Method for purifying pollutant in water by using biological activity carbon-catalysis or activated carbon and oxidation of ozone

A biological activated carbon and ozone oxidation technology, applied in the field of water treatment, can solve the problems of low ozone utilization efficiency, low organic matter removal efficiency, and high treatment cost, and achieve the effects of reducing water treatment costs, good removal effect, and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

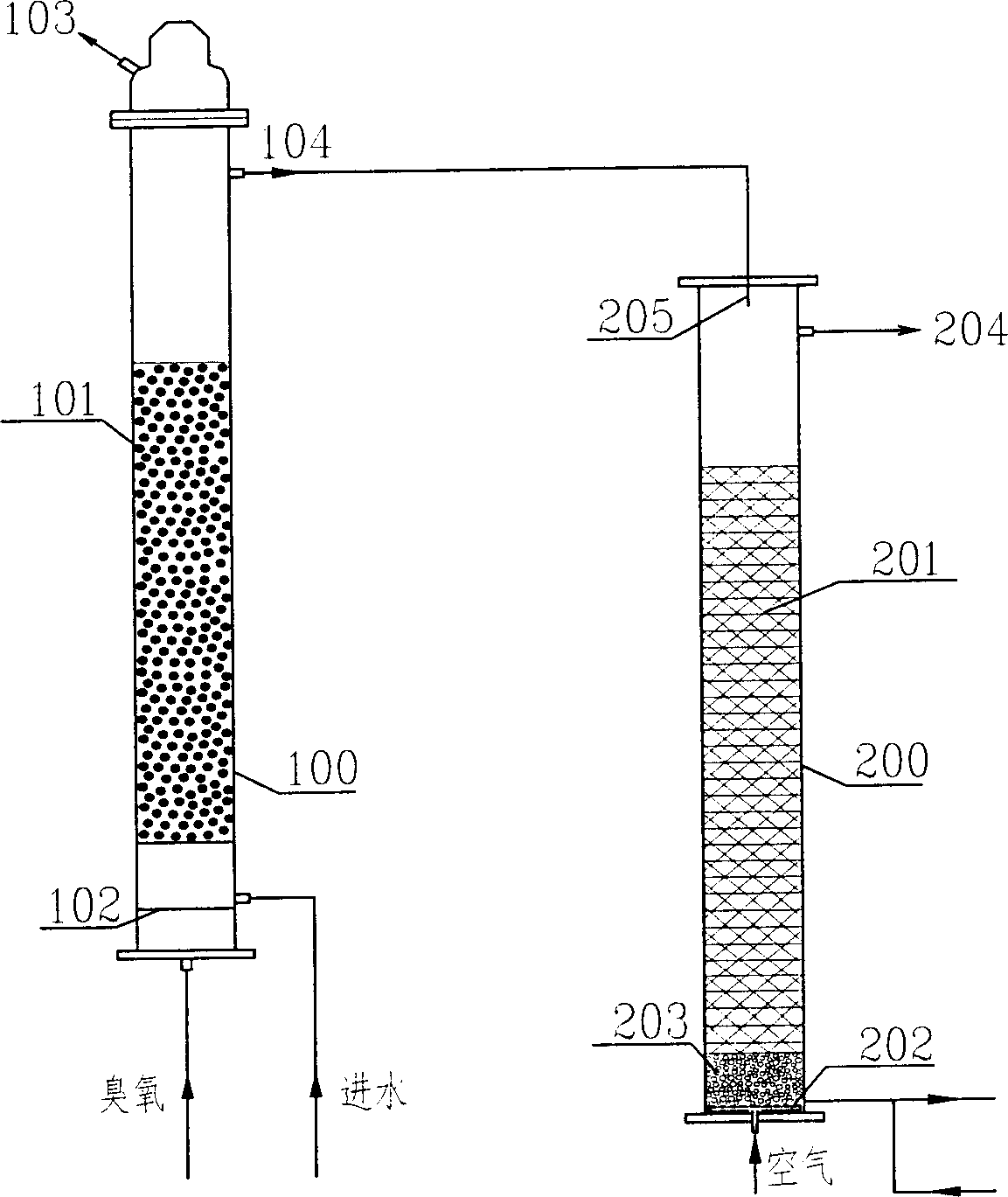

[0018] Example 1: Activated carbon catalyzed ozone oxidation of secondary effluent of urban sewage treatment plant - biological activated carbon purification.

[0019] like figure 1 As shown, the secondary effluent of the urban sewage treatment plant enters from the lower part of the activated carbon catalytic ozone oxidation reactor 100, the ozone gas is introduced from the bottom of the reactor, and the ozone gas passes through the gas distribution plate 102 in the reactor and the water. Uniform mixing; water and ozone gas flow upward through the activated carbon layer 101 filled in the reactor, the residence time is 16min, the organic pollutants in the water are removed or transformed; the water after preliminary treatment flows out from the upper water outlet 104 of the reactor , the ozone tail gas is discharged from the gas discharge port 103 of the reactor;

[0020] The above-mentioned preliminarily treated water flows in from the water inlet 205 on one side of the biol...

Embodiment 2

[0027] Example 2: Activated carbon catalytic ozone oxidation-biological activated carbon method purifies reservoir water containing trace organics.

[0028] Adopt activated carbon catalyzed ozone oxidation-biological activated carbon method to purify reservoir water, and its steps are roughly the same as Example 1, wherein the residence time of the reservoir water to be treated in the activated carbon catalytic ozone oxidation unit is 16min, and the residence time in the biological activated carbon unit is 15min. In the activated carbon catalytic ozone oxidation unit, different doses of ozone can be added according to the treatment target. When the dosage of ozone is 3mg / L, the removal effect of pollutants in water is shown in Table 2.

[0029] The removal rate of total organic carbon (TOC) in water by ozone oxidation-biological activated carbon method was 32.9%, and the TOC removal rate of activated carbon catalytic ozone oxidation-biological activated carbon method was 36.9%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com