Surface functionalized nano-particle and method for preparing its polymer nanometre composite material

A technology of surface functionalization and nano-particles, applied in chemical instruments and methods, luminescent materials, material inspection products, etc., can solve the problems of photophysical property degradation, opacity of composite materials, easy aggregation of nanoparticles, etc., and achieve good mechanical properties and The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

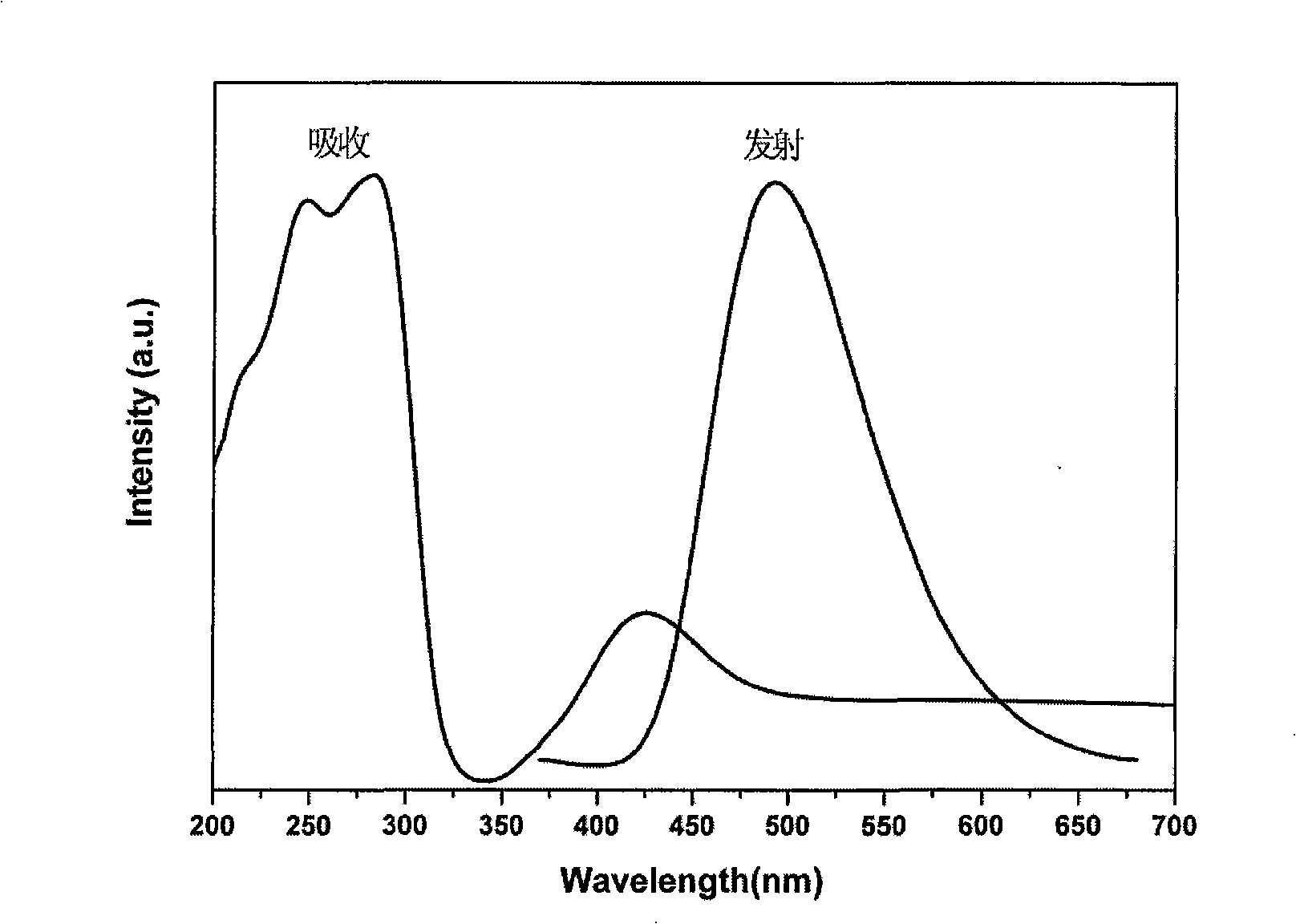

[0025] 1. Synthesis of ZnS composite nanoparticles functionalized with o-phenanthroline:

[0026] 5.1 g of thioacetamide, 16.5 g of zinc acetate and 8.0 mL of mercaptoethanol were dissolved in 150 mL of dimethylformamide (DMF). The reaction solution was heated at 70° C. for 6 h under nitrogen protection. The reaction solution was precipitated in ethanol, centrifuged, washed three times with absolute ethanol, and dried under vacuum at room temperature to finally obtain white ZnS nanoparticles. Get 1.0g of ZnS nanoparticles obtained above and disperse them in 25mL DMF (1), dissolve 0.02g o-phenanthroline in 5mL DMF (2), then add the solution (2) dropwise to the solution (1), and control the rate of addition to 0.5 mL / min, the mixed solution was reacted at 45°C for 10h. Then cool to room temperature, add a large amount of ethanol for precipitation, centrifuge, ultrasonically wash three times with absolute ethanol, wash once with ether, and vacuum-dry at room temperature to fina...

