Direct connection pressure separating system for heat supply and iar conditioner

A separation system, direct connection technology, applied in heating systems, hot water central heating systems, household heating, etc., can solve problems such as reducing the overall advantages of the system, reducing thermal efficiency, affecting system operation, etc., to avoid serious corrosion of pipelines , the effect of increasing the cost and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

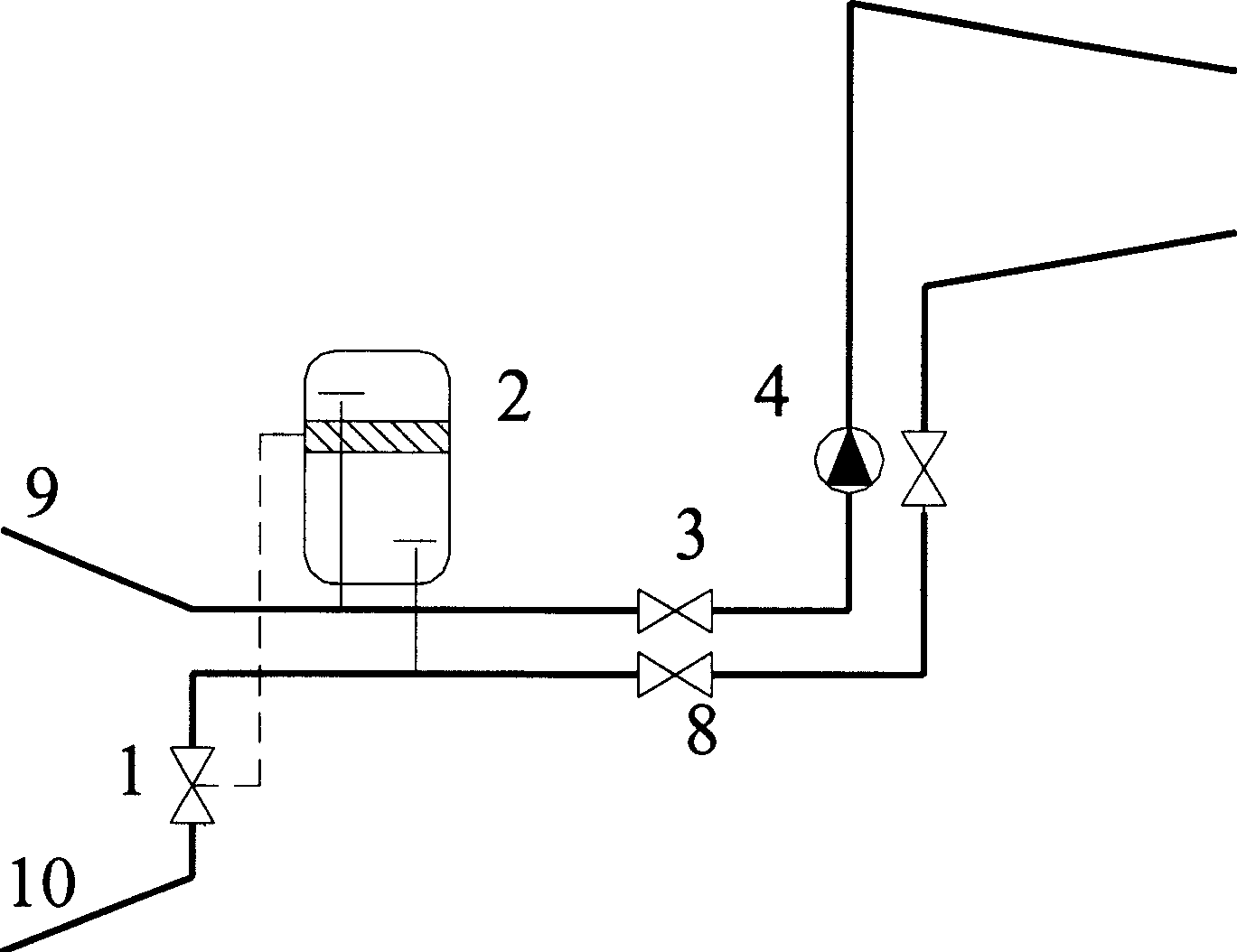

