Non equeous electrolyte battery

A non-aqueous electrolyte and battery technology, applied in non-aqueous electrolyte batteries, non-aqueous electrolyte batteries, electrolyte battery manufacturing, etc., can solve the problems of high self-discharge and poor storage resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

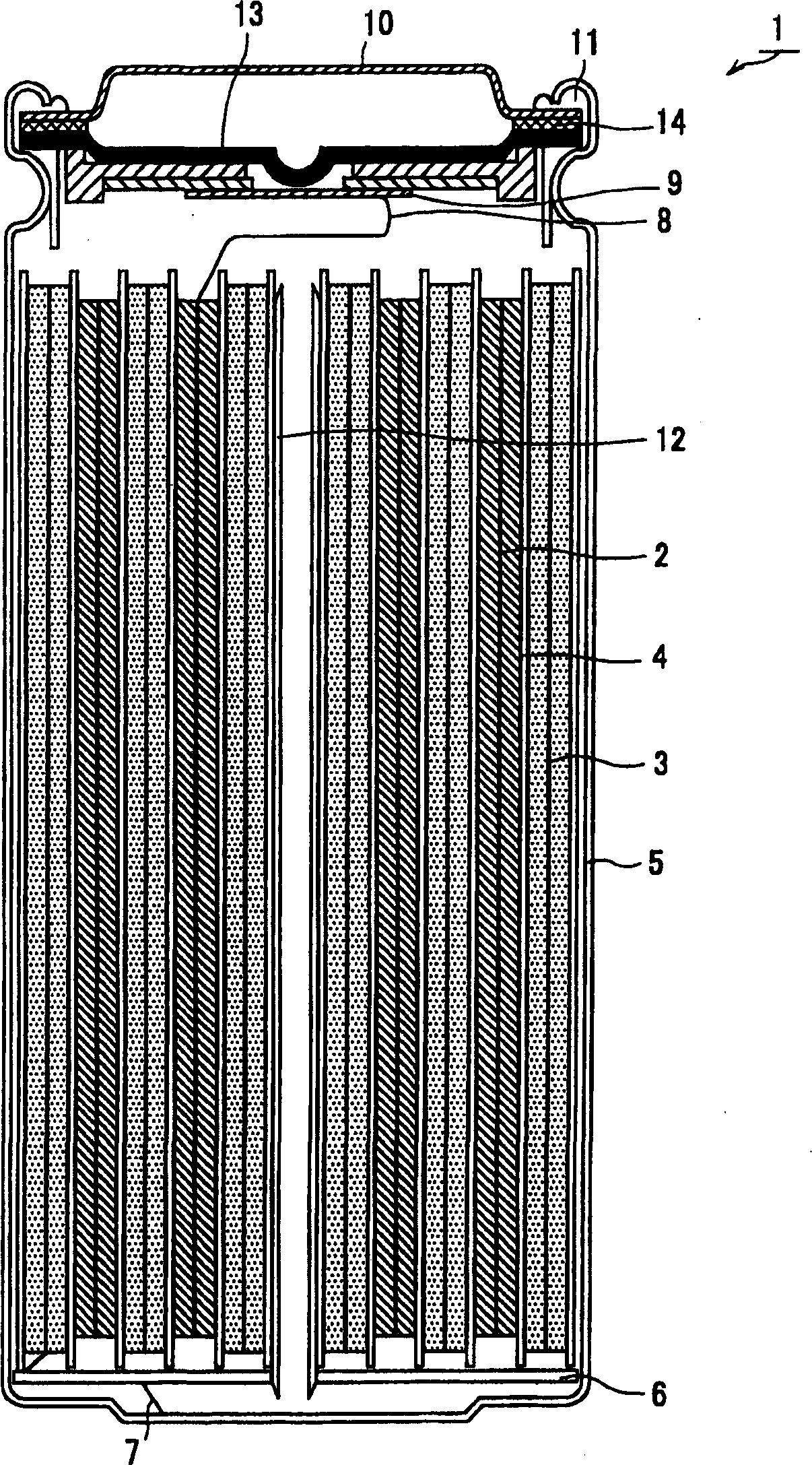

[0045] First, an elongated anode is fabricated as follows. Calculated by weight, 90 parts of graphite as negative electrode active material and 10 parts of polyvinylidene fluoride as binder were mixed together to prepare an anode composite mixture. These anode complex mixtures were dispersed in N-methyl-2-pyrrolidone to obtain slurries.