Embodiment 2

[0033] 1. Synthesis of ZnS composite nanoparticles functionalized with 5-aminophenanthroline:

[0034] The synthetic method is the same as described in Example 1, and the only difference is to replace o-phenanthroline with 5-amino-phenanthroline;

[0035] 2. Preparation of ZnS composite nanoparticle / polymer bulk material:

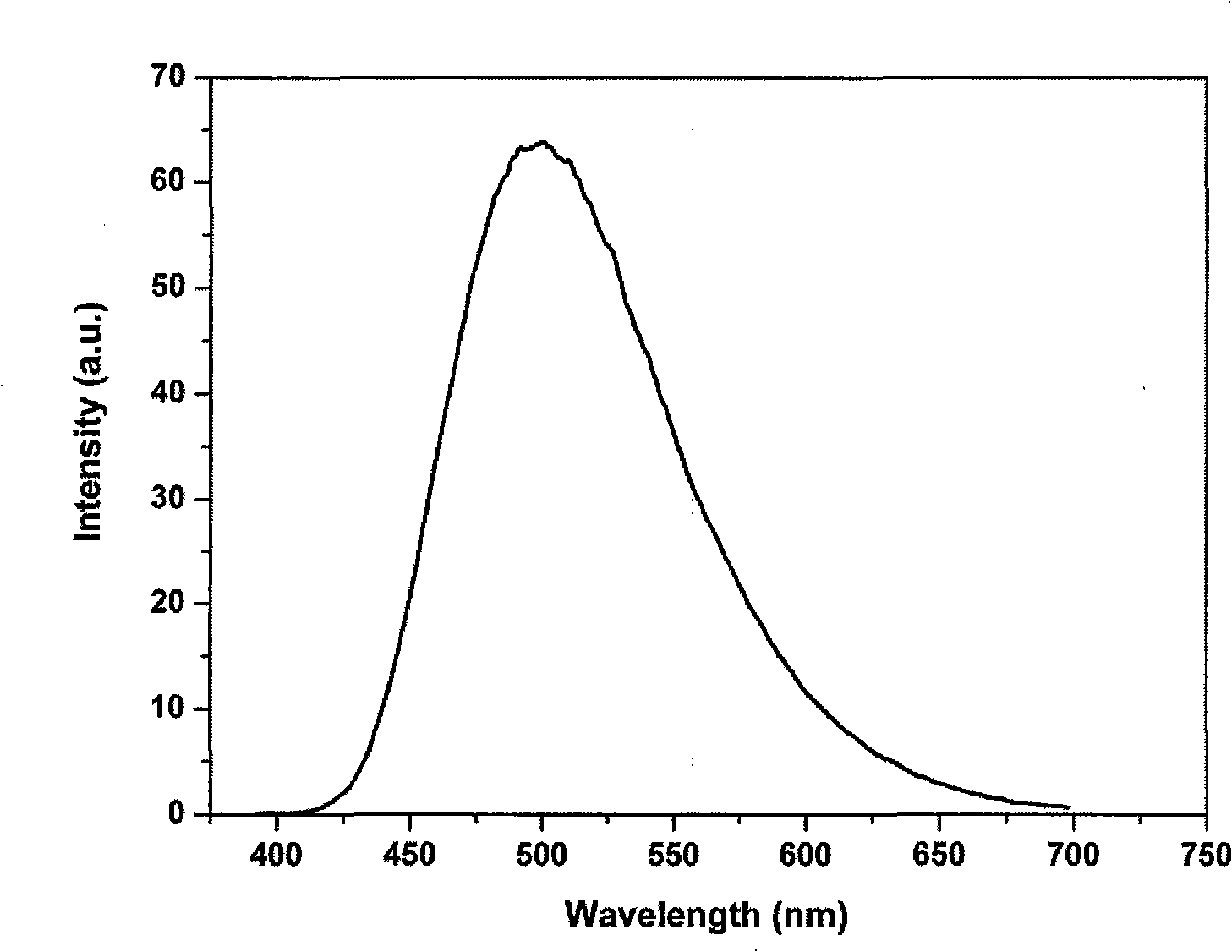

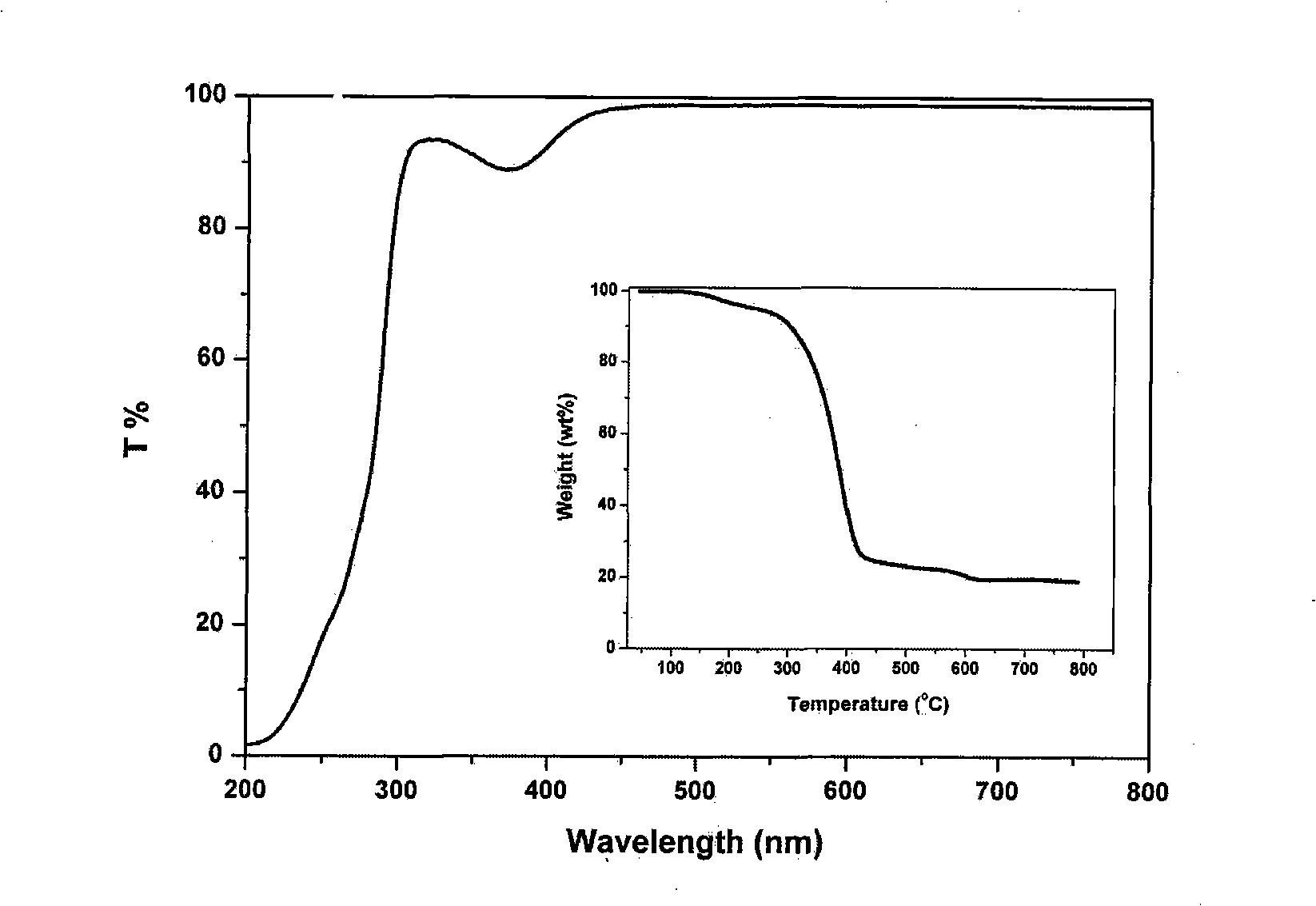

[0036] Add 0.5g of ZnS composite nanoparticles to 10g of mixed monomers of styrene and dimethylacrylamide (the weight ratio is 1:1), disperse into a uniform and transparent solution by ultrasonic oscillation at 50°C, and then add 0.4% AIBN initiator , Seal, degas, fully remove the gas in the system and pour the liquid into the glass mold. Polymerization conditions: polymerize at 40°C for 12 hours, program temperature rise, increase temperature by 10°C every 1 hour, and finally heat-treat at 120°C for 4 hours. The ZnS composite nanoparticle / polymer transparent optical bulk phase material can be obtained after demoulding. In this nano-composite phase mater...

Embodiment 3

[0038] 1. The method for synthesizing 5-amino-phenanthroline functionalized ZnS composite nanoparticles is as described in Example 2;

[0039] 2. Preparation of ZnS composite nanoparticle / polymer bulk material:

[0040] 0.5 g of ZnS composite nanoparticles were dispersed into 10 g of mixed monomers of dimethylacrylamide and styrene (weight ratio 1.5:1) under the action of ultrasonic waves, and then 0.2 g of acrylic acid and 0.25 wt % BPO were added. After sealing, degassing, and fully removing the gas in the system, pour the liquid into the glass mold. Polymerize at 60°C for 6 hours, program temperature rise, increase the temperature by 10°C every hour, and finally heat-treat at 150°C for 2 hours. The ZnS composite nanoparticle / polymer transparent optical bulk phase material can be obtained after demolding. The bulk material exhibits better fluorescence emission properties around 540nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com