Separation method of composition containing 4-aminodiamine and its equipment

A technology of aminodiphenylamine and separation method, which is applied in the field of composition separation method and its equipment, can solve the problems of decreased recovery rate of composite alkali catalyst, difficult control of water phase evaporation time, low decomposition rate of heat-sensitive substances, etc., and achieve continuous Good separation effect, continuous and effective separation, short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

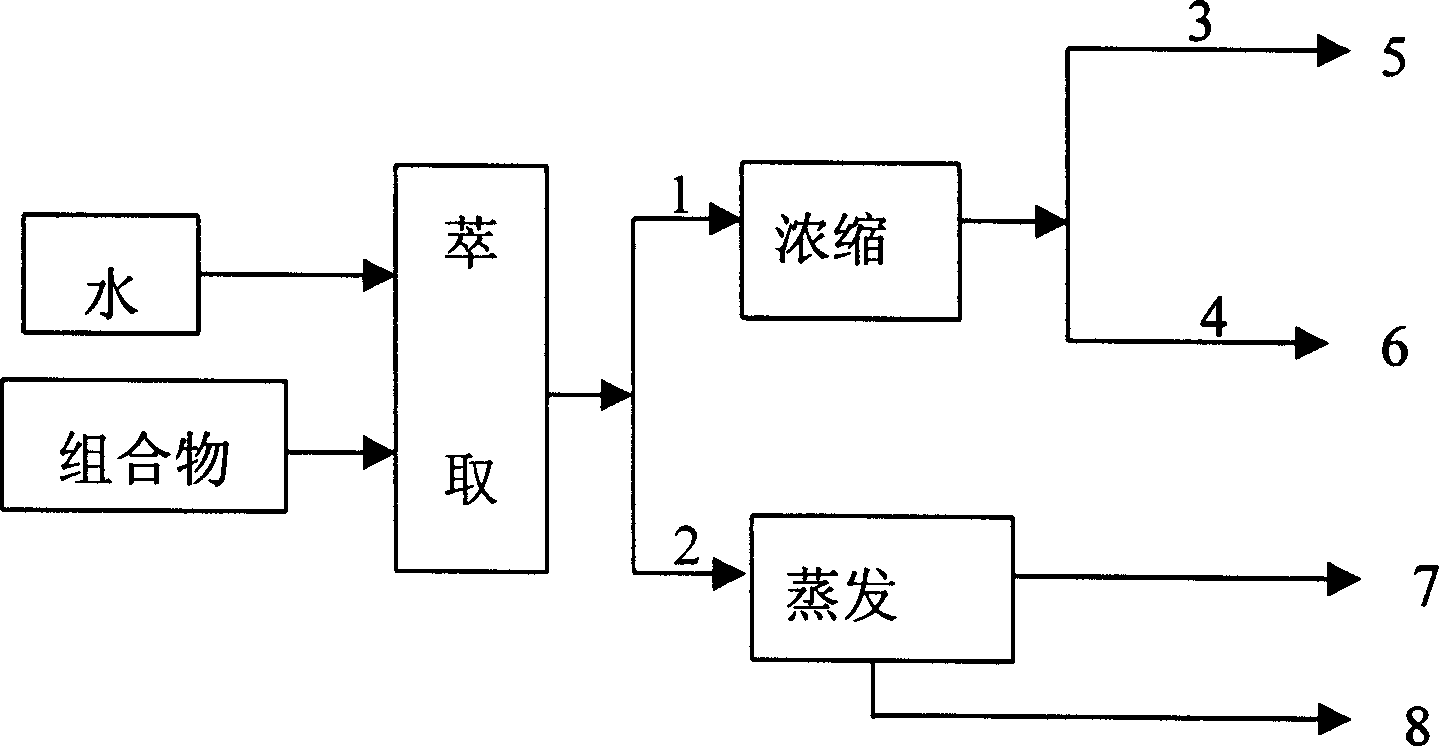

Method used

Image

Examples

Embodiment 1

[0029] Composition (wherein the hydrogenation solvent is methyl alcohol) is transported into the top and the bottom of the tower of the extraction tower with the flow rate of 580 liters / hour and the water of the same flow rate with a metering pump, and the auxiliary extractant is selected polypropylene glycol ether for use at a rate of 6 liters / hour The flow rate continuously enters the extraction tower. The extraction tower is a packed tower under normal pressure, and the temperature is 30-50°C. The extracted water phase and organic phase enter the water phase storage tank and the organic phase storage tank respectively, and the obtained water phase flow rate is 767 liters / hour, and the flow rate of the organic phase is 393 liters / hour. A small amount of organic phase can be taken and washed fully with equal volume deionized water. The extraction rate of the organic phase is 97.1%

[0030]Preheat the 767 liters / hour water phase to 80°C and enter the top of the normal pressure...

