Galvanization apparatus and process of tube-type crystallizer

A technology of tubular crystallizer and electroplating equipment, which is applied in the field of electroplating tungsten-cobalt alloy and tubular crystallizer electroplating equipment, and achieves the effects of preventing the coating layer from falling off into pieces, low stress and easy disposal of waste liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

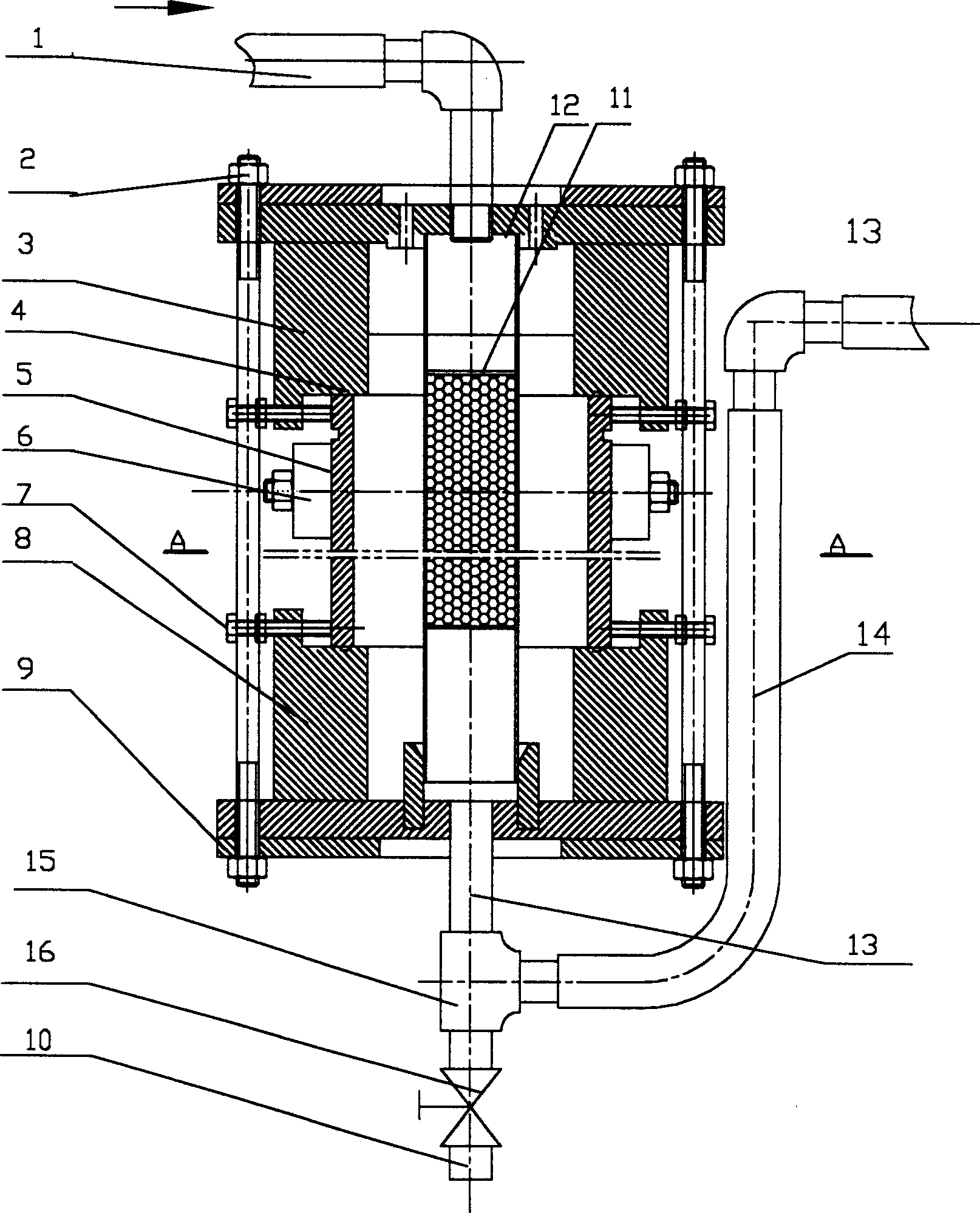

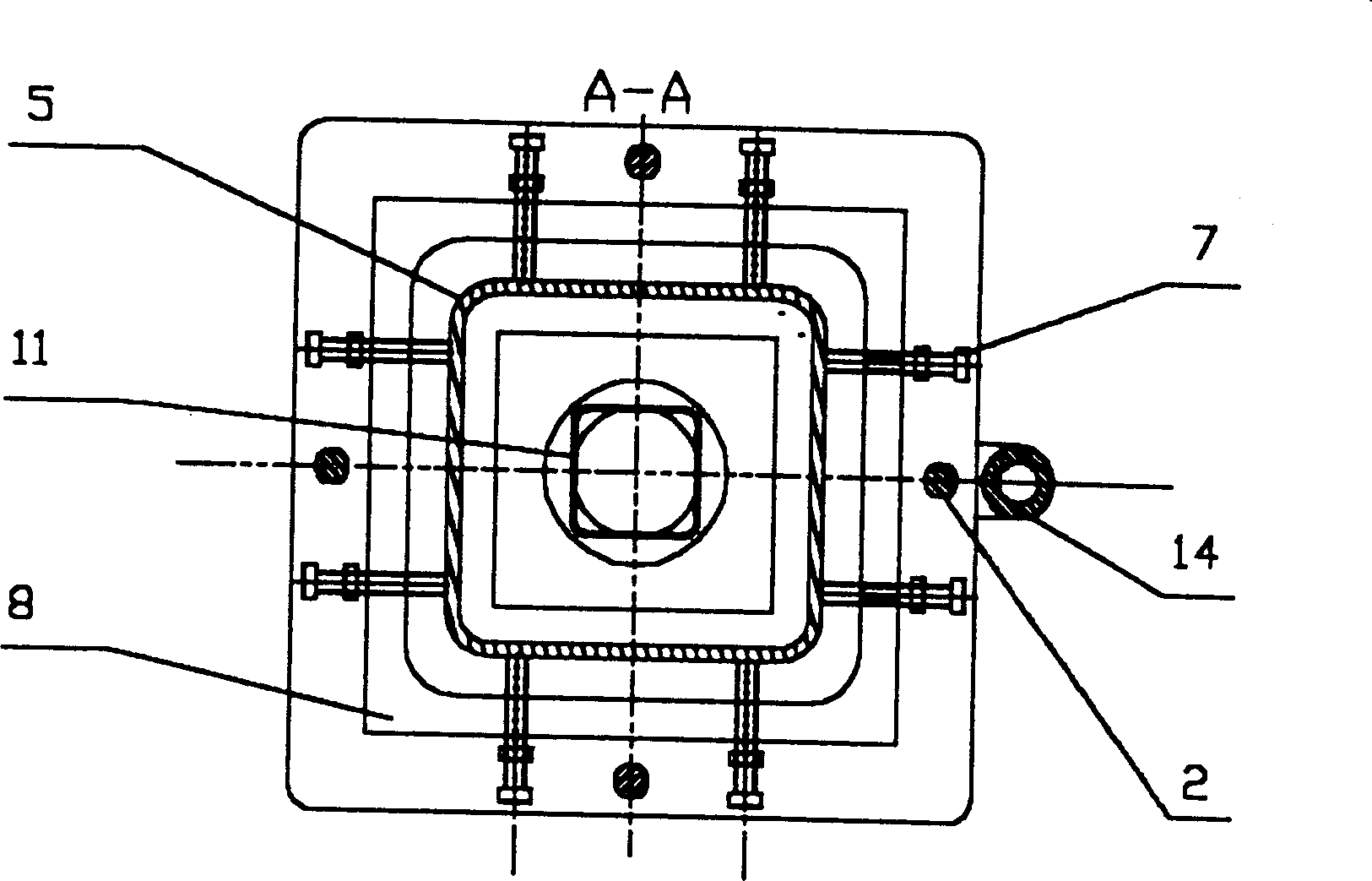

