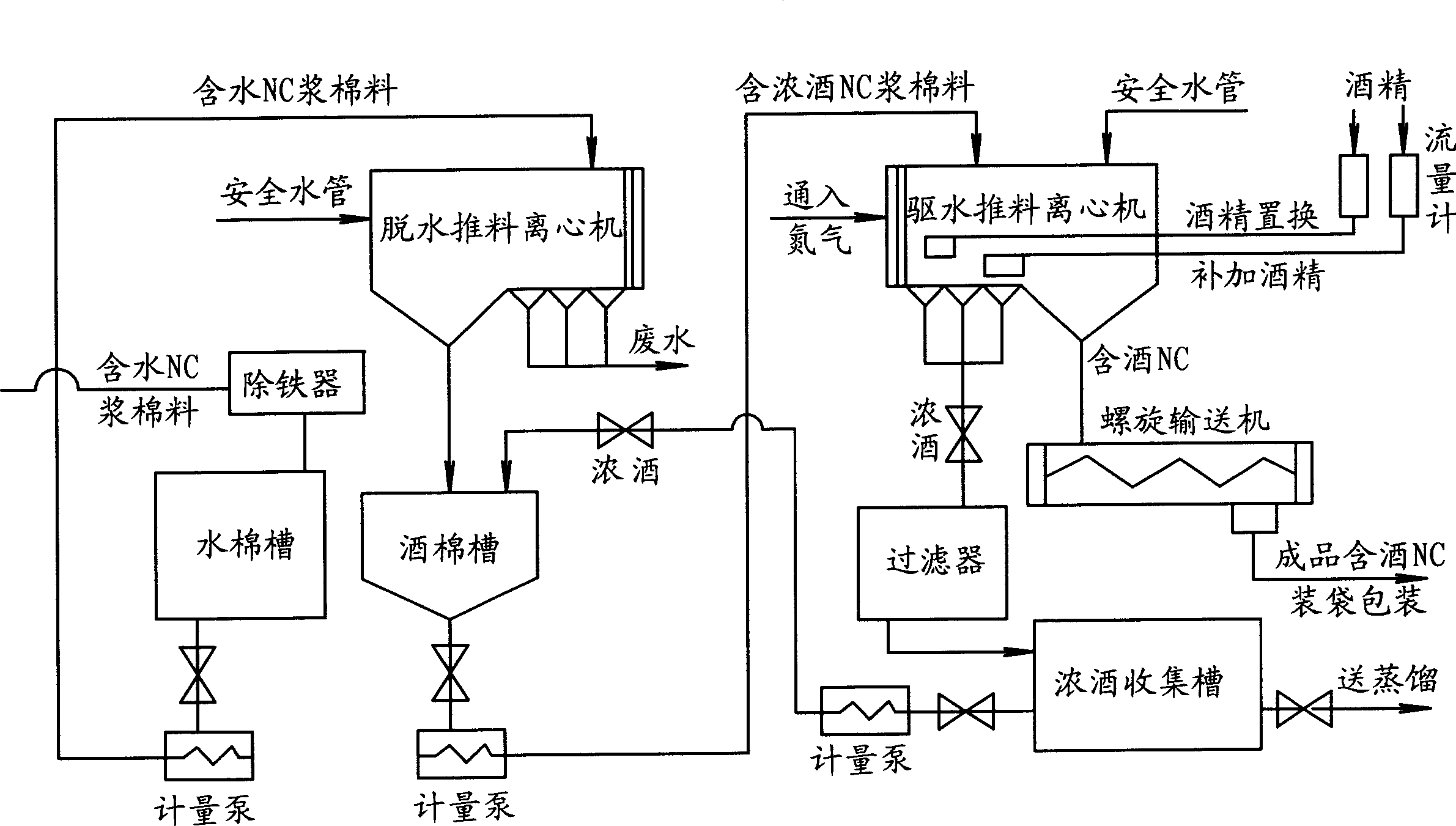

Continuous nitrocotton dewatering process and apparatus

A nitrocellulose and water-displacement technology, applied in the field of water-displacement technology and devices, can solve problems such as inability to continuously displace water, and achieve the effects of improved working environment and conditions, good reproducibility, and reliable technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 is that the method of the present invention is used to produce the coating nitrocellulose of 1 / 4 second grade, and its process step and parameter are as follows:

[0042] ①The nitrocellulose slurry enters the dehydrated cotton tank, and the cotton pulp concentration is adjusted, and the cotton pulp concentration is (9±1)%;

[0043] ②The nitrocellulose slurry is poured into the double-stage piston pusher centrifuge for dehydration by the metering pump for dehydration. The dehydration speed is controlled by the frequency converter and the metering pump for dehydration. The dehydration speed is (35±2%) Kg / min, and the metering Pump speed (750±25)r / min;

[0044] ③ After the dehydration, the moisture content of the nitrocellulose is ≤29%. ±3)%;

[0045] ④The wine cotton is pumped into the water by the metering pump, and the two-stage piston pusher centrifuge is used to replace the alcohol with water, and the metering pump is controlled by the frequency converter...

Embodiment 2

[0046] Embodiment 2 is that the method of the present invention is used to produce the nitrocellulose for the coating of 1 / 2 second grade, and its processing steps and parameters are as follows:

[0047] ①The nitrocellulose slurry enters the dehydrated cotton tank, and the cotton pulp concentration is adjusted, and the cotton pulp concentration is (8±1)%;

[0048] ②The nitrocellulose slurry is pumped into the two-stage piston pusher centrifuge for dehydration by the metering pump for dehydration. The dehydration speed is controlled by the frequency converter and the metering pump for dehydration. The dehydration speed is (33±2)Kg / min, and the metering pump for dehydration Speed (600±25)r / min;

[0049] ③ After the dehydration, the moisture content of the nitrocellulose is ≤29%. ±3)%;

[0050] ④The wine cotton is pumped into the water by the metering pump, and the two-stage piston pusher centrifuge is used to replace the alcohol with water, and the metering pump is controlle...

Embodiment 3

[0051] Embodiment 3 is that the method of the present invention is used to produce the nitrocellulose for the coating of 30 seconds grade, and its processing steps and parameters are as follows:

[0052] ①The nitrocellulose slurry enters the dehydrated cotton tank, and the cotton pulp concentration is adjusted, and the cotton pulp concentration is (6±1)%;

[0053] ②The nitrocellulose slurry is pumped into the two-stage piston pusher centrifuge for dehydration by the metering pump for dehydration. The dehydration speed is controlled by the frequency converter and the metering pump for dehydration. The dehydration speed is (30±2)Kg / min, and the metering pump for dehydration Speed (800±25)r / min;

[0054] ③ After dehydration, the moisture content of the nitrocellulose is ≤29%. ±3)%;

[0055] ④The wine cotton is pumped into the water by the metering pump, and the two-stage piston pusher centrifuge is used to replace the alcohol with water, and the metering pump is controlled by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com