Method for measuring motor constant of induction motor

A technology of induction motor and electric motor, which is applied in the estimation/correction of motor parameters, motor generator testing, motor control in four quadrants, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

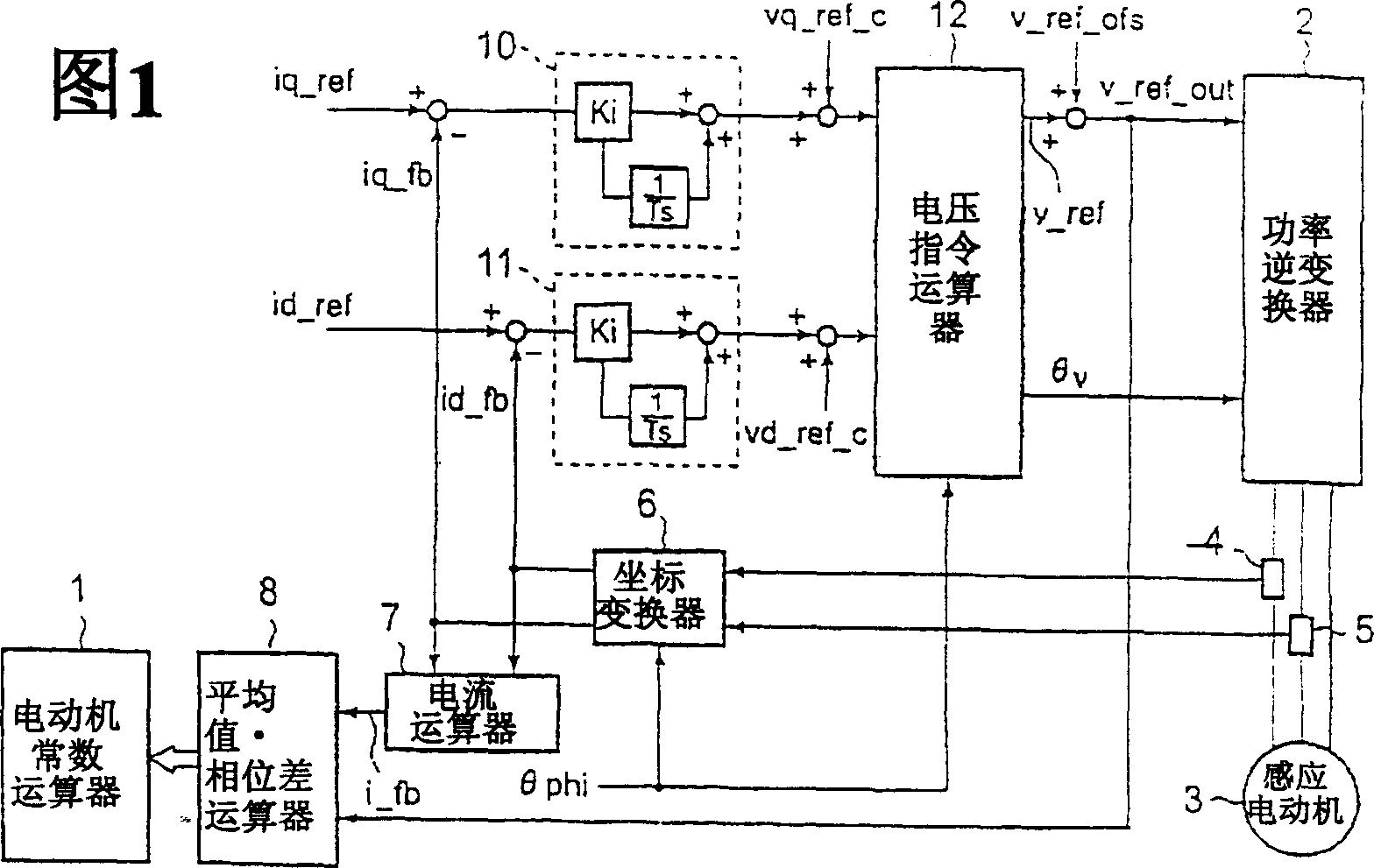

[0052] Fig. 1 is a block diagram showing the configuration of an embodiment of an induction motor control device according to the present invention. The proportional-integral controller 10 is used to control the deviation between the q-axis current command iq_ref and the q-axis current detection value iq_fb to make it zero, and add the q-axis auxiliary voltage command vq_ref_c to the output of the proportional-integral controller 10 to generate the q-axis voltage command vq_ref. Similarly, the proportional-integral controller 11 is used to control the deviation between the d-axis current command id_ref and the d-axis current detection value id_fb to make it zero, and add the d-axis auxiliary voltage command vd_ref_c to the output of the proportional-integral controller 11 to generate d Shaft voltage command vd_ref. The proportional gain of the proportional-integral controller is expressed as Ki, and the integral gain is expressed as (1 / T). The voltage command calculator 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com