Production equipment of crude soybean micro powder possessing high functional full fat activity

A technology of fine powder and manufacturing equipment, which is applied in food forming, plant protein processing, food science, etc. It can solve the problems of fishy smell, indigestion, difficulty in storage, deterioration of soybean fat, etc., and achieve improved digestion and absorption rate and easy crushing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

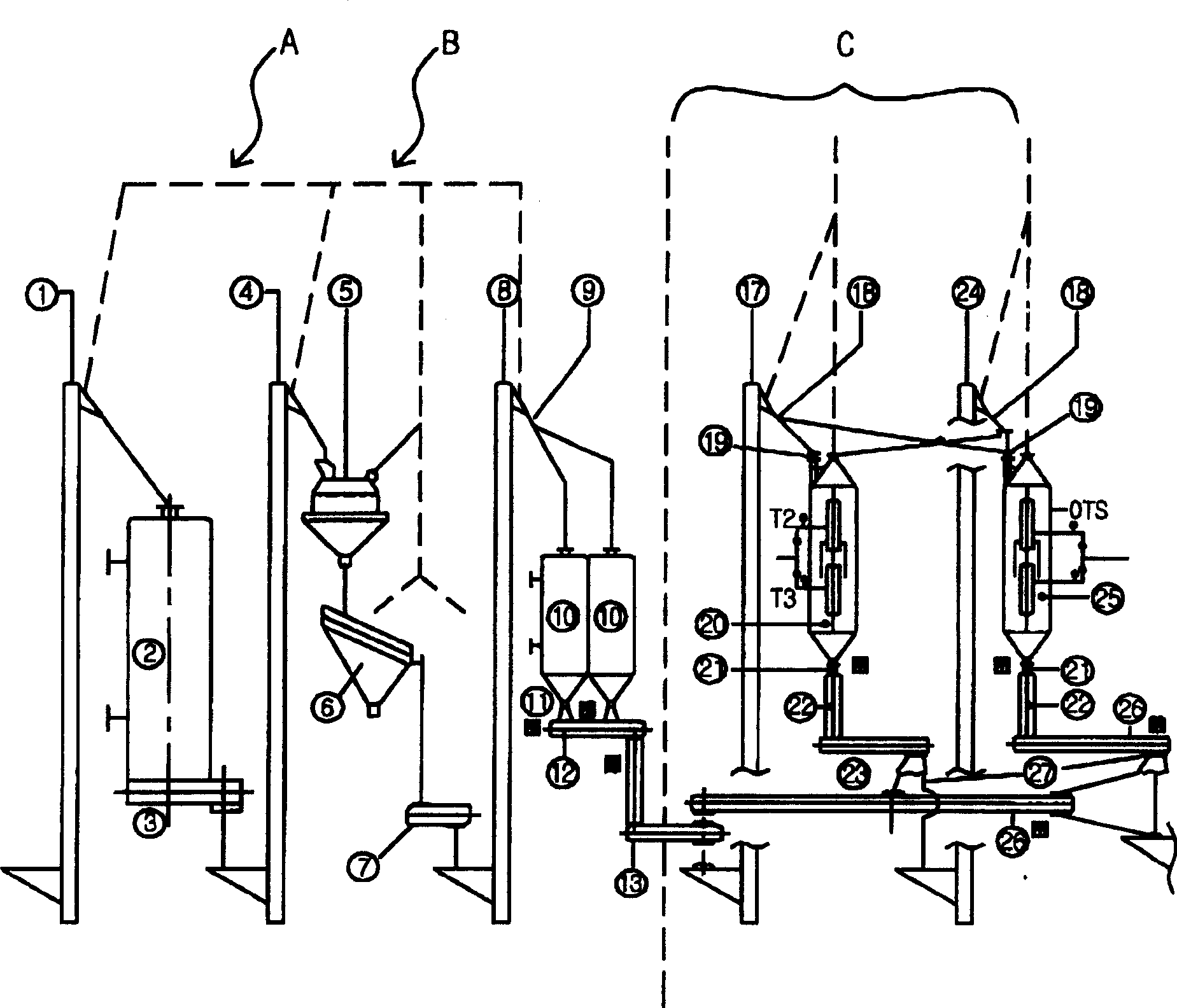

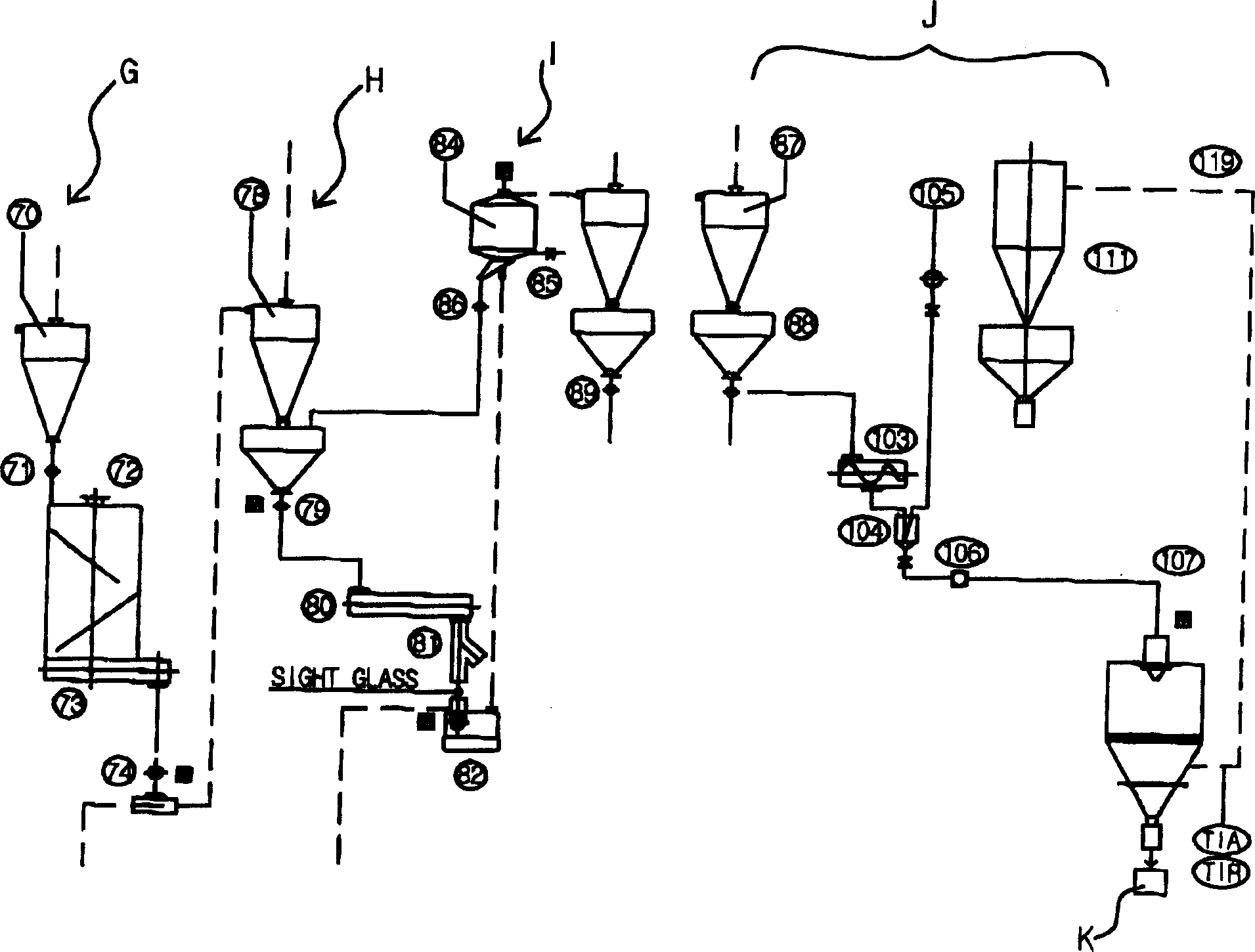

