Preparation method of graphene aqueous solution and graphene nanosheet

A technology of graphene nanosheets and olefin aqueous solution, applied in the field of graphene, can solve the problems of low purity of graphene and failure to meet high purity requirements, and achieve the effect of improving efficiency and output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

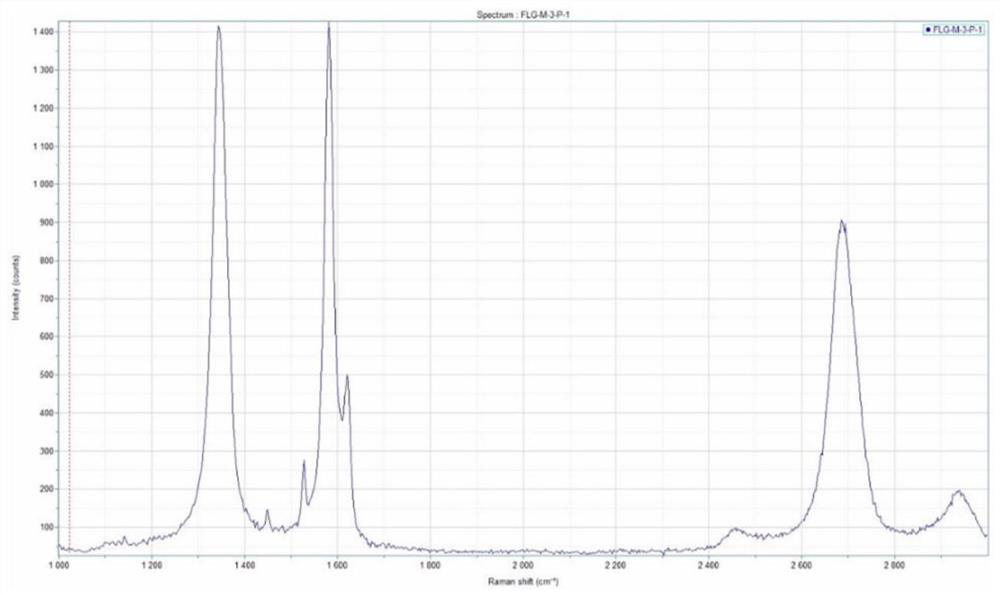

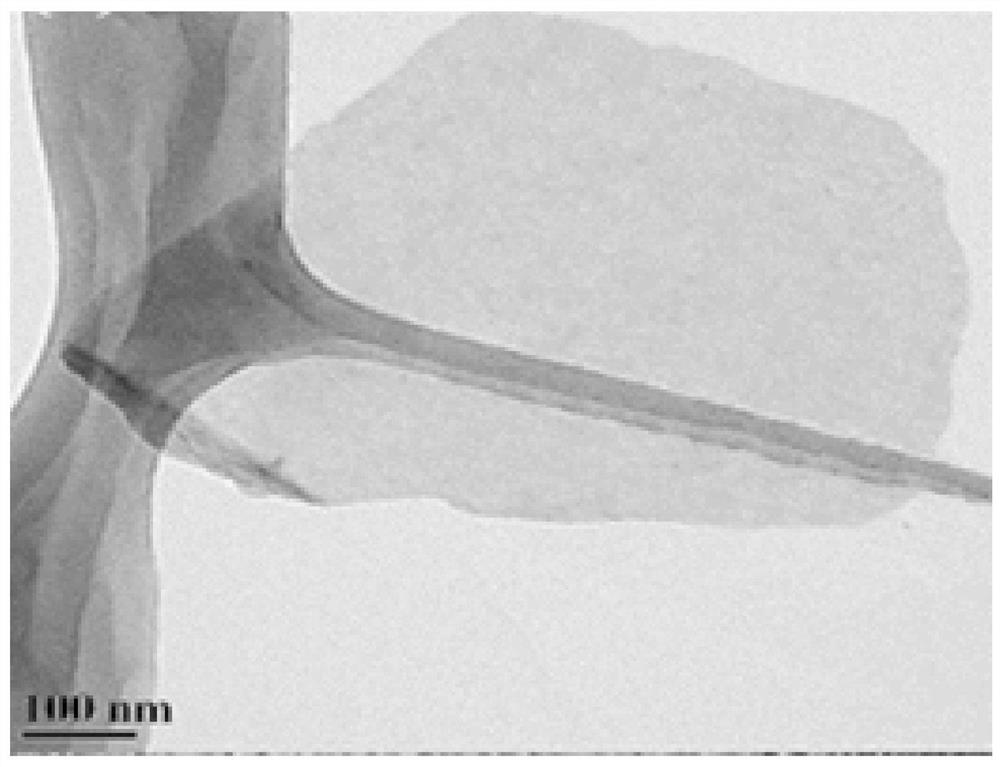

[0036]A graphene aqueous solution and a method for preparing graphene nanosheets, wherein the solid substances in the graphene aqueous solution are very few-layer graphene, few-layer graphene and multi-layer graphene. The number of layers of very few-layer graphene is 1-3 layers, the number of layers of few-layer graphene is 4-5 layers, and the number of layers of multi-layer graphene is 6-10 layers. The number of layers of graphene nanosheets is 11 to 500 layers.

[0037] First, the selection and screening of raw materials are carried out. Selection of raw materials: natural graphite particles are selected, and natural graphite particles are selected because natural graphite particles have low artificial energy consumption and relatively low cost when dispersing and separating, while artificially synthesized graphite particles are disintegrating and separating. The energy consumption is huge, it is not easy to separate, and the cost is relatively high. Raw material sieving:...

Embodiment 1

[0039] Step (1) Add 200 grams of sodium deoxycholate SDC into 20 liters of deionized water (conductivity 0.08 μs / cm), and then add 1000 grams of sieved natural graphite particles to obtain a colloidal suspension.

[0040] Step (2) stirring and shearing: the colloidal suspension is stirred and sheared by a shearing device, the working speed of the shearing device is 8000 rpm, and the working time is 8 hours to obtain a colloidal solution in the form of stable graphite particles. The solid substances in the colloidal solution include few-layer graphene, multi-layer graphene, graphene nanosheets and graphite particles. In the process of stirring and shearing, a defoamer is added, and the defoamer is an industrial water-based defoamer.

[0041] Step (3) Ultrasonic vibration: the colloidal solution is introduced into an ultrasonic machine or an ultrasonic electrode machine, and ultrasonically oscillated for 2 hours at room temperature, and the ultrasonic frequency is 40 kHz.

[00...

Embodiment 2

[0047] Step (1) Add 100 grams of sodium deoxycholate SDC into 15 liters of deionized water (conductivity 0.1 μs / cm), and then add 1000 grams of sieved natural graphite particles to obtain a colloidal suspension.

[0048] Step (2) stirring and shearing: the colloidal suspension is stirred and sheared by a shearing device, the working speed of the shearing device is 10,000 rpm, and the working time is 6 hours to obtain a colloidal solution in the form of stable graphite particles. The solid substances in the colloidal solution include few-layer graphene, multi-layer graphene, graphene nanosheets and graphite particles.

[0049] Step (3) ultrasonic vibration: the colloidal solution is introduced into the ultrasonic machine or the ultrasonic electrode machine, and the ultrasonic vibration is carried out for 3 hours at normal temperature, and the ultrasonic frequency is 20 kHz.

[0050] Step (4) high-pressure emulsification: place the oscillated colloidal solution in a high-pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com