Preparation method of nanometer microgranule modified polyacrylonitrile anti static fiber

A polyacrylonitrile fiber, antistatic fiber technology, applied in the direction of conductive / antistatic filament manufacturing, fiber chemical characteristics, single-component synthetic polymer rayon, etc., can solve the problems of easy clogging of spinnerets, fiber mechanical properties, Dyeing performance decline and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

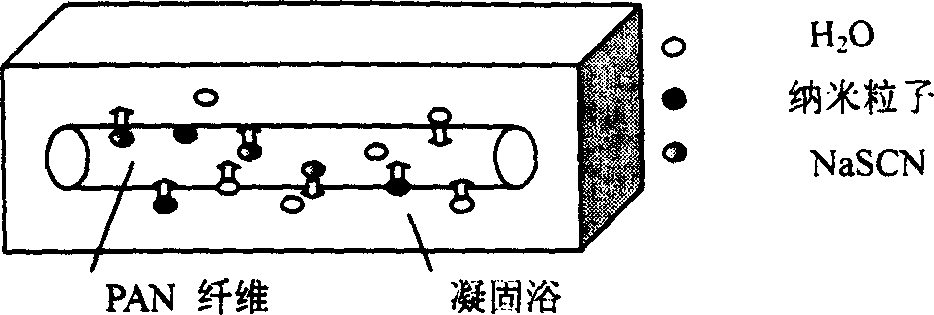

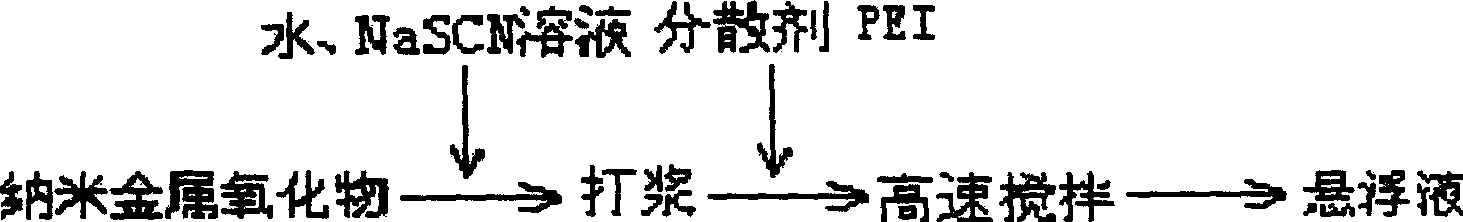

[0023] Add nano-ATO (about 130 nanometers) in the NaSCN aqueous solution that is 10% by weight fraction, the weight percentage of ATO is 12%, beating with high-speed mixer 30 minutes, adding weight fraction in suspension is 4%

[0024] (relative to ATO) dispersant polyethyleneimine, then stirred at high speed for 30 minutes, cooled to about 5°C to obtain a coagulation bath (ATO particle size in the bath is about 140 nanometers), and then spun according to the spinning process ①, The sample number is 2.

Embodiment 2

[0026] Add nano-ATO (about 130 nanometers) in deionized water, the weight percentage of ATO is 0.5%, beating with a high-speed mixer for 30 minutes, and adding the dispersant polyethyleneimine with a weight fraction of 4% (relative to ATO) in the suspension , then stirred at high speed for 30 minutes, heated to about 60°C to obtain a preheating bath (ATO particle size in the bath is about 130 nm), dissolved PAN in NaSCN solution, and used this as the spinning stock solution, according to the spinning process② Spinning was carried out and the sample number was 3.

Embodiment 3

[0028] Add nano-ATO (about 130 nanometers) in deionized water, the weight percentage of ATO is 5%, beating with a high-speed mixer for 30 minutes, and adding the dispersant polyethyleneimine with a weight fraction of 4% (relative to ATO) in the suspension , then stirred at high speed for 30 minutes, heated to about 60°C to obtain a preheating bath (ATO particle size in the bath is about 130 nm), dissolved PAN in NaSCN solution, and used this as the spinning stock solution, according to the spinning process② Spinning was carried out, and the sample number was 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com