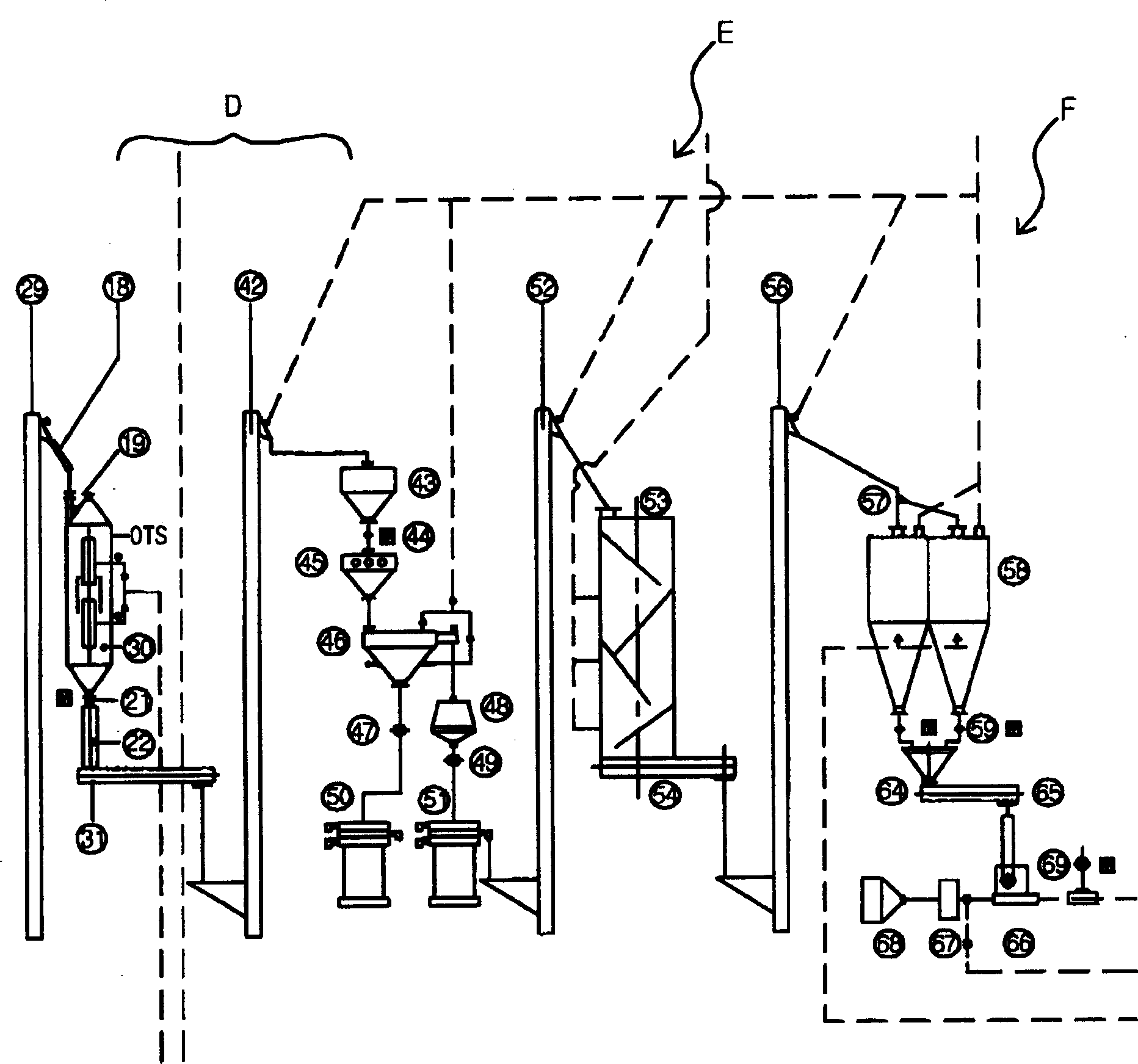

[0029] In order to achieve the above-mentioned technical purpose, the present invention has been described in detail according to the accompanying drawings, which are described as follows:

[0030] Such as figure 1 As shown, the equipment in the present invention is not only able to realize the transportation and storage of raw soybeans and smooth input and discharge, but also has storage equipment (A) with a storage box that can adjust its storage capacity up, down, and down;

[0031] The selection on one side of the storage box transfers the foreign matter in the raw soybean (bean skin, rotten beans, soil, stone, iron powder, etc.) to the foreign matter selection equipment (B) and;

[0032] The first drying equipment (C) for drying raw soybeans with moisture content of 15-18% without heat denaturation into soybeans with moisture content of 8-10%;

[0033] Use cooling equipment to cool the above-mentioned dried soybeans with a moisture content of 8-10% to 15-20°C, cut them ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com