Vapour deposition device for metal organic compound

An organic compound and vapor phase deposition technology, which is applied in metal material coating process, gaseous chemical plating, chemical instruments and methods, etc., can solve the problem of growth, high maintenance cost, unadjustable flow state, and inability to reach a better layer To achieve the effect of excellent surface morphology and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

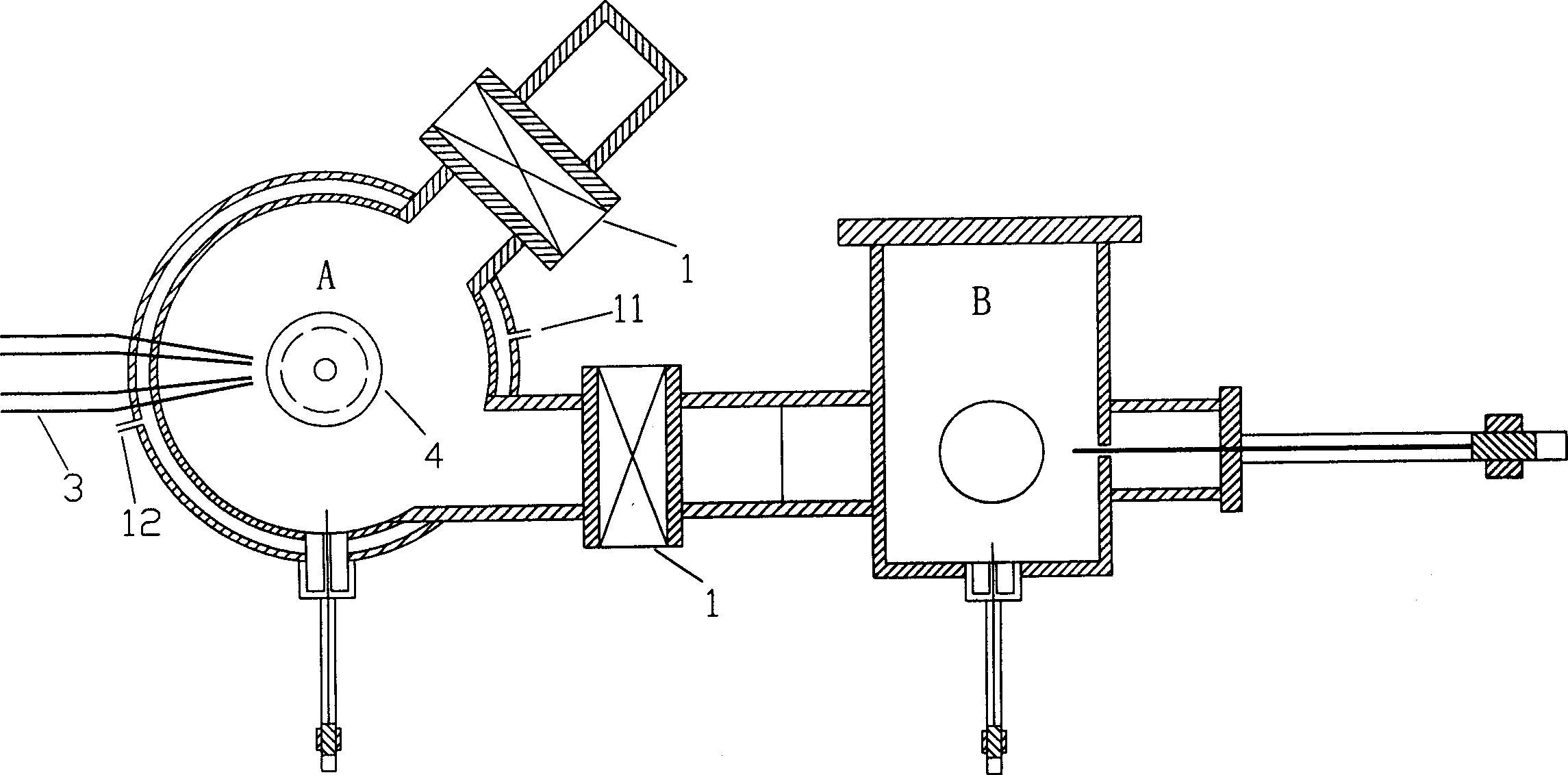

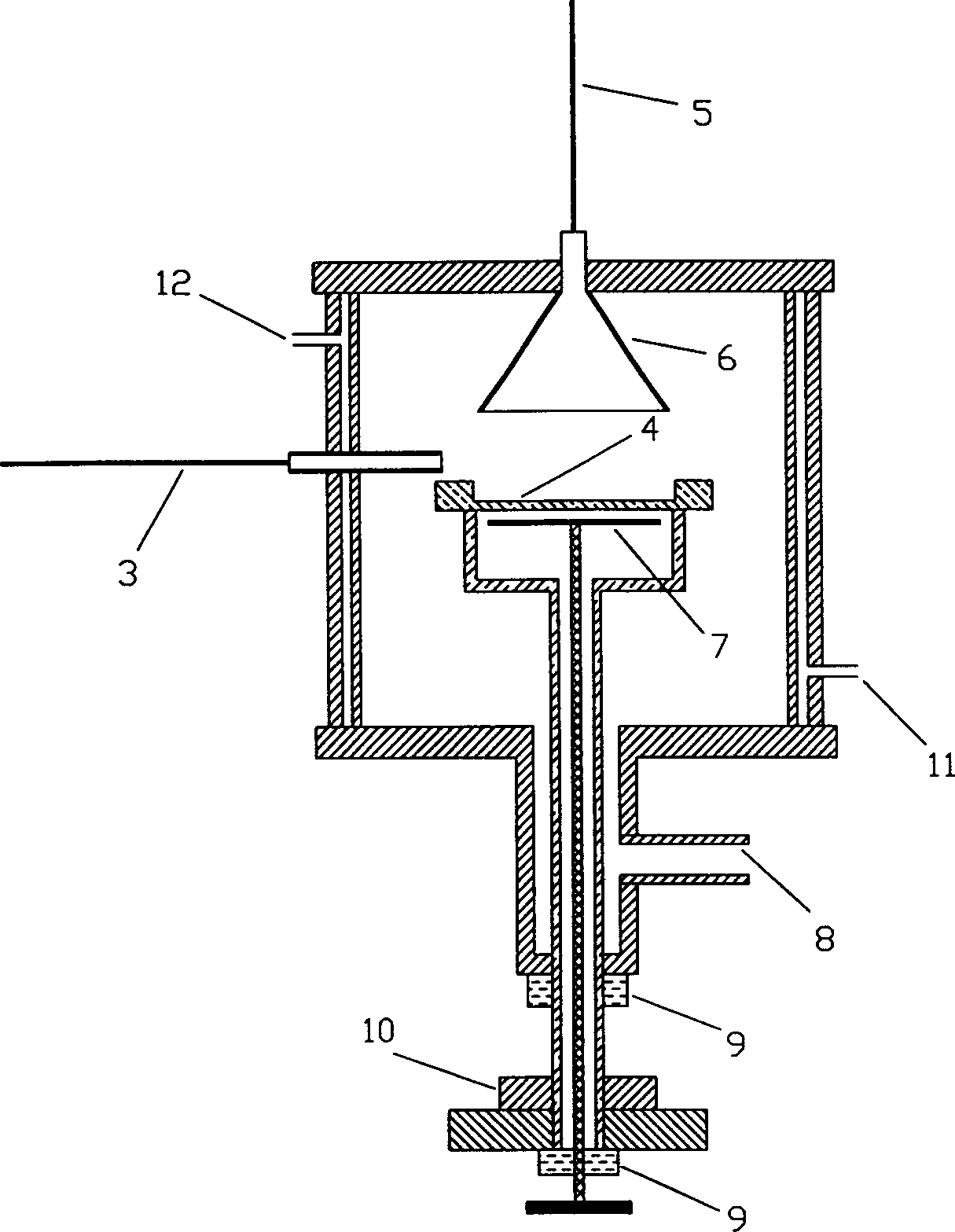

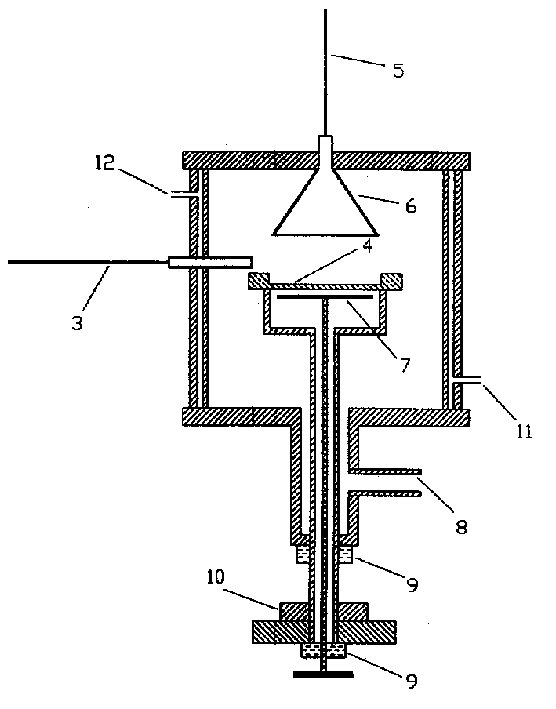

[0008] refer to figure 1 , figure 2 , the metal organic compound vapor deposition device of the present invention comprises a growth chamber A communicated with a gate valve 1 and a sampling chamber B, a horizontal sample tray 4 driven by a motor 10 to rotate is installed in the growth chamber A, and the sample tray 4 There is a graphite heater 7 below, 8 in the figure is the tail gas extraction port, 9 is a magnetic fluid sealing device, and the auxiliary gas pipeline 5 for transporting nitrogen and hydrogen (non-reactive gas) is arranged on the top of the growth chamber, and the auxiliary gas pipeline 5 is vertical A cone-shaped quartz cover 6 is connected to the gas outlet of the sample tray 4, so as to realize the adjustment of the gas flow pattern on the sample surface and ensure sufficient reaction of the reaction gas on the substrate surface. The side wall of the growth chamber is provided with a horizontal main gas pipeline 3 for conveying the reaction gas. In order ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com