber (D) is 0.18:1. The pressure in the reaction zone is slightly above atmospheric pressure. The flow velocity of the reaction mixture downstream of the nozzle is about 20 m / s. After leaving the reactor, the reaction product isophorone diisocyanate (IPDI) is condensed and separated from excess phosgene and secondary products, hydrogen chloride, and sent for purification. The yield of IPDI relative to the incorporated IPDA was 98.8% of theory. This...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com