Structure of LED electrode and producing method

A manufacturing method and electrode technology, applied to circuits, electrical components, semiconductor devices, etc., can solve problems such as reduced lifespan, damaged junctions, and opacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The content of the present invention can be disclosed through the following embodiments in conjunction with the relevant drawings. The color and material of the LED used in the present invention and the structure of the light-emitting diode are not limited, as long as the light-emitting diode that can emit light is applicable. The electrode structure of the present invention is suitable for lamination packaging of light-emitting diodes of different colors, so as to obtain light of another color or white light by mixing light of two colors or three colors.

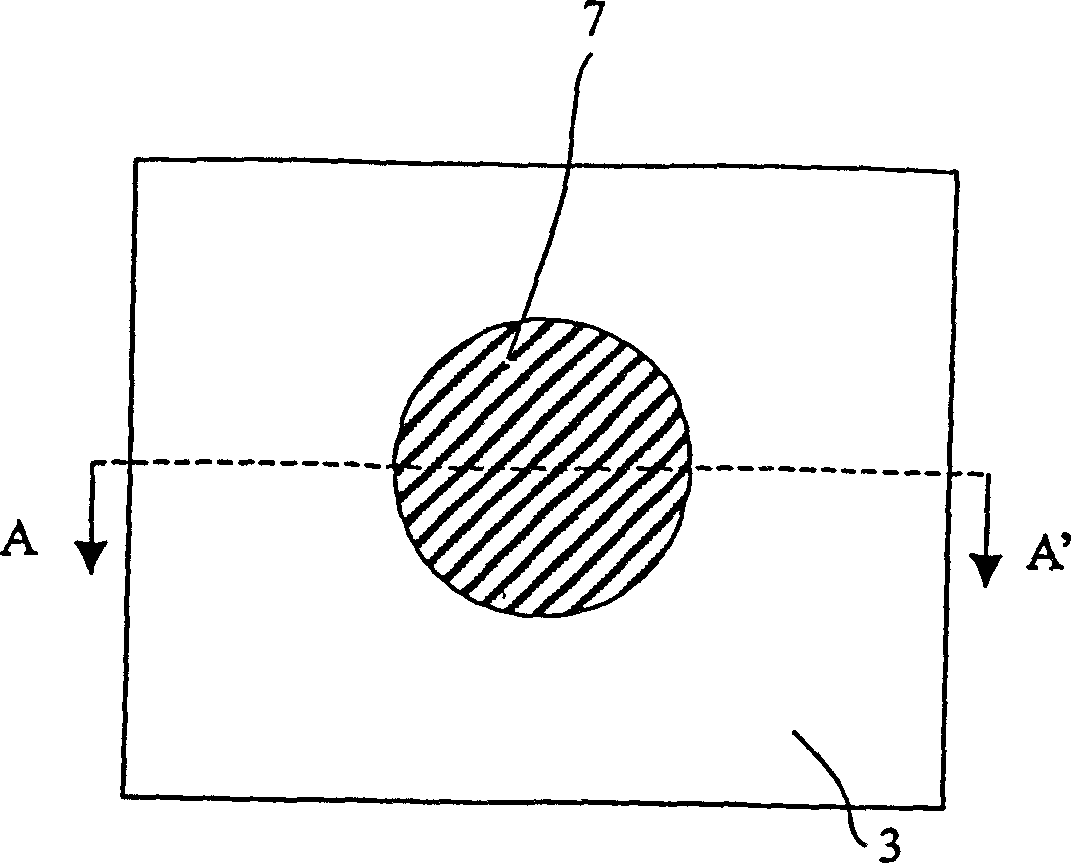

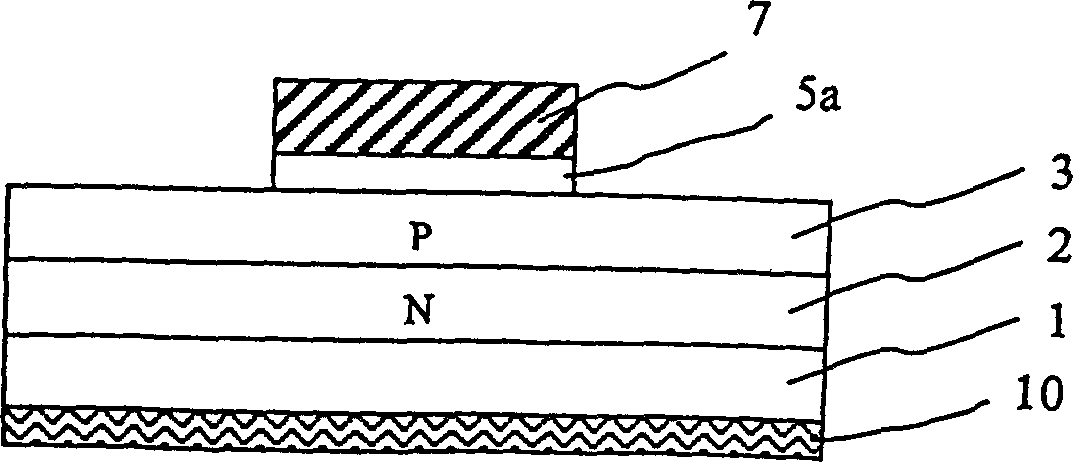

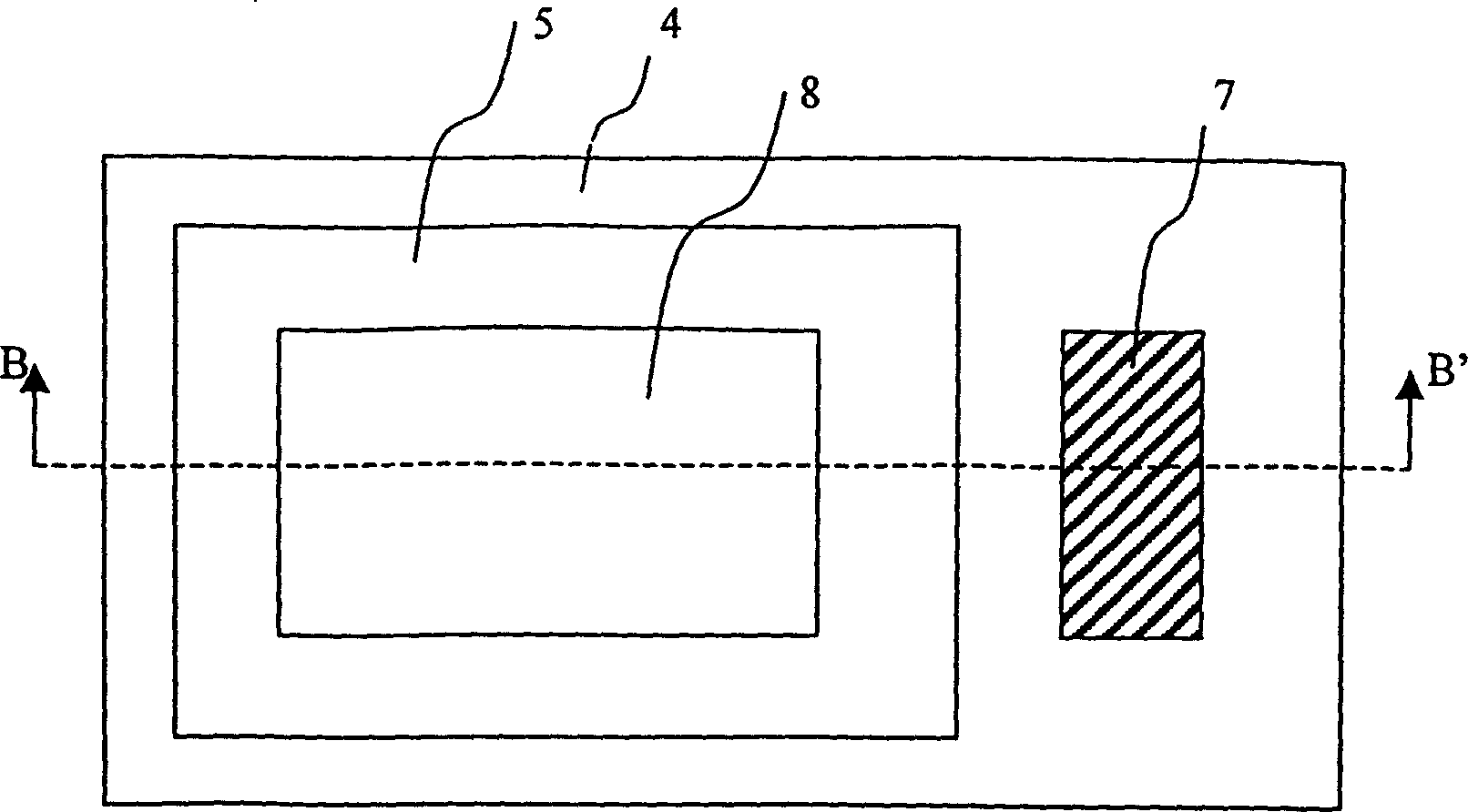

[0032] figure 2 A plan view showing a first embodiment of the electrode configuration of the present invention for the lowermost LED of the stack package. image 3 along figure 2 Sectional view of line BB'. The substrate 1 is generally an opaque group III-V or II-VI compound semiconductor such as GaAS, GaP or GaN. On substrate 1, one layer of n-type semiconductor layer 2 is epitaxy by epitaxy technology (see ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com