Low energy consumption technique for thermally cracking biomass and deices

A technology of biomass pyrolysis and low energy consumption, which is applied in the preparation of liquid hydrocarbon mixtures and the petroleum industry to achieve the effects of energy saving, uniform mixing and increased production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

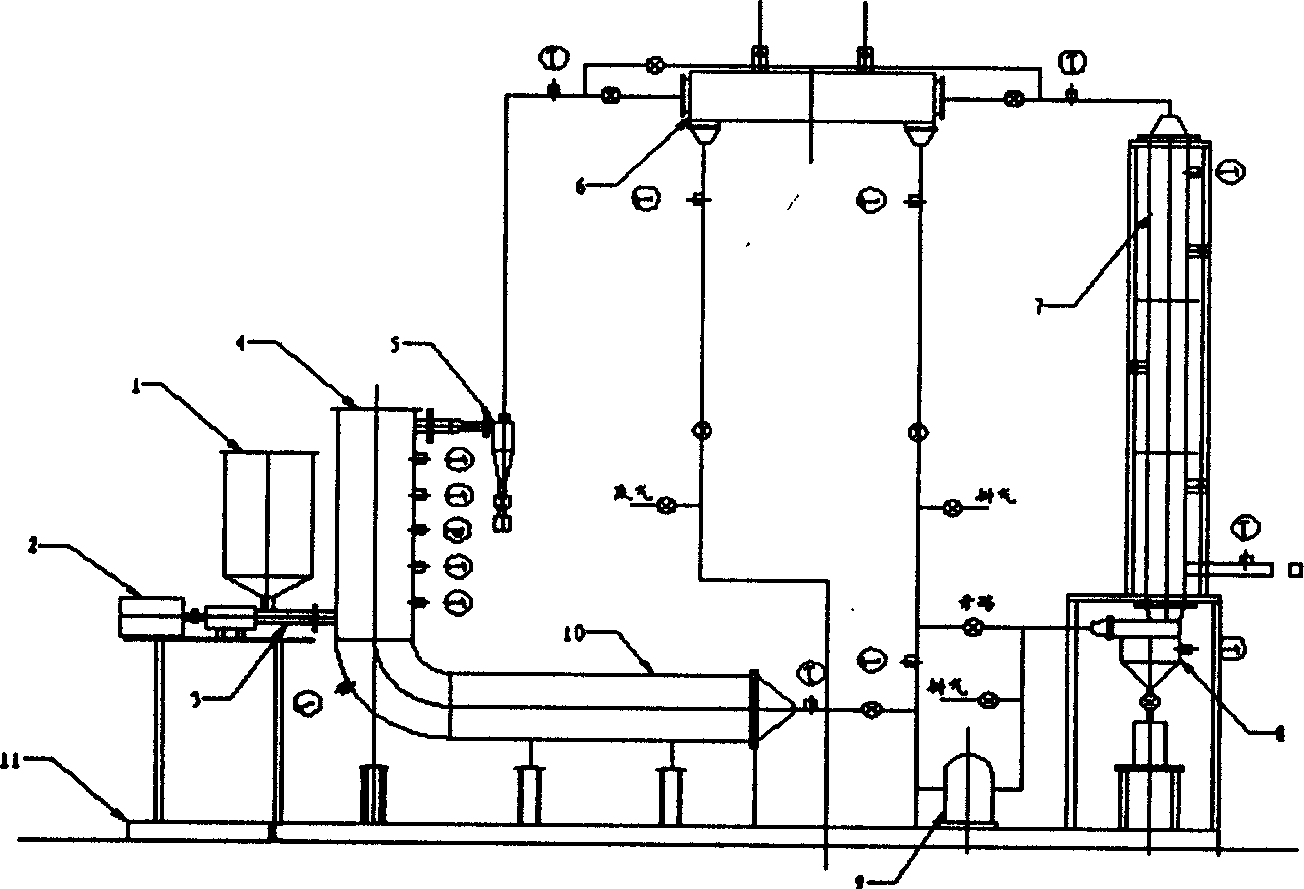

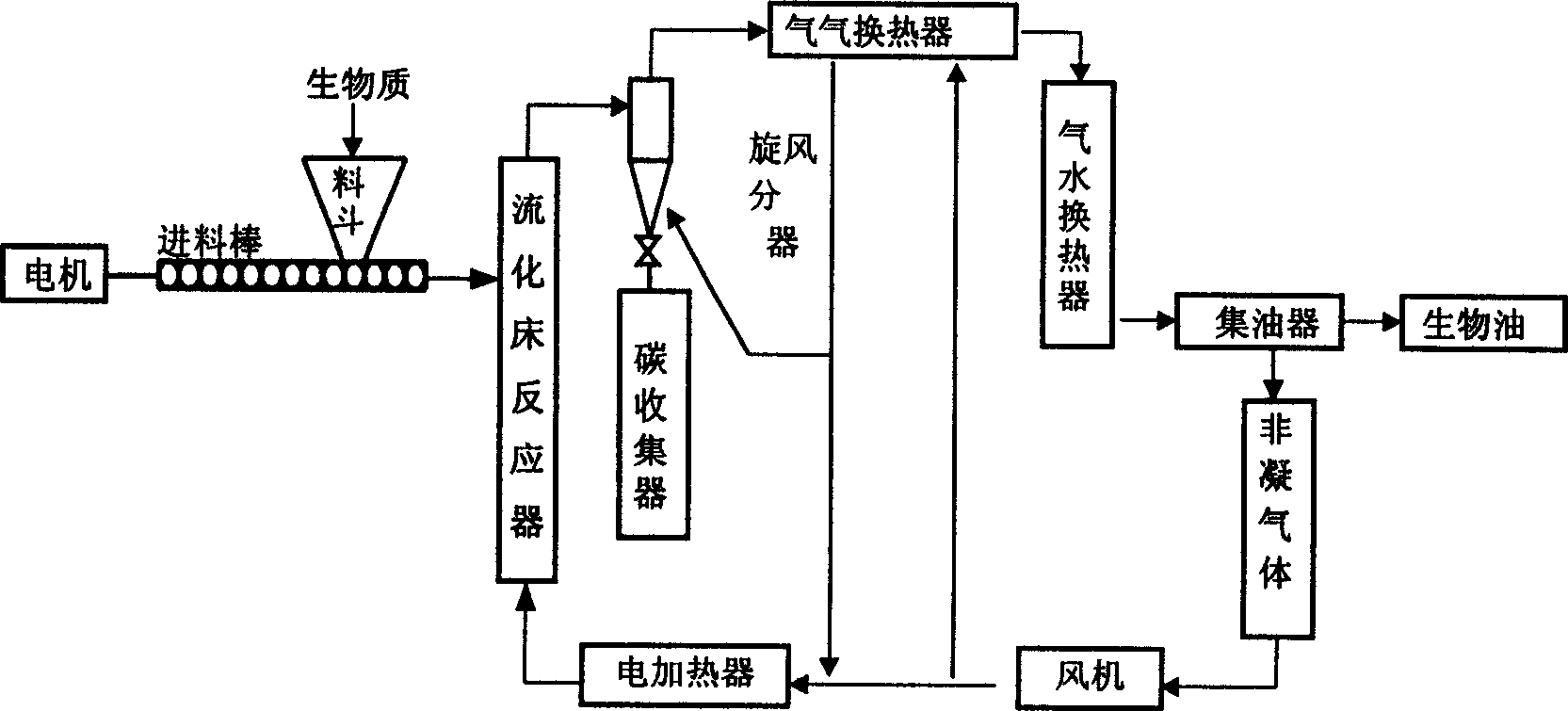

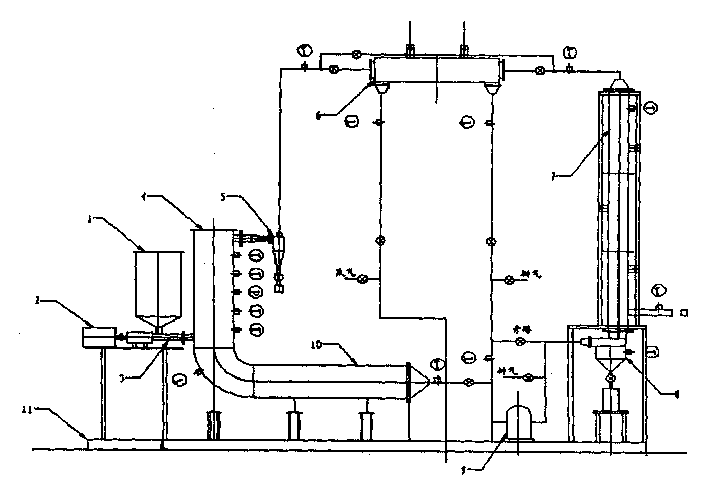

[0017] Depend on figure 2 Shown, the technological process of the present invention is: 1, biomass is sent into fluidized bed reactor continuously by the feeder that frequency modulation motor, feed rod, hopper are formed, and reactor is the key equipment in the whole device, must make sawdust It can be heated evenly in a very short time, and can achieve a high heating rate (greater than 1000 ° C / s) and a limited residence time; 2. The Roots blower installed in the middle sends high-temperature nitrogen into the quartz sand as the intermediate carrier. Biomass gasification under the action of high-temperature gas and high-temperature quartz sand; 3. The gasified biomass enters the cyclone separator for separation, part of the carbon particles are separated and enter the carbon collector, and the gas enters the gas-gas exchanger to make the biomass The material gas is cooled, and the gas-gas exchanger is to save heating energy; 4. After the gas-gas heat exchange, the gas at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com