Assembling type axial cam knurling type connection automatic assembling machine

A camshaft and knurling technology, which is applied in the field of automatic connecting devices, can solve the problems of connecting press-in, uneven mandrel knurling, etc., and achieve the effects of increasing the pressing force, saving time, and saving connection and assembly time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

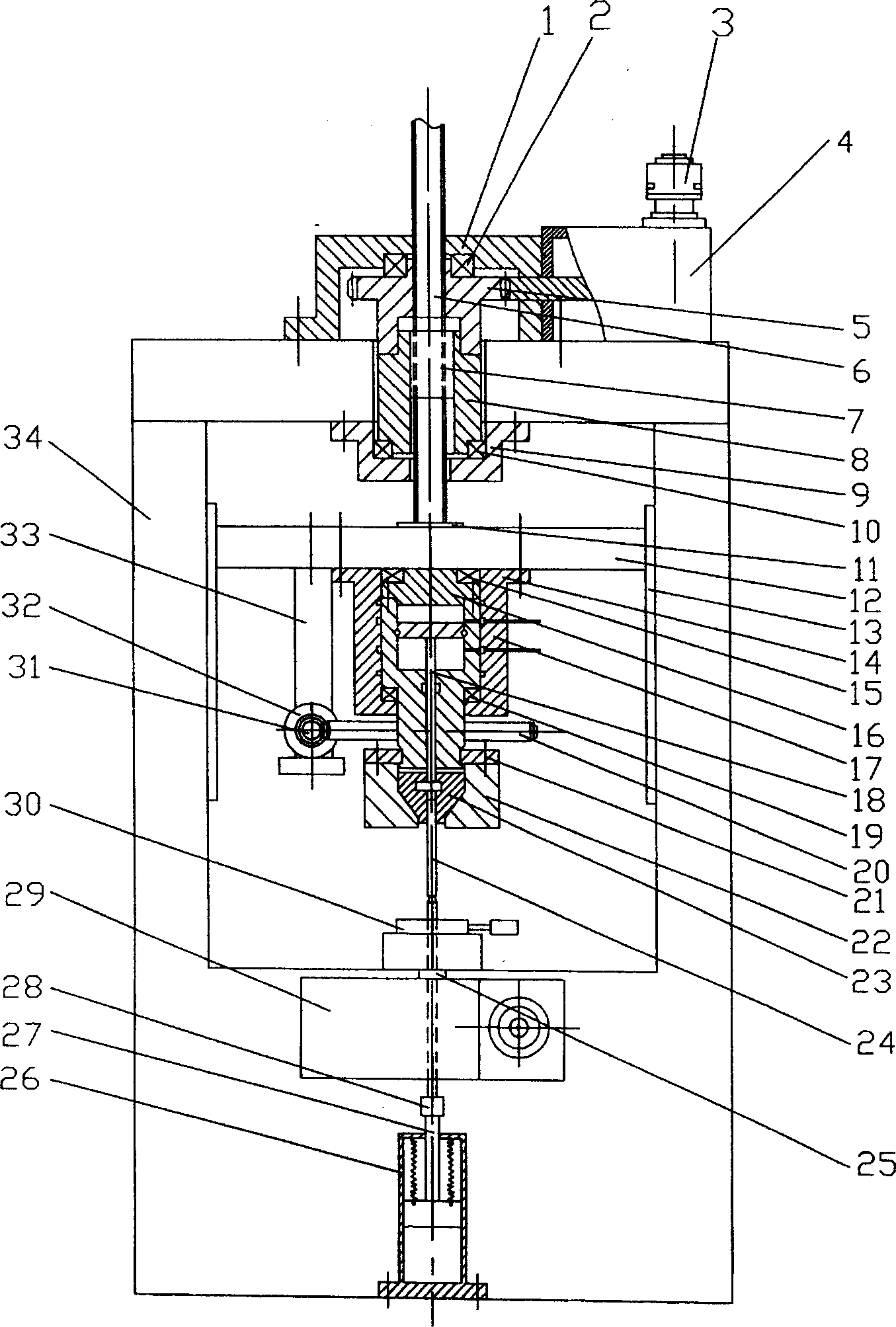

[0015] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

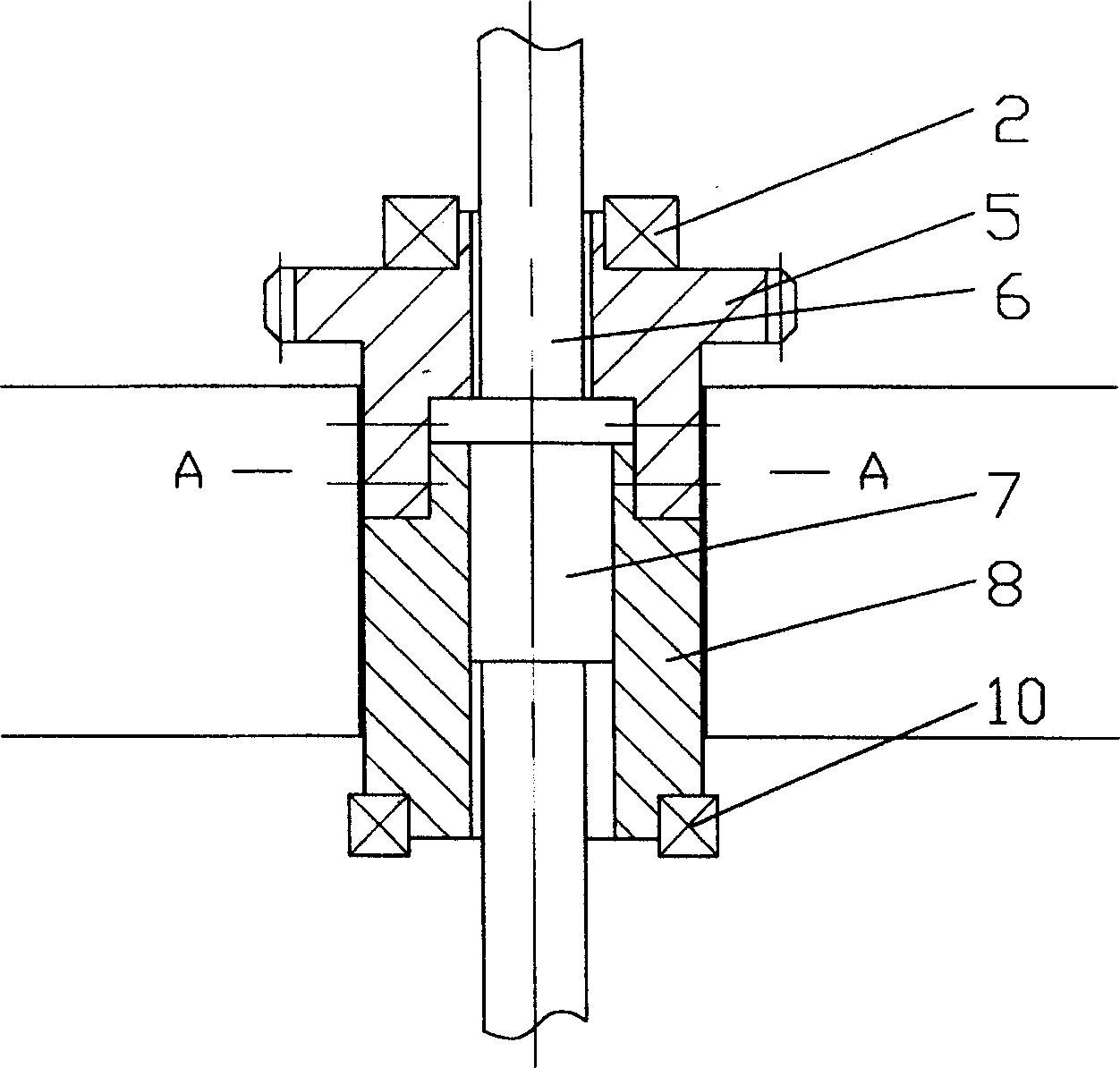

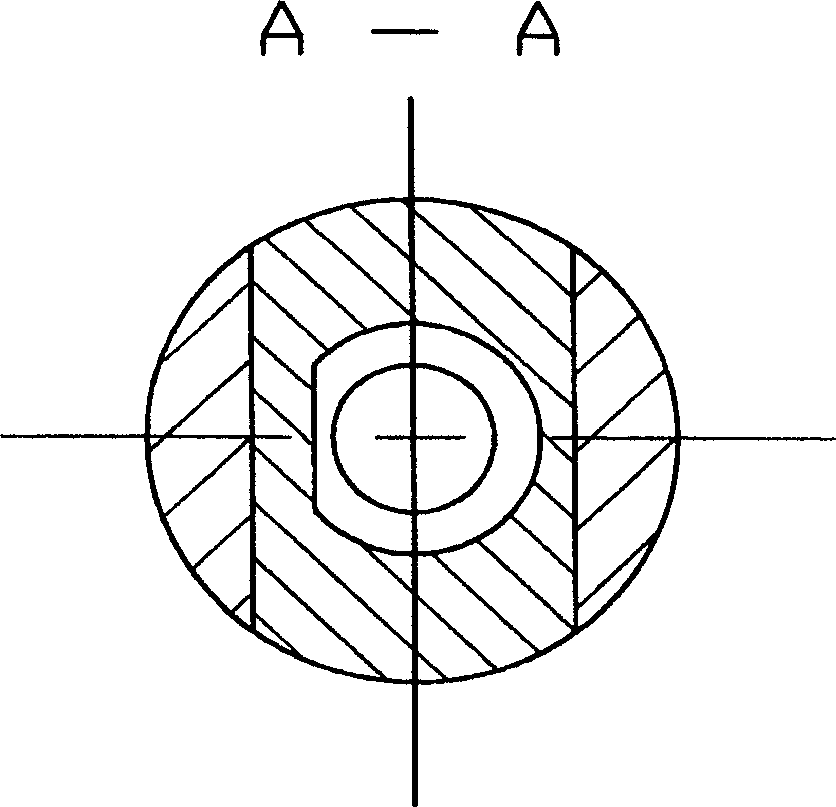

[0016] refer to figure 1 : the present invention adopts the method that knurling and assembling are carried out simultaneously to design. The knurling device 30 is installed above the camshaft assembly position (that is, the position where the cam 25 is placed). First, under the downward push of the cylinder push rod 18, the chuck 23 clamps the mandrel 24 of the camshaft, and the motor 3 can be an AC servo motor, which drives the transmission gear 5 to rotate through the high-speed transmission ratio mechanism of the gear box 4. The gear 5 is connected with the nut 7 of the ball screw 6, which drives the nut 7 to rotate, and the ball screw 6 moves down quickly. Sliding, the lower end of the slide block 12 is connected with the mandrel 24 clamping rotation mechanism. Since the ball screw 6 moves dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com