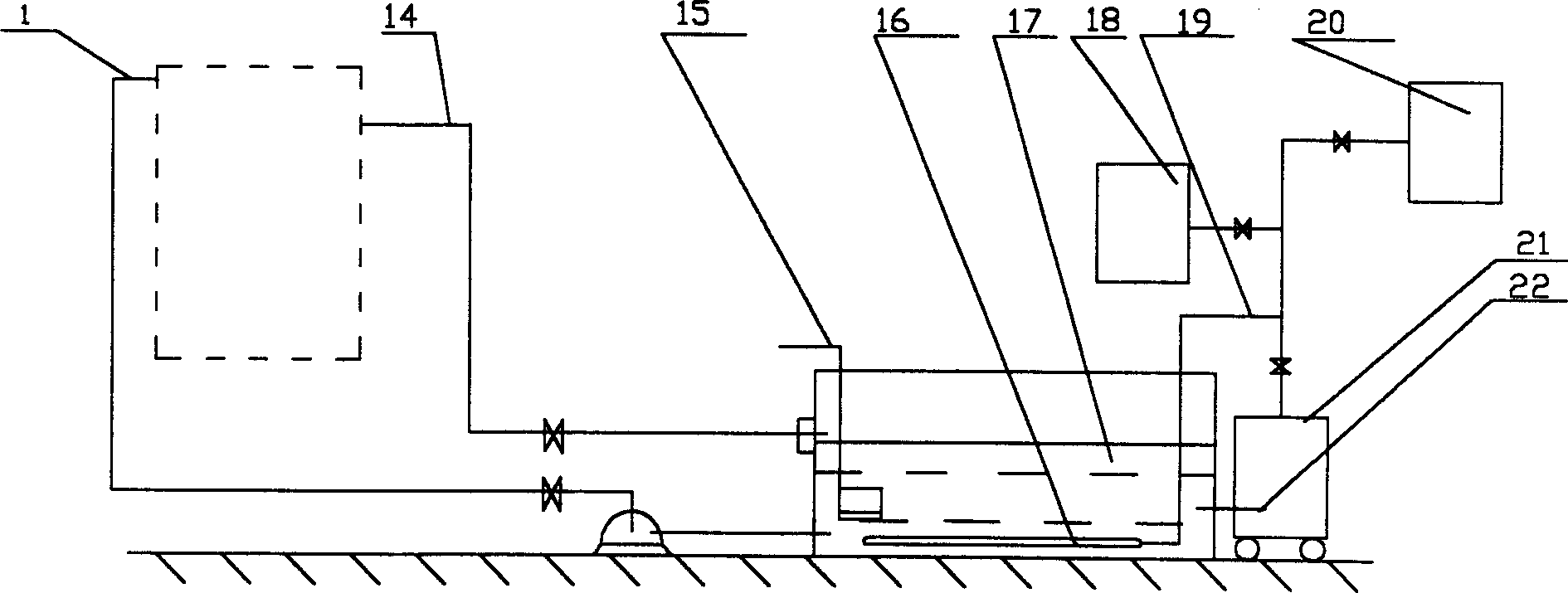

[0030] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0031] like figure 1 , 2 , Shown in 3, tubular crystallizer electroplating equipment of the present invention comprises plating solution storage tank 17, temperature control heater and electrolytic purification device 15, filter 21, filter suction pipeline 16, filter inlet pipe 19 , filter return liquid pipeline 22, PH value controller 18, AD486 automatic adding device 20, plating solution return pipeline 14, crossing liquid input pipeline 1, it is characterized in that this electroplating equipment has an electroplating tank, is used as electroplating cathode Tubular crystallizer copper tube 5, clamping upper sealing cover 3 of the fixture for copper tube 5, lower sealing cover 8 of the fixture, and cathode splint 6 clamped on the side of copper tube 5 are formed. The square columnar anode titanium basket 11 and its anode frame 12 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com