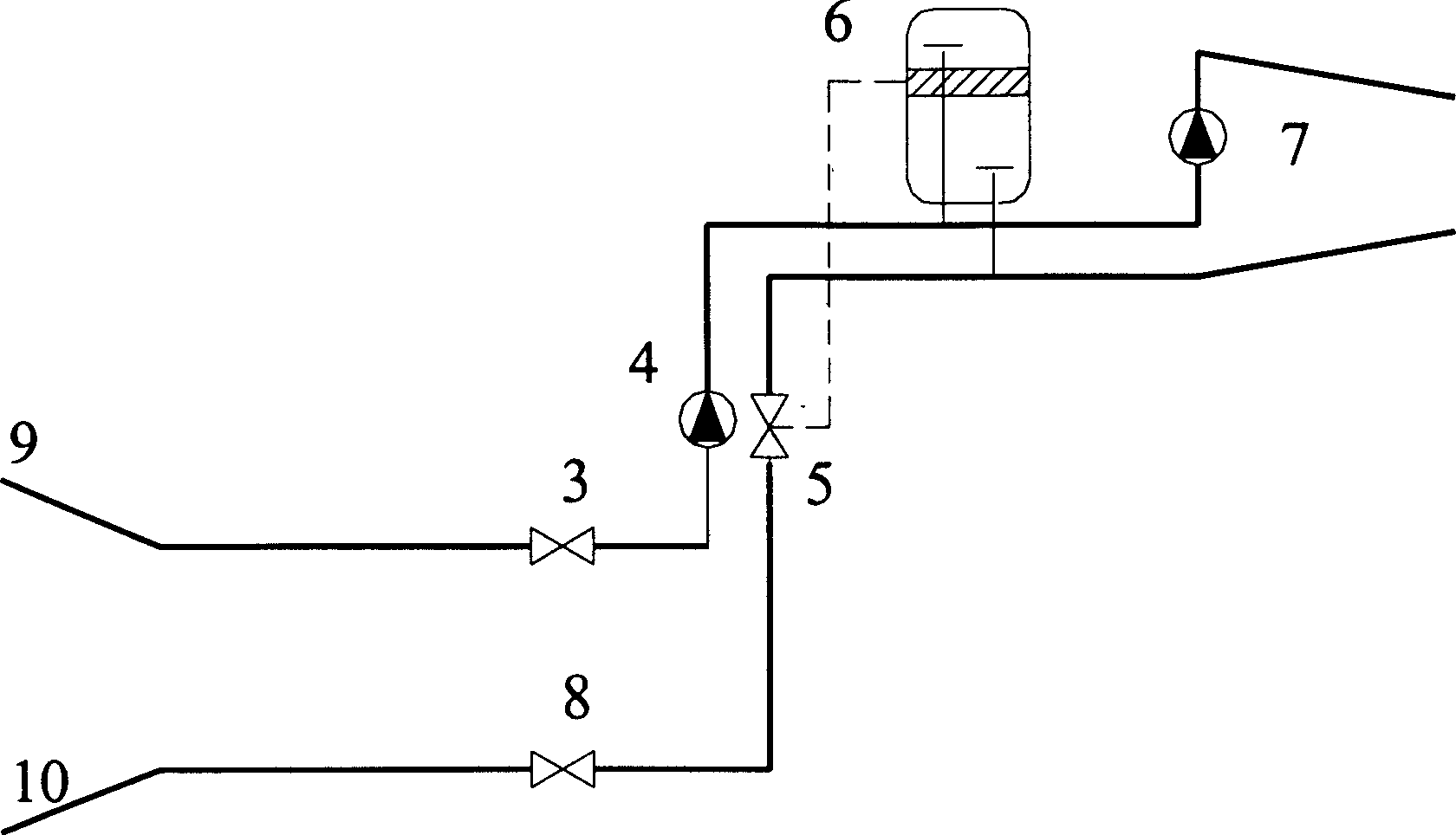

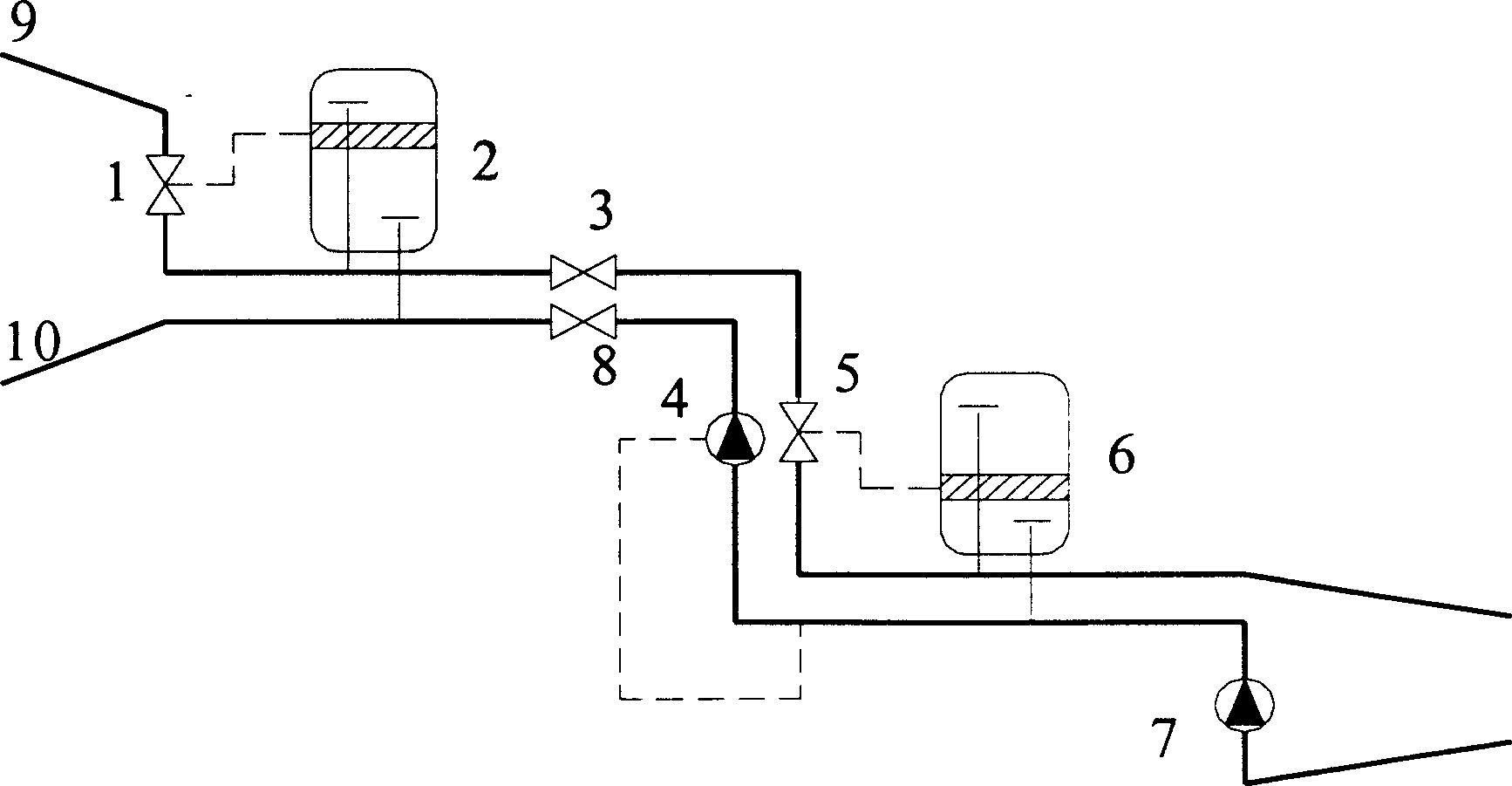

[0041]In terms of system design, the present invention includes: shut-off valve V1, control tank A2, fast shut-off valve AVm3 interlocked with booster pump P4 installed on water supply pipe 9, shut-off valve V5, control tank B6, shut-off valve V7, partial system circulation pump P7, shut-off valve V9, shut-off valve V10, shut-off valve V8, control tank B6 temperature gradient control valve RVm5, shut-off valve V6, installed on the return pipe 10 and interlocked with the booster pump P4 The electromagnetic valve AVn8, the spring safety valve V15, the control tank A2 temperature gradient control valve RVn1, and the shut-off valve V2. The water supply of the system enters the local system from the water supply pipe through the shut-off valve V1, and is sequentially connected to the control tank A2 connected in parallel with the water supply pipe, the shut-off valve AVm3 interlocked with the booster pump P4, the shut-off valve V5, the booster pump P4, and the The water supply pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com