Embodiment 2

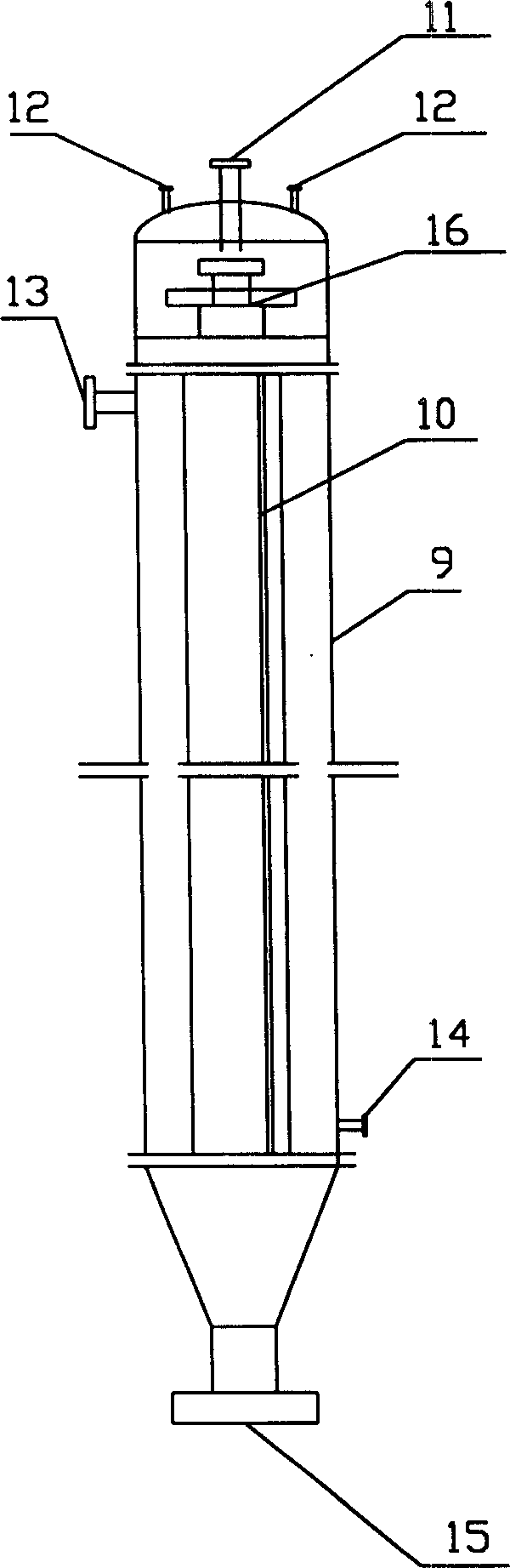

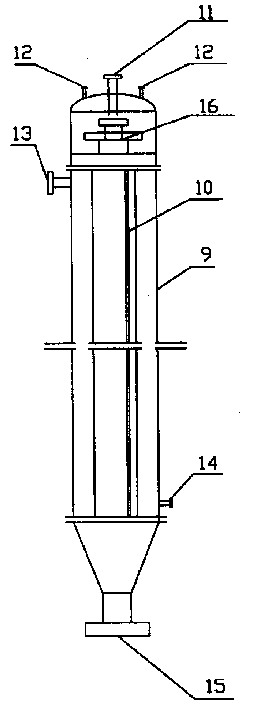

[0034] The present invention adopts a two-effect gas-assisted flow falling film evaporator, and each effect gas-assisted flow falling film evaporator includes a shell side 9, a tube side 10, a steam inlet 13 installed at the upper end of the shell side 9, and a steam inlet 13 installed at the lower end of the shell side 9. Condensed water outlet 14, low-concentration water phase inlet 11 installed at the top of the tube pass 10, high-concentration water phase outlet 15 installed at the bottom of the tube pass 10, five steam inlets 12 evenly installed on the top of the tube pass 10, that is, flow aid mouth, the distribution plate 16 is installed below the low-concentration aqueous phase inlet 11.

[0035] In the two-effect gas-assisted falling film evaporator adopted in the present invention, its shell side 9 is heated by steam, the water phase goes through the tube side 10, and there is also one way of steam from the steam port 12 on the top of the first-effect falling film eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com