Method for preparing red-light rare-earth organic complex electroluminescent material and device

A rare-earth organic and luminescent technology, applied in the direction of luminescent materials, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

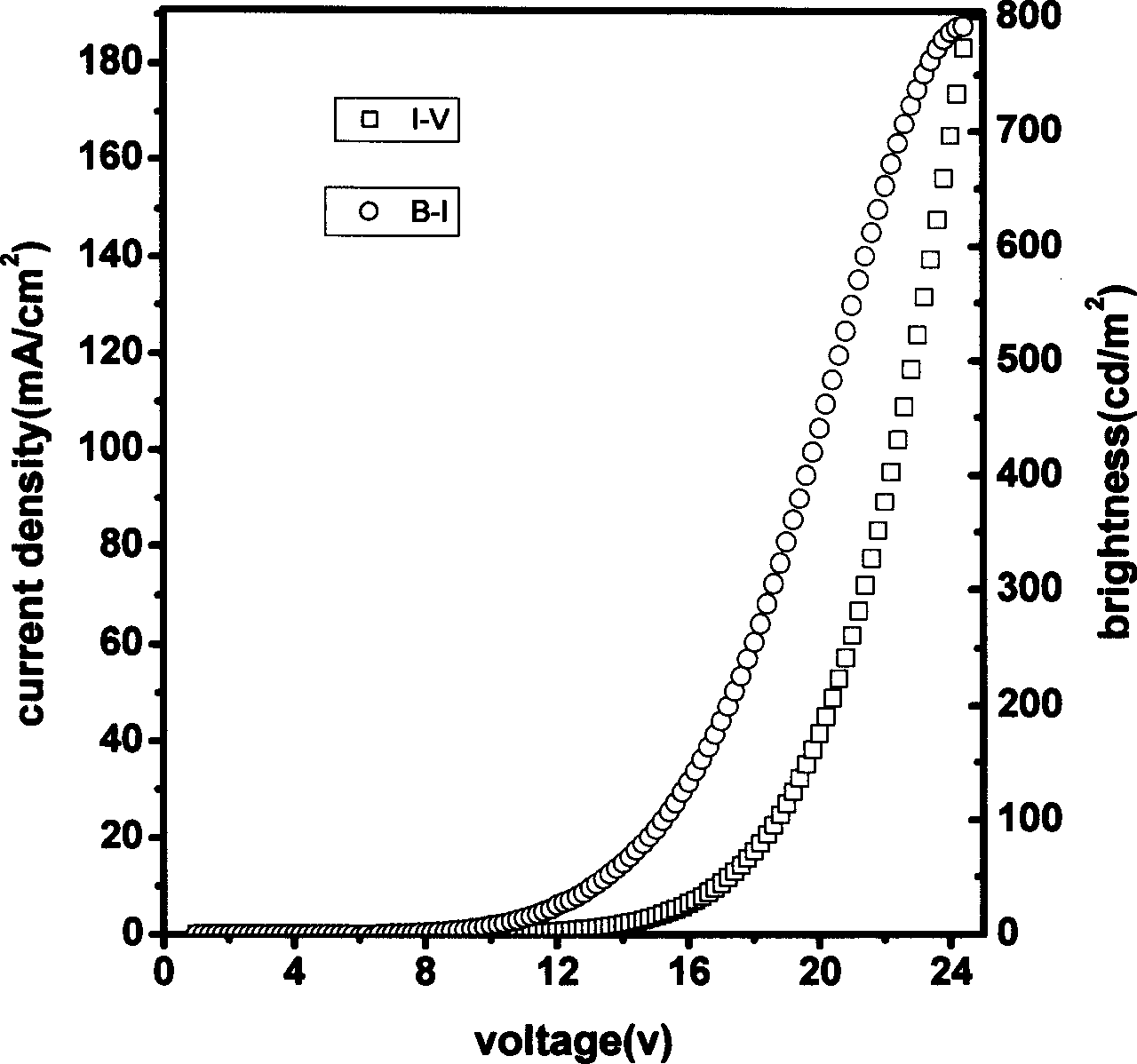

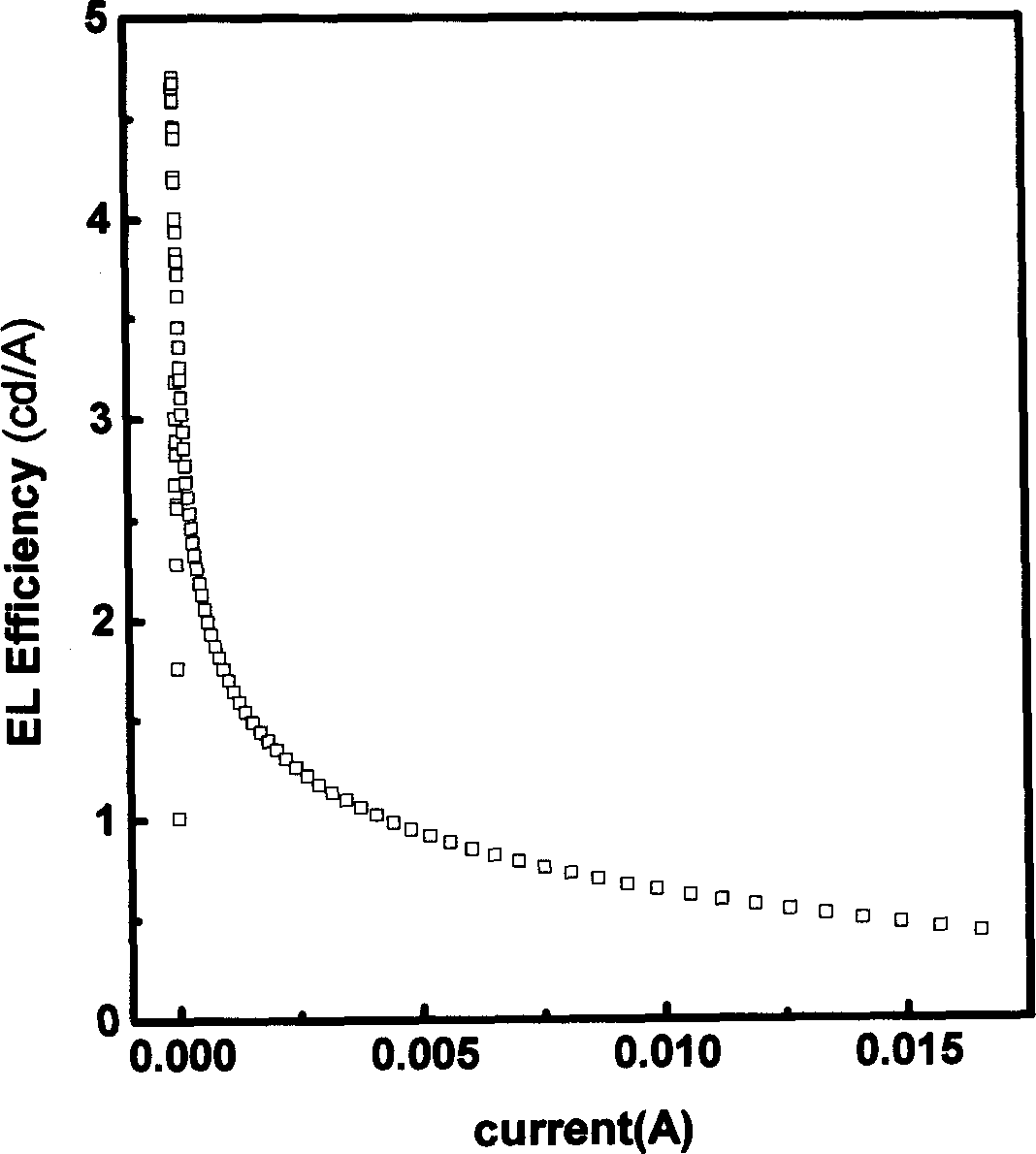

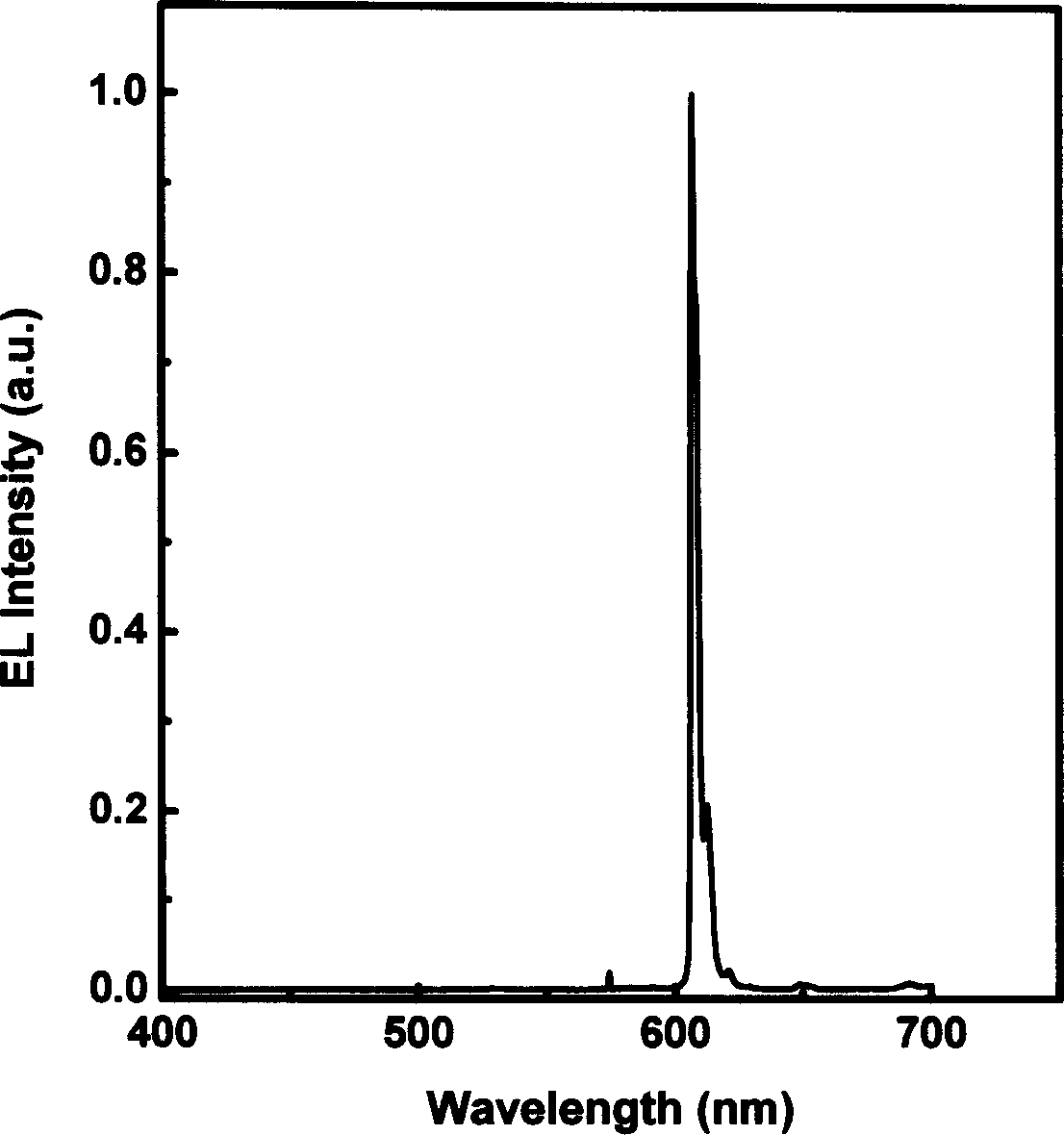

Embodiment 1

[0017] Get 3 mmoles of dibenzoylmethane (DBM) and 1 mmoles of 3,4,7,8-tetramethyl-1,10-phenanthroline and dissolve in ethanol, then add 3 mmoles of sodium hydroxide aqueous solution, under the condition of stirring and heating, slowly add 10 ml of 0.1 mmol / ml europium trichloride aqueous solution dropwise. Heat the reaction at 60°C for 30 minutes, wash the product with water and ethanol, and recrystallize to obtain Eu(DBM) 3 (Tmphen). with Eu(DBM) 3 (Tmphen) was prepared as