Anode support tube type solid oxide fuel battery

A solid oxide and anode support technology, applied in solid electrolyte fuel cells, fuel cells, circuits, etc., can solve the problems of high cost, increased battery power density, low space utilization efficiency, etc., to increase the electrode reaction area, Effects of improving body power density and simplifying auxiliary systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

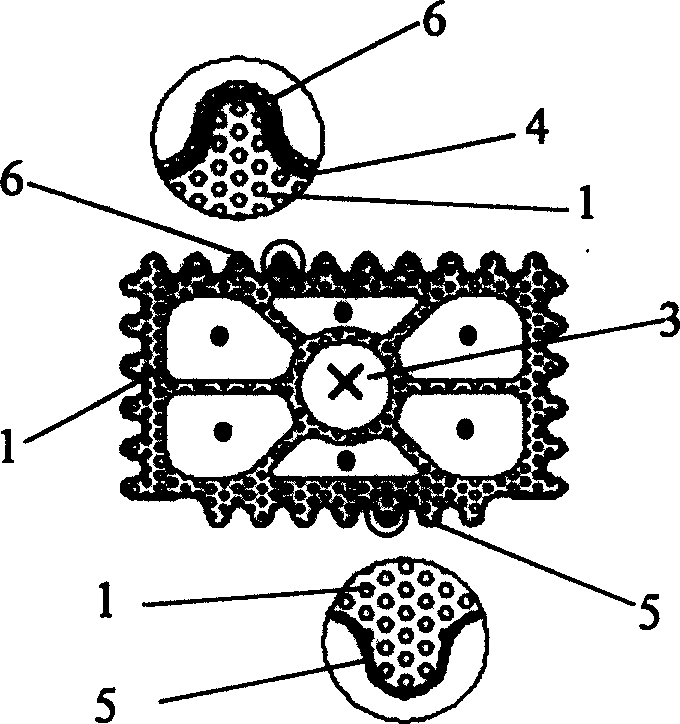

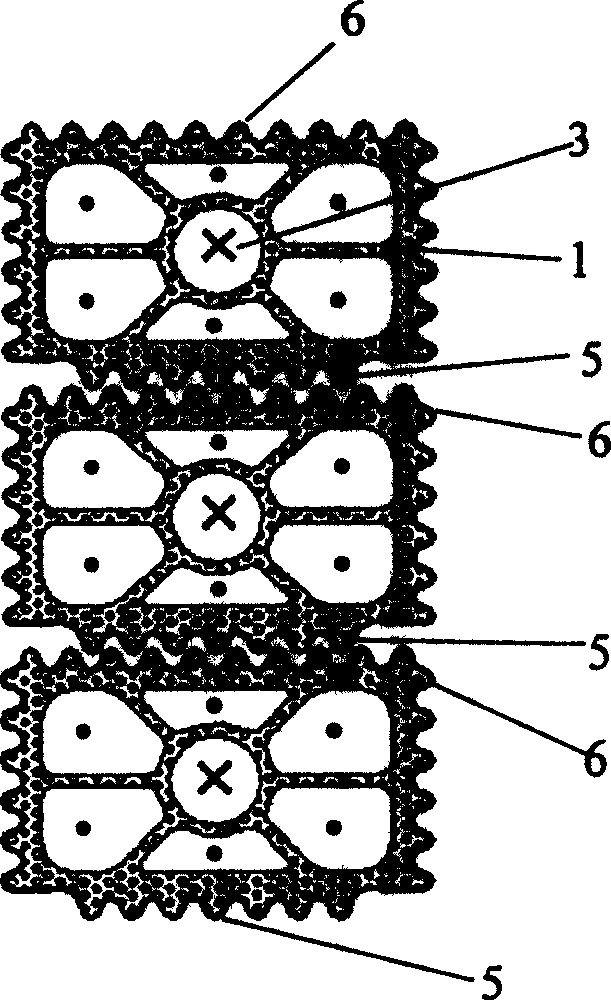

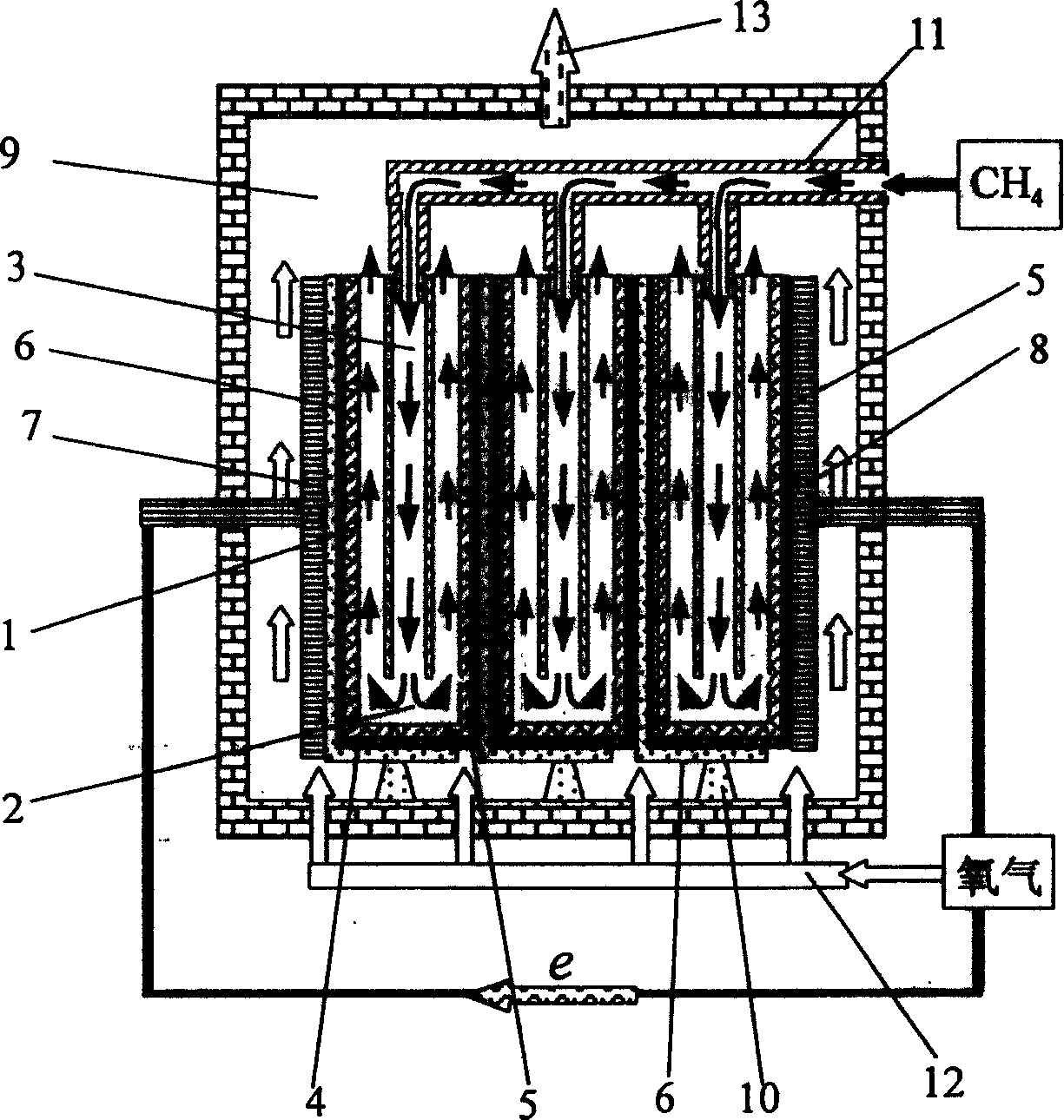

[0017] This embodiment is a tubular solid oxide fuel single cell with seven branch tubes in the inner layer tube 1 of the anode support. The anode material is Ni-YSZ cermet, the electrolyte is YSZ, and the cathode material is La 0.65 Sr 0.3 MnO 3-δ , the electrical connection material is La 0.8 Sr 0.2 CrO 3 . The production process is as follows:

[0018] Vacuum mud refining technology is adopted, cellulose (MC) is used as a bonding agent, and 60wt% NiO+YSZ ceramic mixed mud is mixed, and the upper part of the anode support inner layer tube 1 green body is formed by an extruder, and there are seven There are 6 branch pipes symmetrically distributed around the central branch pipe 3, the length of which is 600mm, the thickness of the partition wall between each branch pipe is ~0.8mm, the inner diameter of the central branch pipe 3 is 4mm, and the outer wall is composed of convex semicircular edges and concave The semicircular grooves are connected alternately and tangentia...

Embodiment 2

[0045] This embodiment is a tubular solid oxide fuel cell with three branch pipes in the inner layer tube 1 of the anode support. The grooves and ribs on the outer surface of the inner layer tube 1 have an equilateral triangle cross section, and the height of the triangle is 1 mm. The anode material is Fe-Al 2 o 3 Cermet, the electrolyte is YSZ, the cathode material is La 0.65 Sr 0.3 MnO 3-δ , the electrical connection material is La 0.8 Sr 0.2 CrO 3 ; The nominal section of the anode support inner layer tube 1 is oblate, and the inner diameter of the central branch tube 3 is 5 mm; the effective length of the battery reaction surface is 50 cm. The specific manufacturing process is the same as in Example 1 (so it is omitted). After the single cell is prepared, use 3mol / l Ni (NO 3 ) 2 aqueous solution, Ni(NO 3 ) 2 Immerse the inner wall of each branch of the inner tube 1. Before the operation of the battery stack, Ni(NO 3 ) 2 Decompose to obtain NiO, then pass fuel g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com