Method and apparatus for measuring calcium oxalate scaling

A technology of calcium oxalate and scaling, which is applied in measuring devices, testing water, testing food, etc. It can solve the problems of inapplicable test calcium oxalate solution and unable to provide the necessary conditions for calcium oxalate crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

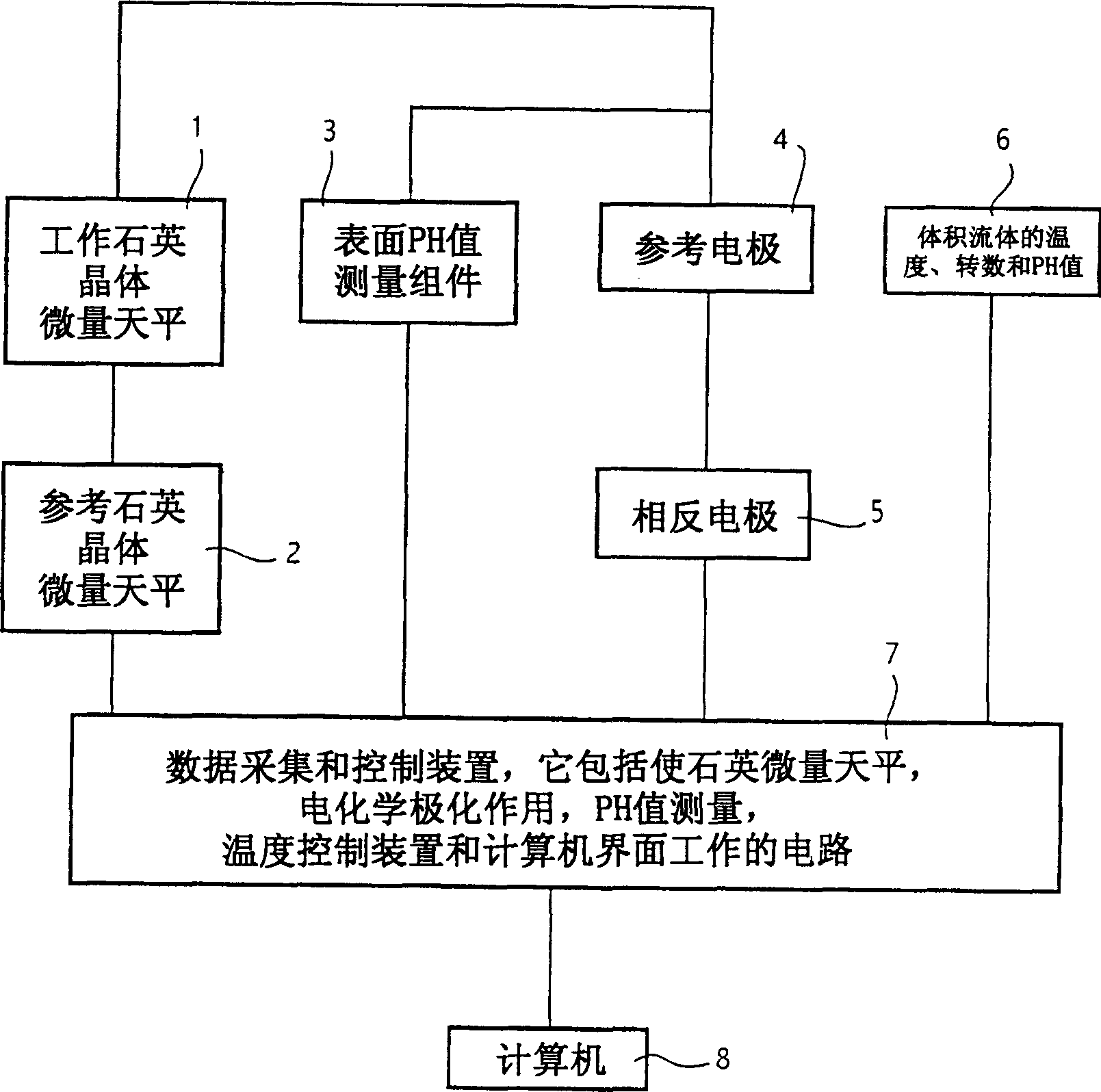

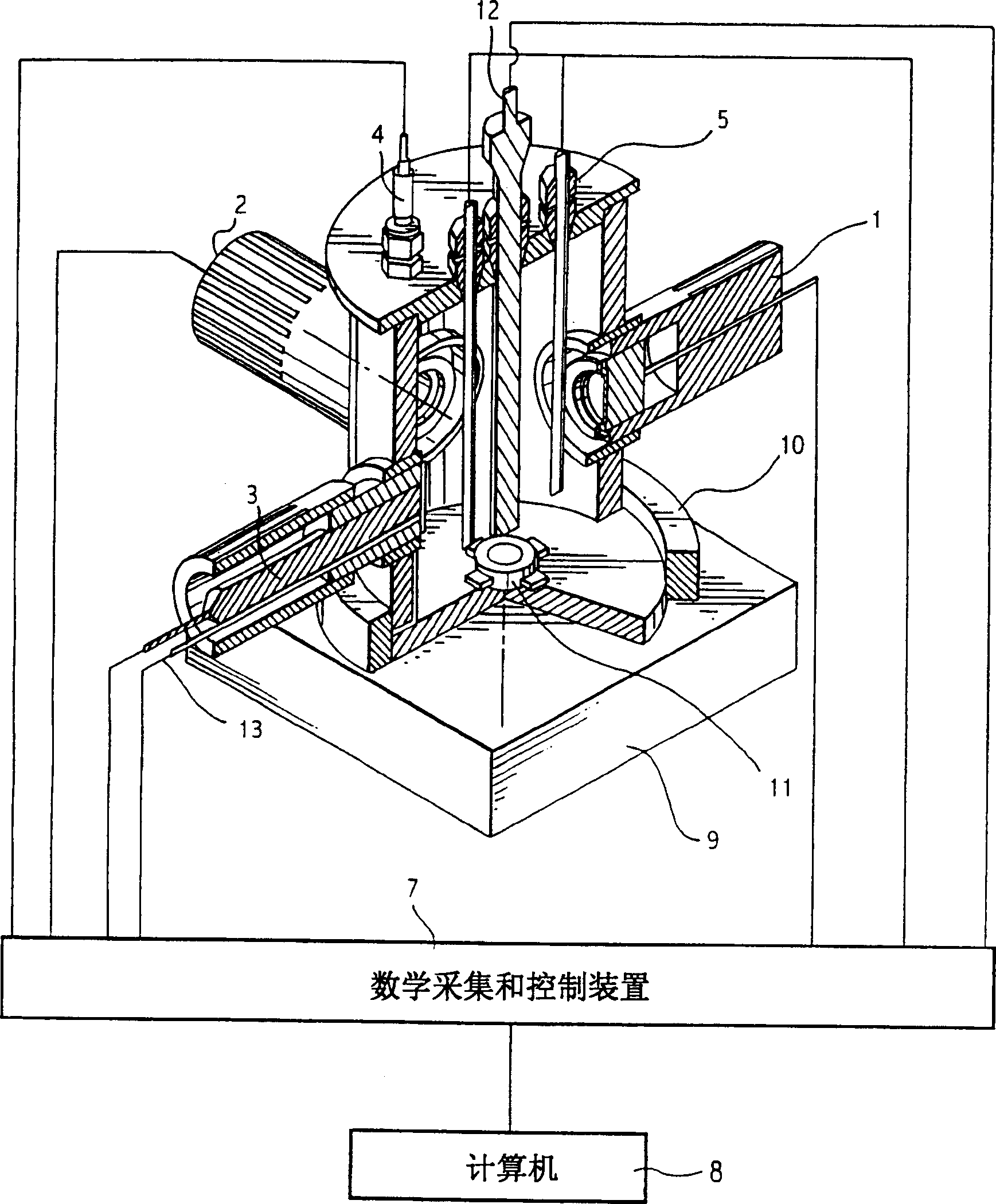

Method used

Image

Examples

example 1

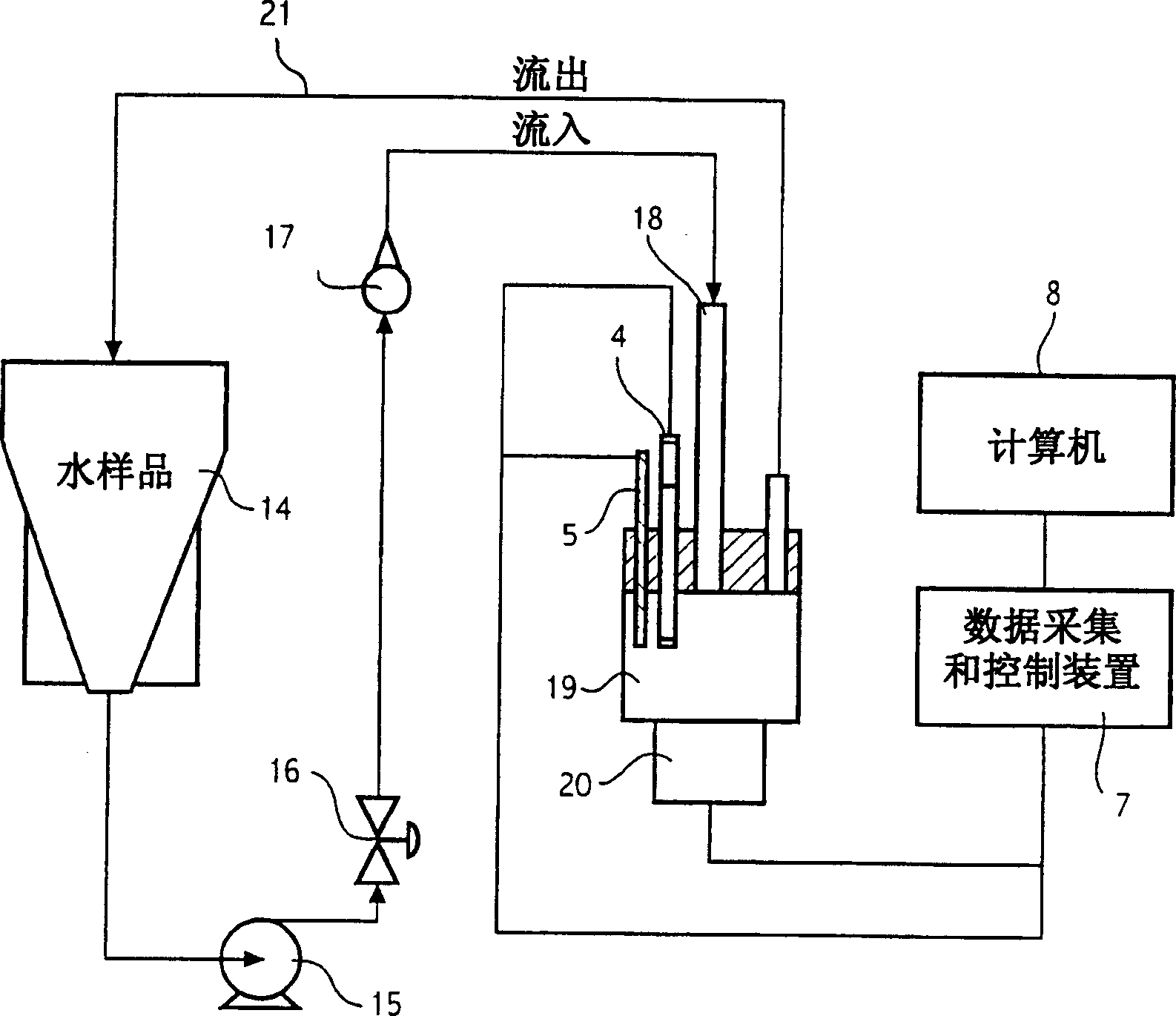

[0095] The following describes the use of the method and apparatus of the present invention to measure the effectiveness of calcium oxalate scale inhibitors in a Kraft pulp bleaching plant. The following description is only one application of the present invention and is not limiting.

[0096] Pulp produced by the Kraft process is usually bleached in a multi-stage sequence to obtain the desired gloss and strength. The main purpose of pulp bleaching is to increase the gloss of the pulp and make it suitable for printing paper and tissue grade paper by removing or reforming the lignin and poor quality products of unbleached pulp. Bleaching of chemical pulp is accomplished through a series of treatments including chlorine dioxide, aggressive hydrogen peroxide and other bleaching agents. The bleaching of chemical pulp usually begins with the use of chlorine dioxide in the first stage. Pulp bleaching is carried out through the chemical reaction of the bleaching agent with the ligni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com