Dual wavelength sensitive photopolymer holographic recording material and preparation method thereof

A holographic recording material, photopolymer technology, applied in photosensitive materials, optics, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: according to the concrete preparation process of material of the present invention is as follows:

[0026] 1. Weigh each raw material by weight percentage;

[0027] 2. Dissolve polyvinyl alcohol (PVA, with a molecular weight of about 1750 g / mol) in distilled water and heat to 80°C, stir to dissolve it, and finally obtain a 10wt% PVA solution;

[0028] 3. Dissolve triethanolamine (TEA) in distilled water, fully dissolve, and then add to the PVA solution;

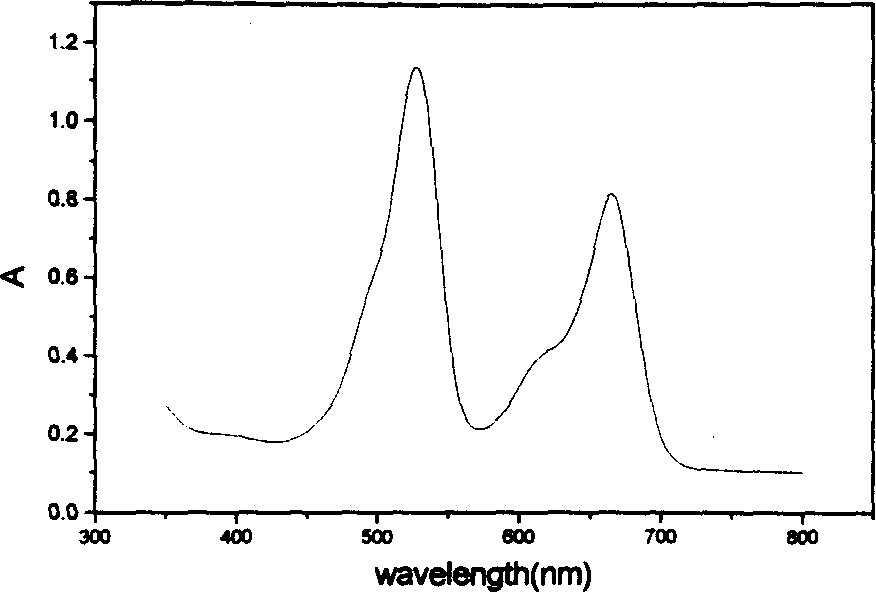

[0029] 4. Fully dissolve the erythrosine (ErB) body in distilled water to obtain an ideal dye solution, then add the dye solution to the PVA solution obtained in step 3 and fully stir to dissolve it completely;

[0030] 5. Dissolve the methylene blue crystal (MB) in distilled water separately to obtain the ideal dye solution, then add the dye solution into the PVA solution obtained in step 4 and stir fully to dissolve it completely;

[0031] 6. Finally, add acrylamide (AA) monomer and methylene bisacryl...

Embodiment 2

[0041] Embodiment 2: according to above-mentioned specific process preparation material, finally obtain photopolymer dry film component to be:

[0042] Polyvinyl alcohol: 40wt%

[0043] Acrylamide: 18wt%

[0044] Methylenebisacrylamide: 4wt%

[0045] Triethanolamine: 27.4wt%

[0046] Erythrosine: 0.12wt%

[0047] Methylene blue: 0.23wt%

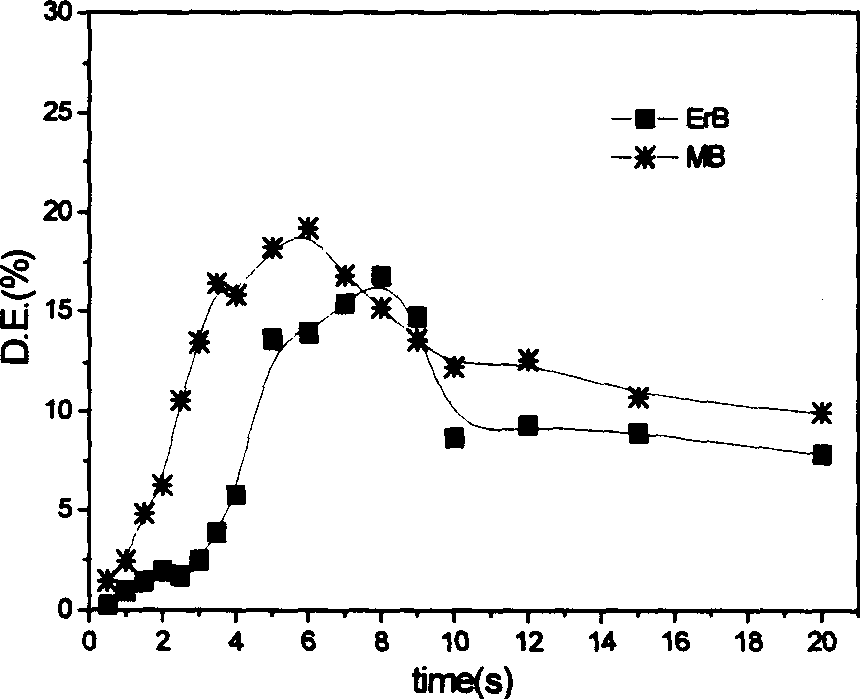

[0048] Expose the material with Ar+ laser and He-Ne laser respectively, and the obtained diffraction efficiency growth curve is as follows figure 2 , the diffraction efficiencies of red light and green light are 17% and 16% respectively

Embodiment 3

[0049] Embodiment 3: prepare material according to above-mentioned specific process, finally obtain photopolymer dry film component to be:

[0050] Polyvinyl alcohol: 60wt%

[0051] Acrylamide: 12.6wt%

[0052] Methylenebisacrylamide: 4.3t%

[0053] Triethanolamine: 25wt%

[0054] Erythrosine: 0.21wt%

[0055] Methylene blue: 0.27wt%

[0056] The diffraction efficiencies of red light and green light are 30%, 20% respectively

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com