[0046] For the anode current collector, an elongated copper foil with a thickness of 10 μm can be used. The anode complex mixture slurry is coated on both surfaces of this current collector, dried, and the obtained product is molded under a prescribed pressure. The resulting product was cut into elements with a width of 56 mm, thereby forming elongated anodes.

[0047] On the other hand, an elongated cathode was produced in the following manner. First, a positive electrode active material was produced in the following manner. In order to obtain the positive electrode active material (LiCoO 2 ), lithium carbide and cobalt carbonate were m...

example 2

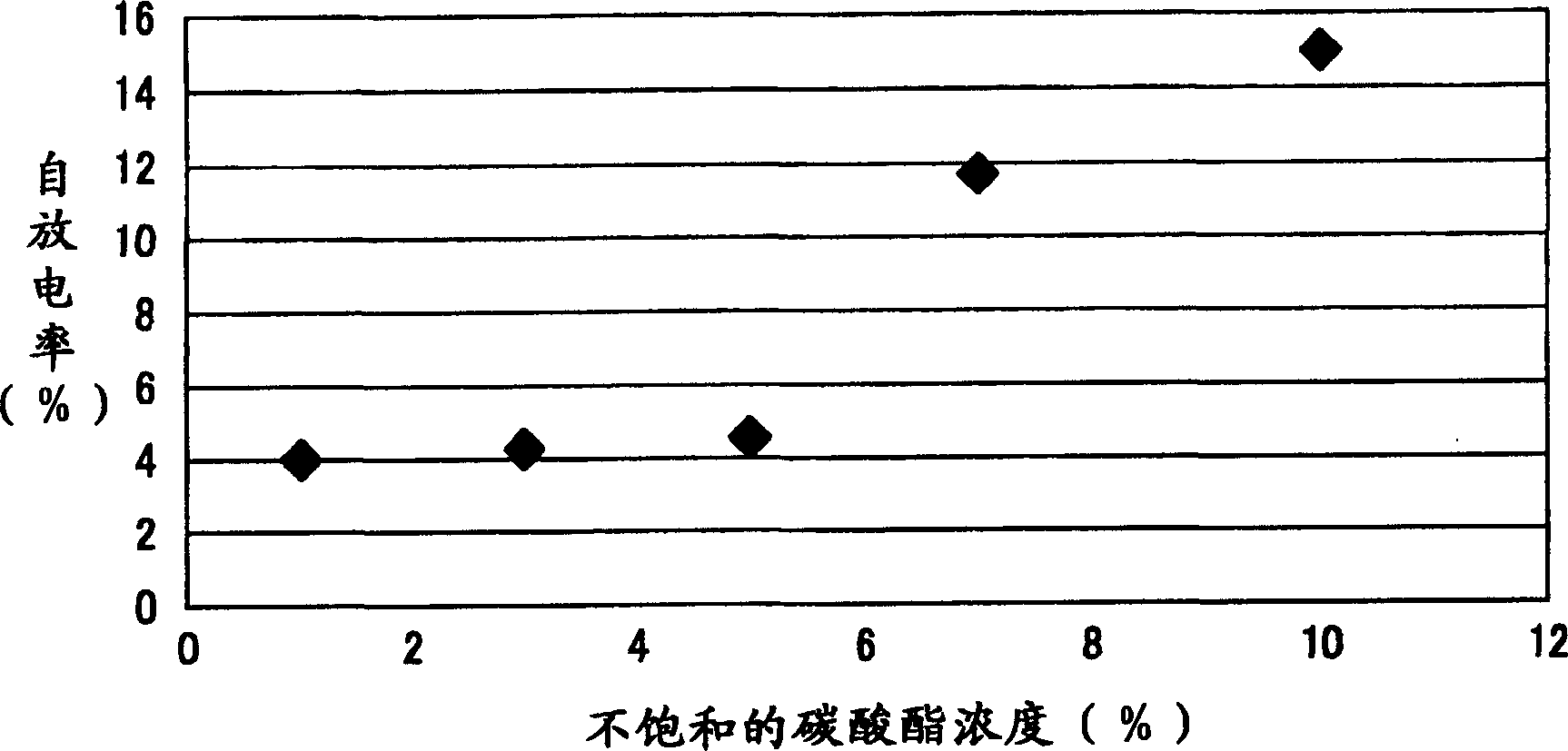

[0068] A cylindrical nonaqueous electrolyte secondary battery was manufactured in the same manner as in Example 1 except that the concentration of vinylene carbonate was 3% by volume.

example 3

[0070] A cylindrical nonaqueous electrolyte secondary battery was produced in the same manner as in Example 1 except that the concentration of vinylene carbonate was 5% by volume.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com