Organic white-light diode colour dispaly device of active addressing front-set colour film

A color film and diode technology, which is applied in the field of active site selection pre-color film organic white light diode color display and preparation, can solve the problems of higher alignment accuracy, difficult light-emitting diode process, and increased production cost, etc., to achieve Improvement of productivity and reduction of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

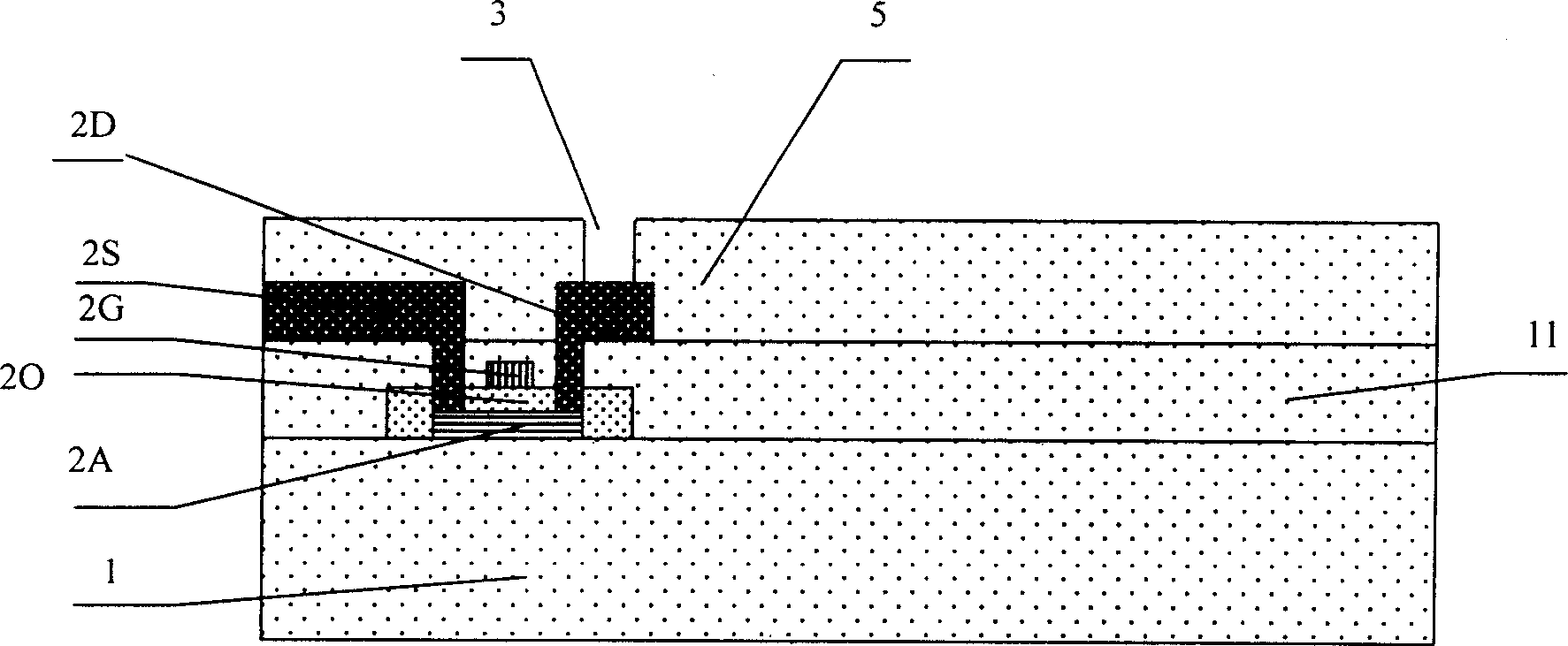