ITO / TPD / Eu(DBM) 3 (Tmphen): CBP / BCP / AlQ / LiF / Al electroluminescent device, in a vacuum of 10 -3 Evaporate the organic and metal electrode layers under the pressure of Pa, the evaporation rate of the organic layer is controlled at 4 Å / s, the evaporation rate of LiF is controlled at 0.5 Å / s, the evaporation rate of the metal is controlled at 5 Å / s, and the doping concentration Controlled at 1%. Among them, the thickness of TPD layer is 40nm, Eu(DBM) 3 (Tmphen): CBP layer 30nm, BCP layer 20nm, AlQ layer 3...

Embodiment 2

[0019] Get 6 mmoles of dibenzoylmethane (DBM) and 2 mmoles of 3,4,7,8-tetramethyl-1,10-o-phenanthroline and dissolve in chloroform, then add 6 mmoles of triethylamine, Under the condition of stirring and heating, 20 ml of 0.1 mmol / ml europium trichloride ethanol solution was slowly added dropwise. Heat the reaction at 40°C for 1 hour, remove the reaction solvent to obtain Eu(DBM) 3 (Tmphen), washed with water, washed with ethanol, and recrystallized. with Eu(DBM) 3 (Tmphen) was prepared as ITO / TPD / Eu(DBM) 3 (Tmphen): CBP / BCP / AlQ / LiF / Al electroluminescent device, in a vacuum of 10 -4 Evaporate the organic and metal electrode layers under the pressure of Pa, the evaporation rate of the organic layer is controlled at 2 / s, the evaporation rate of LiF is controlled at 1 / s, the metal evaporation rate is controlled at 8 / s, and the doping concentration Controlled at 3%. Among them, the thickness of the TPD layer is 30nm, the Eu complex: CBP layer is 20nm, the BCP layer is 1...

Embodiment 3

[0021] Get 3 millimoles of trifluoroacetylthiophene acetone (TTA) and 1 millimole of 3,4,7,8-tetramethyl-1,10-o-phenanthroline and dissolve in ethanol, then add 3 millimoles of sodium hydroxide aqueous solution, under the condition of stirring and heating, slowly add 10 ml of 0.1 mmol / ml europium trichloride aqueous solution dropwise. Heat the reaction at 70°C for 4 hours, wash with water, wash with ethanol, and recrystallize to obtain Eu(TTA) 3 (Tmphen), with Eu(TTA) 3 (Tmphen) was prepared as ITO / TPD / Eu(TTA) 3 (Tmphen): CBP / BCP / AlQ / LiF / Al electroluminescent device, in a vacuum of 3×10 -6 The organic and metal electrode layers are evaporated under the pressure of Pa, the evaporation rate of the organic layer is controlled at 1 Å / s, the evaporation rate of LiF is controlled at 0.2 Å / s, the evaporation rate of the metal is controlled at 10 Å / s, and the doping concentration Control at 5%. Among them, the thickness of TPD layer is 35nm, Eu(TTA) 3 (Tmphen): CBP layer 250nm, B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com