Organic electric-exciting light emitting device and its making method

A technology of electroluminescence and production method, which is applied in the direction of electroluminescence light source, electric light source, lighting device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

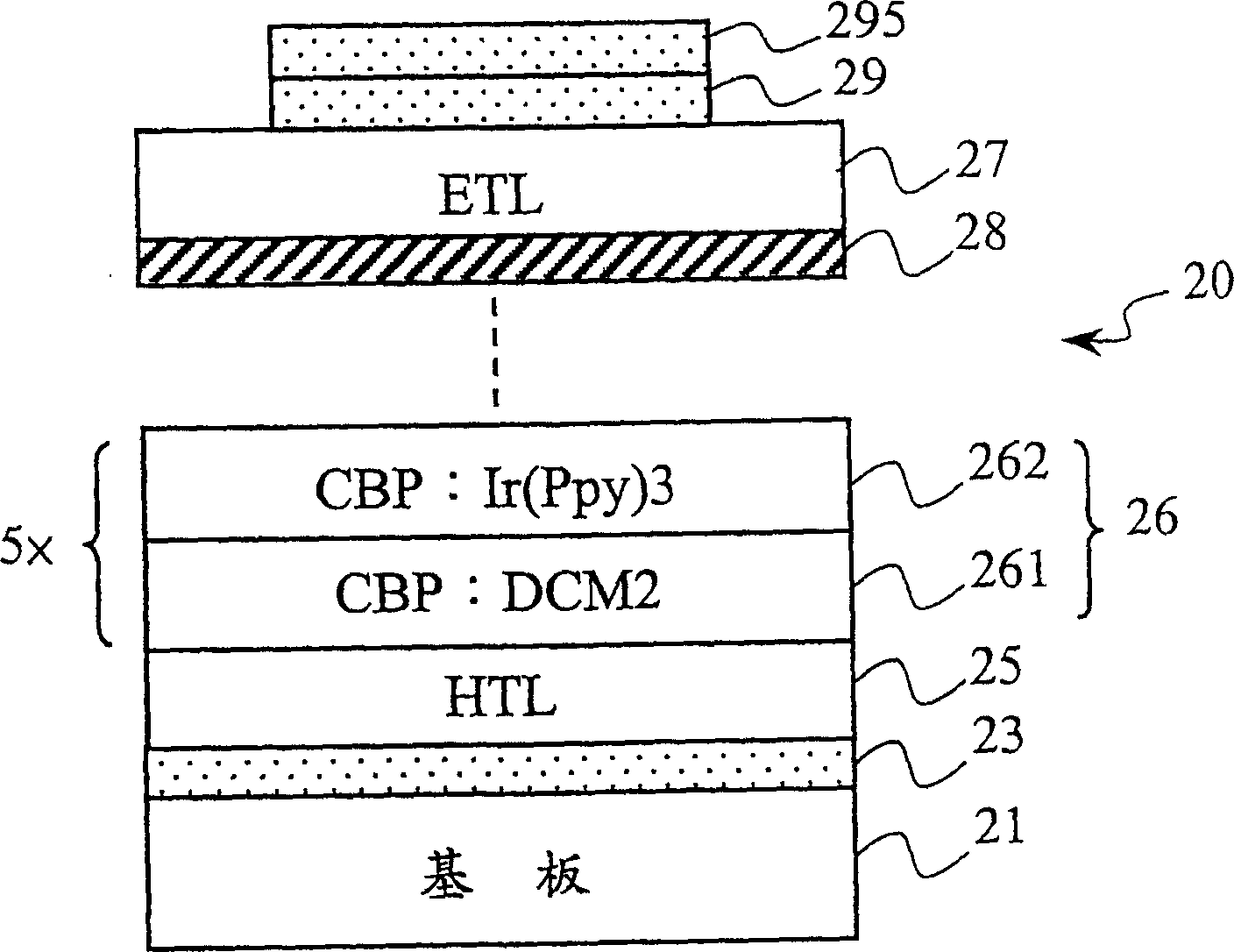

[0041] First, see Figure 4 , is a structural sectional view of a preferred embodiment of the present invention. As shown in the figure, the organic electroluminescent device 30 of the present invention mainly forms a first conductive layer 33 (such as an anode) on the upper side of a light-transmitting substrate 31 by evaporation or sputtering, and on the upper side of the anode 33 On the upper side, a hole injection layer 53 (HIL; the first carrier injection layer), a hole transport layer 35 (HTL; the first carrier transport layer) and a layer with a barrier to the second carrier (electron) are formed in sequence. Electronic blocking layer 47 (electron blocking layer), the upper side of the electronic blocking layer 47 is formed with a first host material layer 41 (Host 1) and a second host material layer 43 (Host2) in sequence, and on the second host material layer On the upper side of 43, a hole blocking layer 45 (hole blocking layer), an electron transport layer 37 (ETL;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com