Bearing slip-in material and making method

A manufacturing method and a technology of bearings, which are applied to bearing components, shafts and bearings, earthwork drilling, etc., can solve problems such as poor friction reduction and anti-seizing performance, unsatisfactory load-bearing performance, and insufficient service life, etc., and achieve friction reduction Effect of improved performance and wear resistance, smooth bearing torque and temperature, high strength and load carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

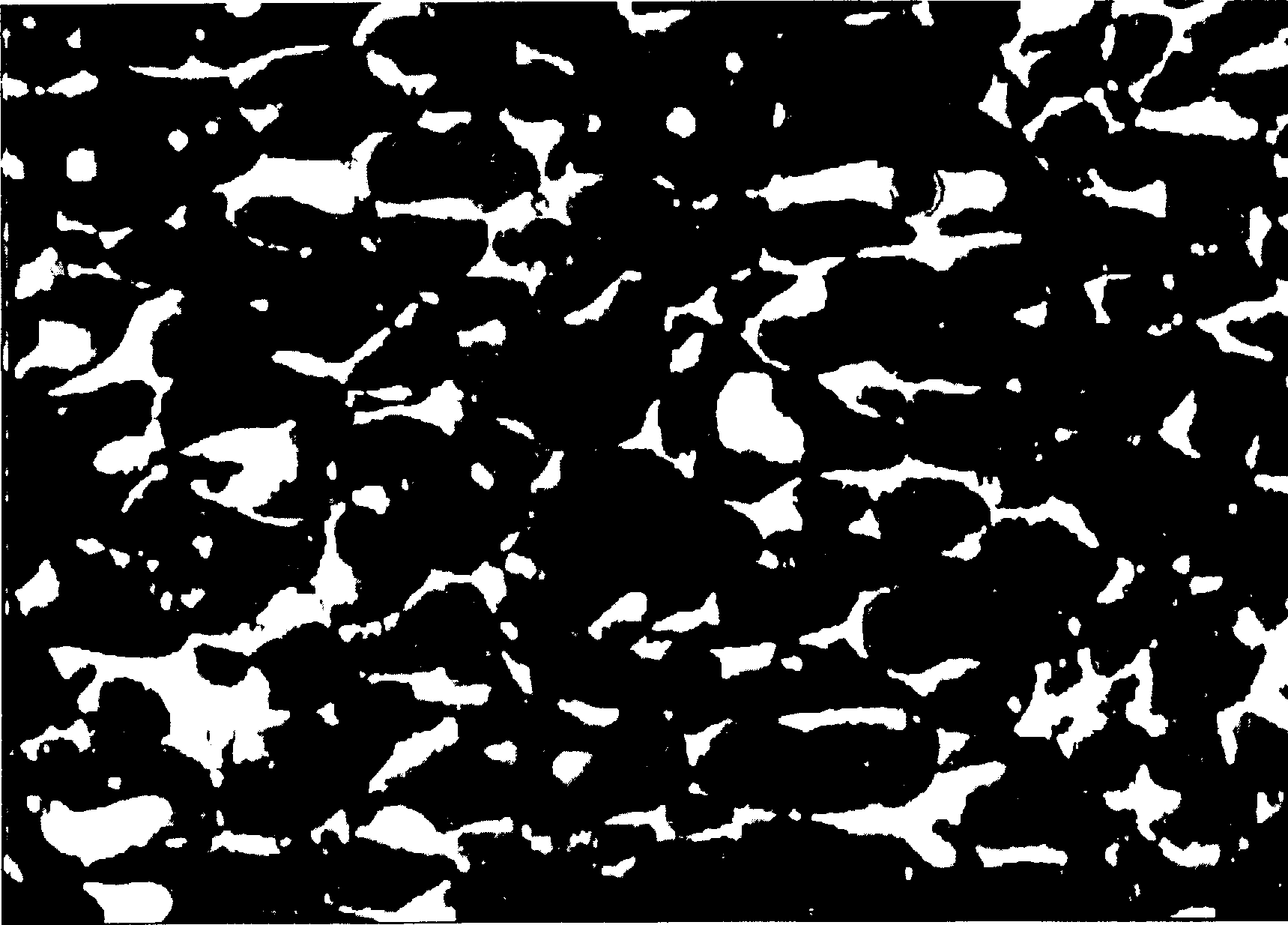

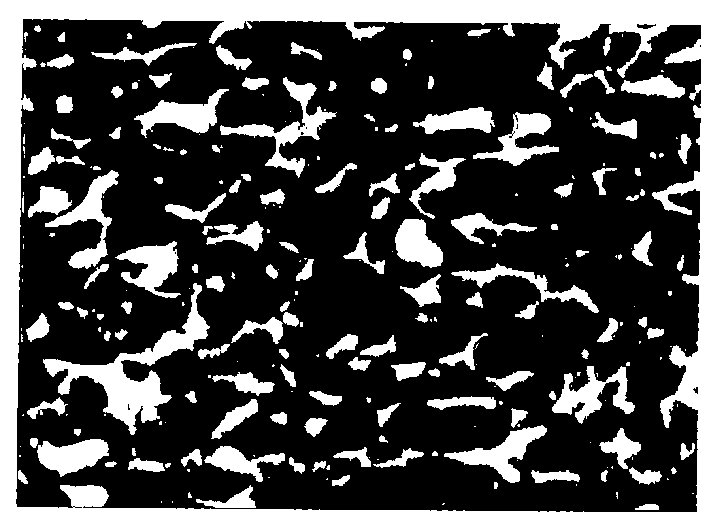

Image

Examples

Embodiment 1

[0022] The raw material ratio of the steel-based porous skeleton is: Cu2%, Mo1%, C2%, Fe balance, the infiltration agent is pure Cu infiltration agent, the steel-based porous skeleton is vacuum sintered at 1130-1150 °C, the steel-based The density of the porous skeleton is controlled at 6.2-6.5g / cm 3 Within the range, after vacuum sintering and infiltration at 1130-1150°C for 60 minutes, the infiltration amount of pure Cu is between 14-20% of the total weight of the material by weight, and the density of the made insert bearing material is 7.6-8.0g / cm 3 . In the bearing experiment, the average bearing capacity can reach 96.6KN at a speed of 166rpm, and the bearing capacity has increased by 38% year-on-year.

Embodiment 2

[0024] The raw material ratio of the steel-based porous skeleton is by weight: Cu5%, Ni2%, Cl%, Fe balance, infiltration agent is pure Cu-5%Fe-5%Mn (Fe5%, Mn5%, Cu balance ) copper-based infiltration agent, the steel-based porous skeleton is sintered under the protection of hydrogen at 1120-1140 °C, and infiltrated with hydrogen protection at 1130-1150 °C for 80 minutes. In the bearing experiment, the average bearing capacity can reach 112.1KN at a speed of 166rpm, and the bearing capacity has increased by 60% year-on-year.

Embodiment 3

[0026] The raw material ratio of the steel-based porous framework is by weight: Cu2%, Ni2%, C1.5%, Fe balance, the infiltration agent is pure Ag infiltration agent, and the steel-based porous framework is protected by hydrogen at 1130-1150 °C It is sintered and infiltrated with hydrogen protection at 1100-1120°C for 60 minutes. The average bearing capacity of the bearing test can reach 90.2KN at 166rpm, and the bearing capacity has increased by 30% year-on-year.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com