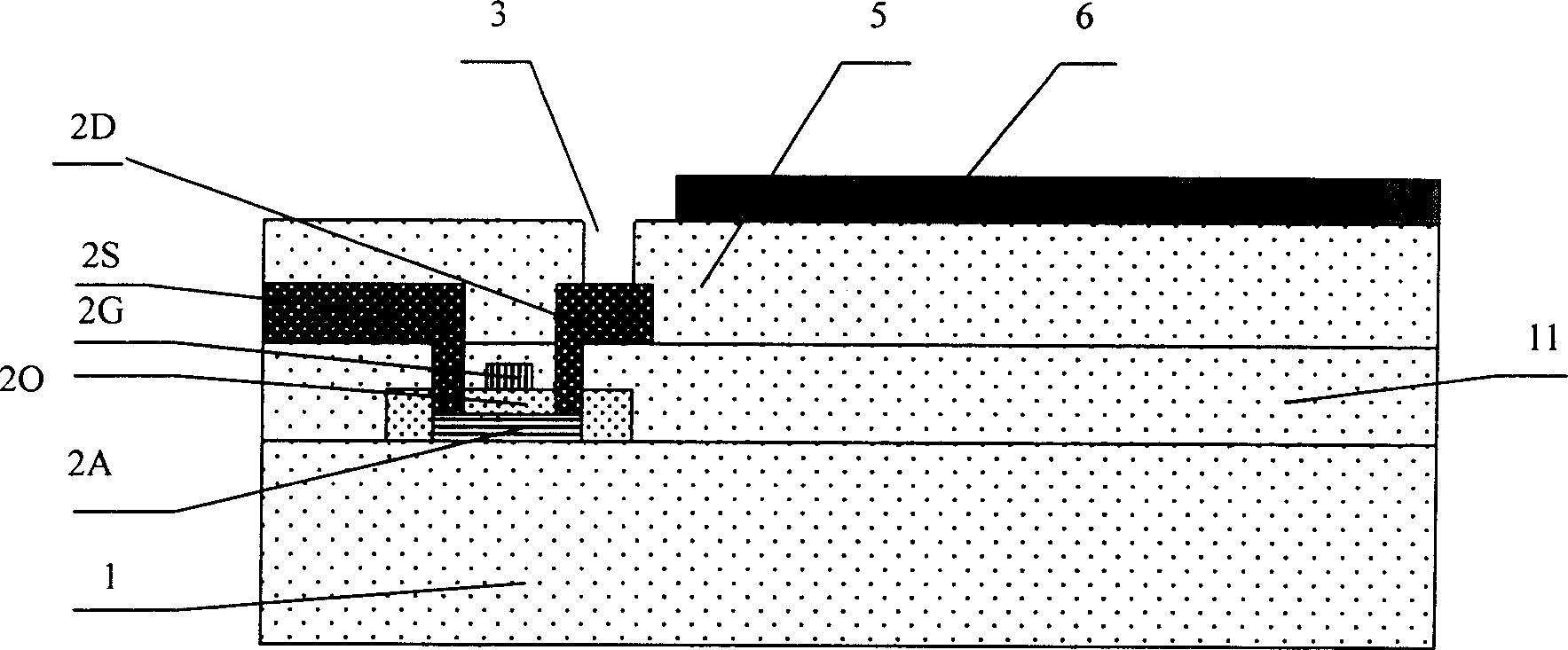

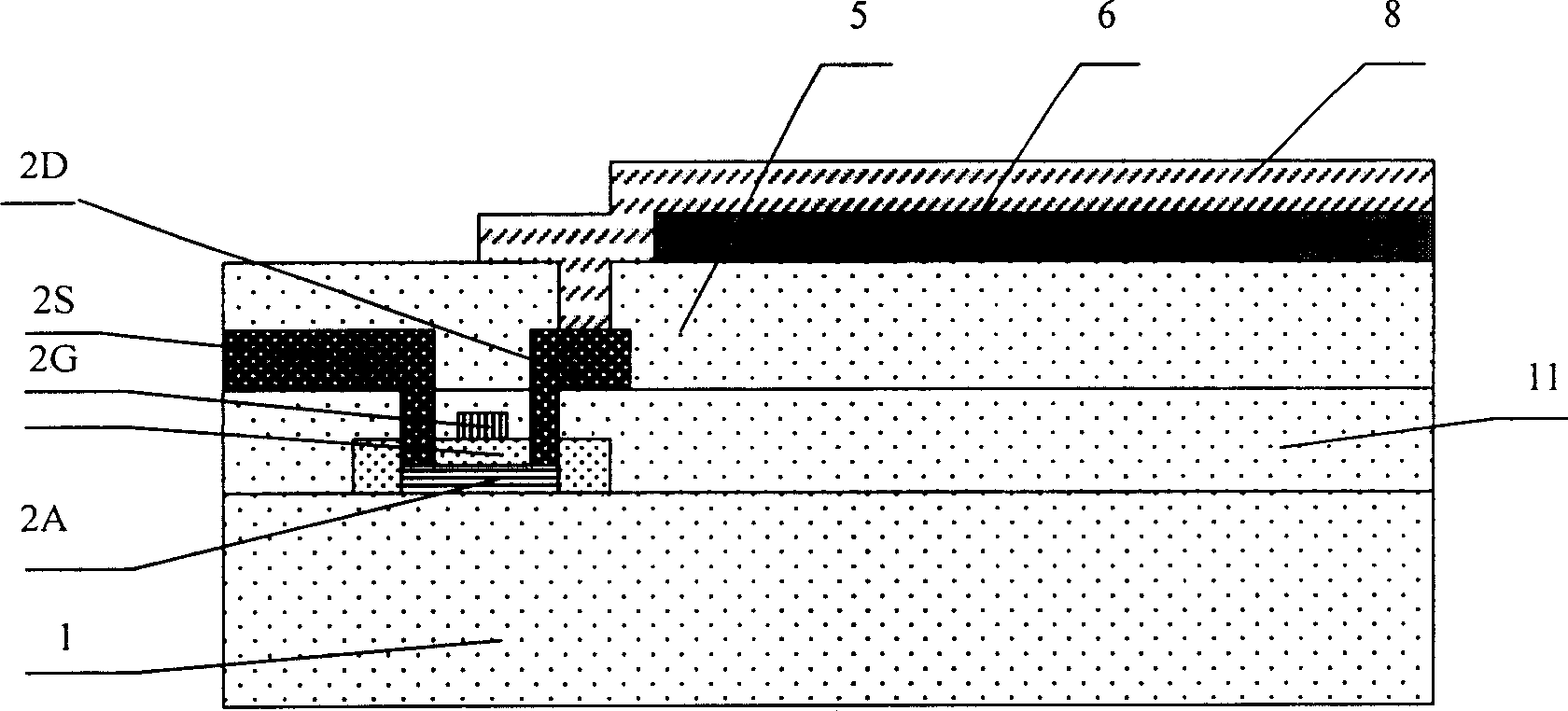

[0037] The present invention is described in detail as follows with reference to accompanying drawing:

[0038] As shown in the figure, the present invention uses a polysilicon thin film transistor matrix on a transparent glass substrate (1737 glass produced by Corning Corporation of the United States) 1 as an active addressing substrate. The thin film transistor includes an active layer 2A close to a transparent glass substrate, on and around the active layer 2A is a silicon oxide insulating layer 2O, on the silicon oxide insulating layer 2O is a gate 2G, and on the gate 2G is another layer The silicon oxide insulating layer 11, the source 2S and the drain 2D are connected to the active layer 2A through the silicon oxide insulating layers 11 and 2O. On the active substrate is a silicon oxide insulating layer 5, and in the silicon oxide insulating layer 5 there is a contact hole 3 connected to the drain electrode 2D of the driving tube. On the silicon oxide insulating layer 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com