Method and apparatus for gaseous fuel injection into IC engine and controlling combustion

A gaseous fuel and internal combustion engine technology, applied in the direction of fuel injection control, gaseous engine fuel, and adding non-fuel substances to fuel, etc., can solve the problems of lean mixture of fuel and air, reduced engine cycle efficiency, and inability to support premixed combustion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

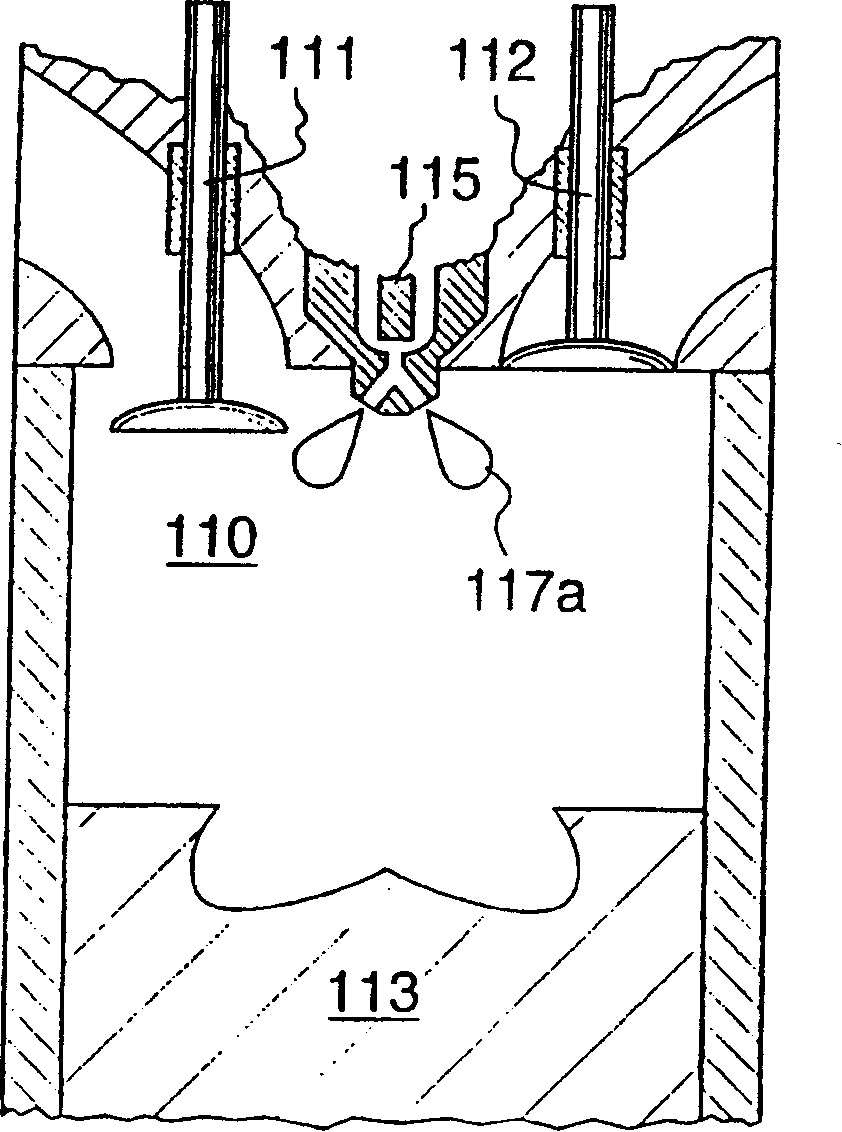

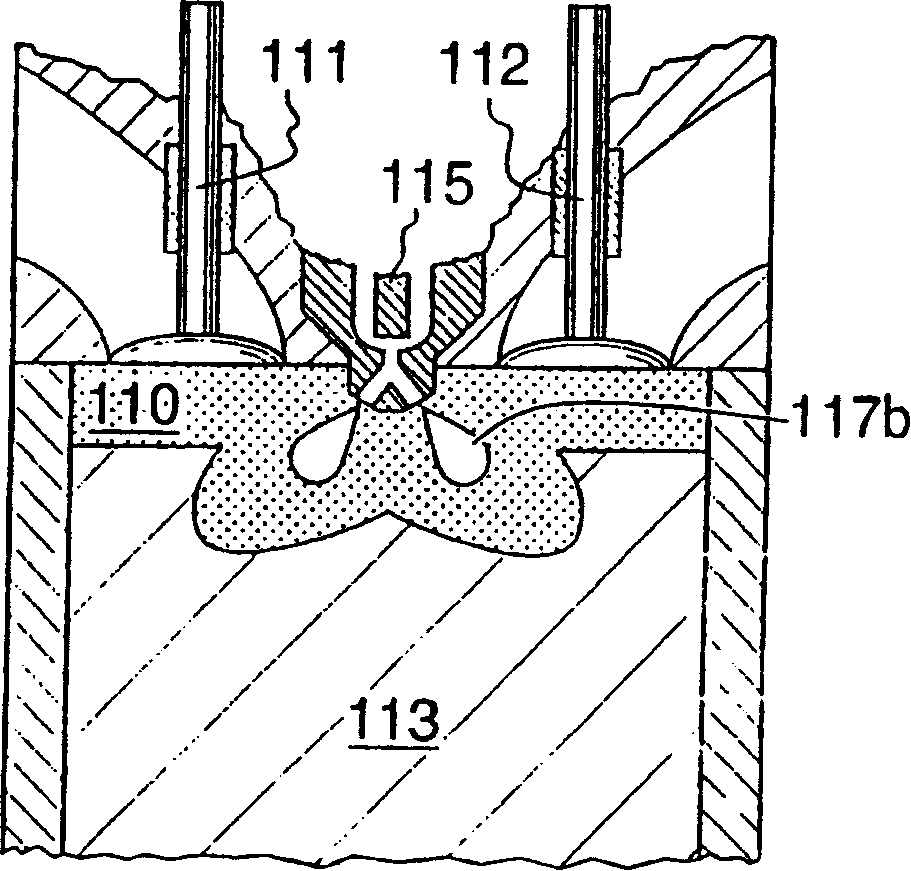

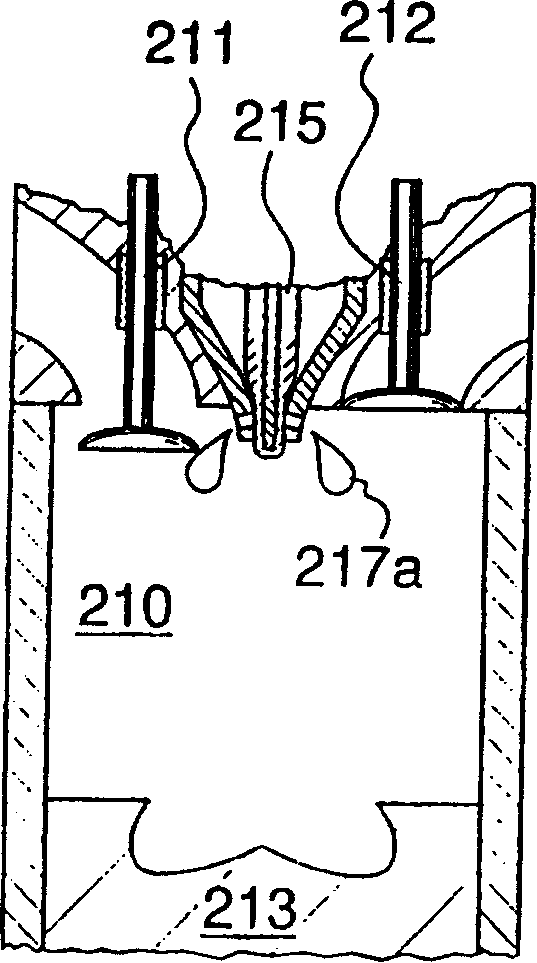

[0048] In a preferred method, fuel is injected into cylinders of a four-stroke internal combustion engine having at least one reciprocating piston and a crankshaft connected to the piston. In this disclosure, the piston position within the cylinder is described with reference to crankshaft angles before or after top dead center (TDC). When the piston reaches the end of its upward stroke and is about to begin its downward stroke (ie, the point at which the piston is closest to the cylinder head), the piston is at TDC.

[0049] The method involves a primary fuel, preferably a gaseous fuel such as natural gas, propane, biogas, methane, or hydrogen. The method may also include controlling the timing of combustion of the primary gas with the ignition source. The ignition source may be, for example, a pilot fuel which is more prone to spontaneous combustion than the primary fuel, a hot surface ignition source such as a glow plug, a spark plug, or other known ignition means. When a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com