Yarn layer breadth-determining spinning mechanism of warper

A winding mechanism and width-fixing technology, which is applied in the textile field, can solve problems such as disordered yarn stacking order, unfixable width, troublesome weaving beam rewinding, etc., so as to achieve regular and orderly stacking of yarn layers and wide warping width. Controllable, good unwinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

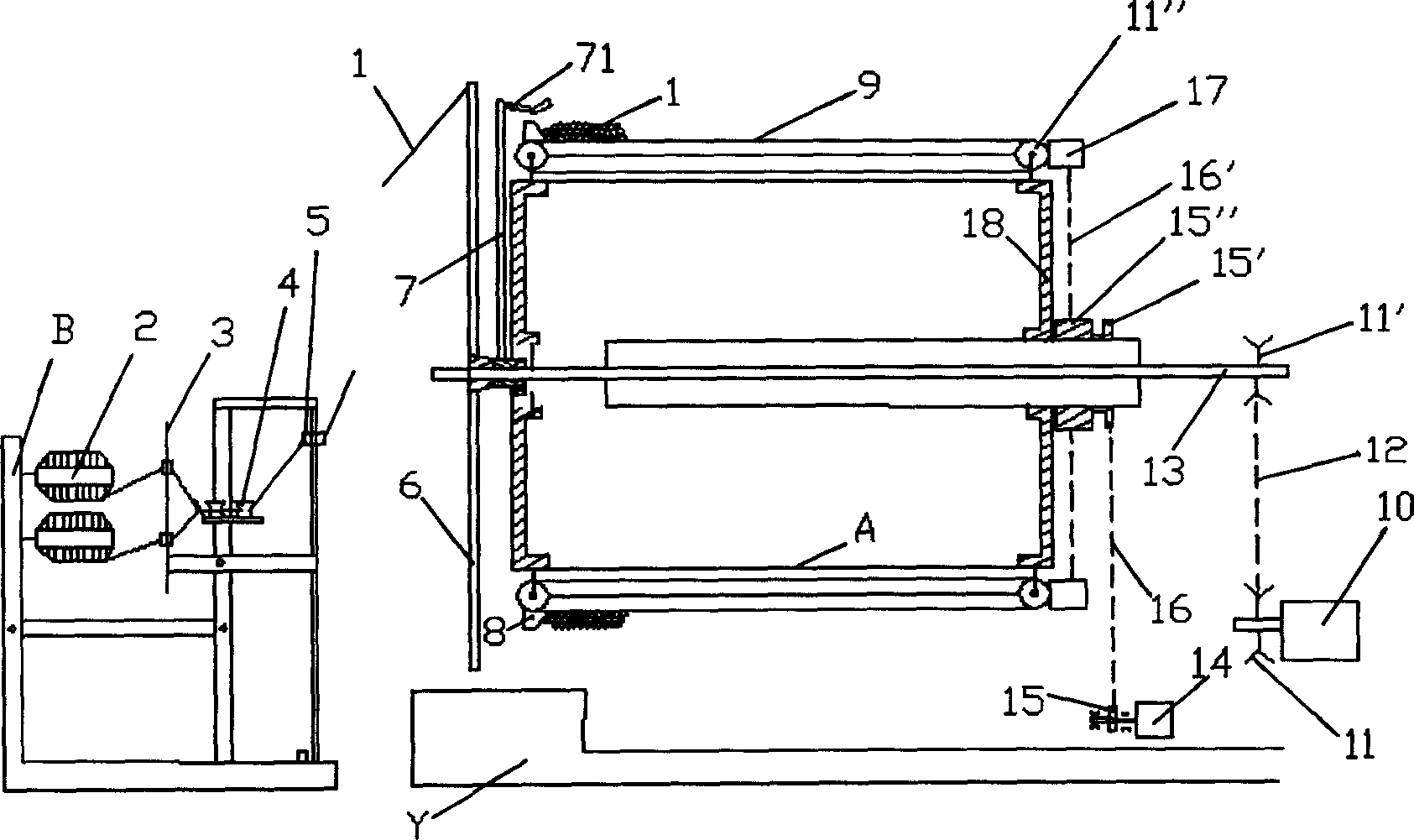

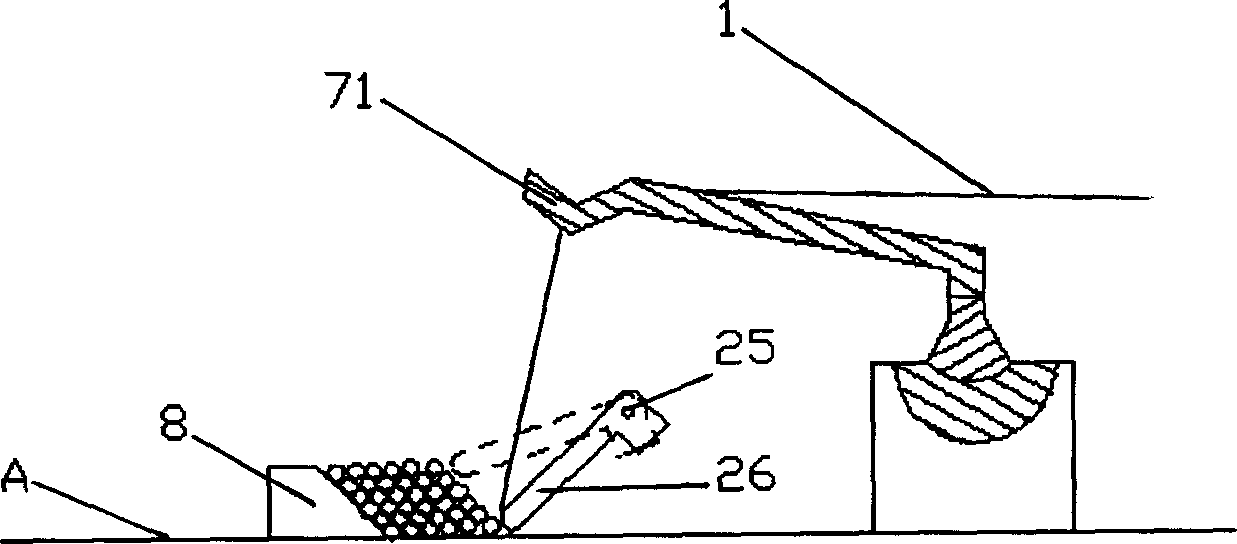

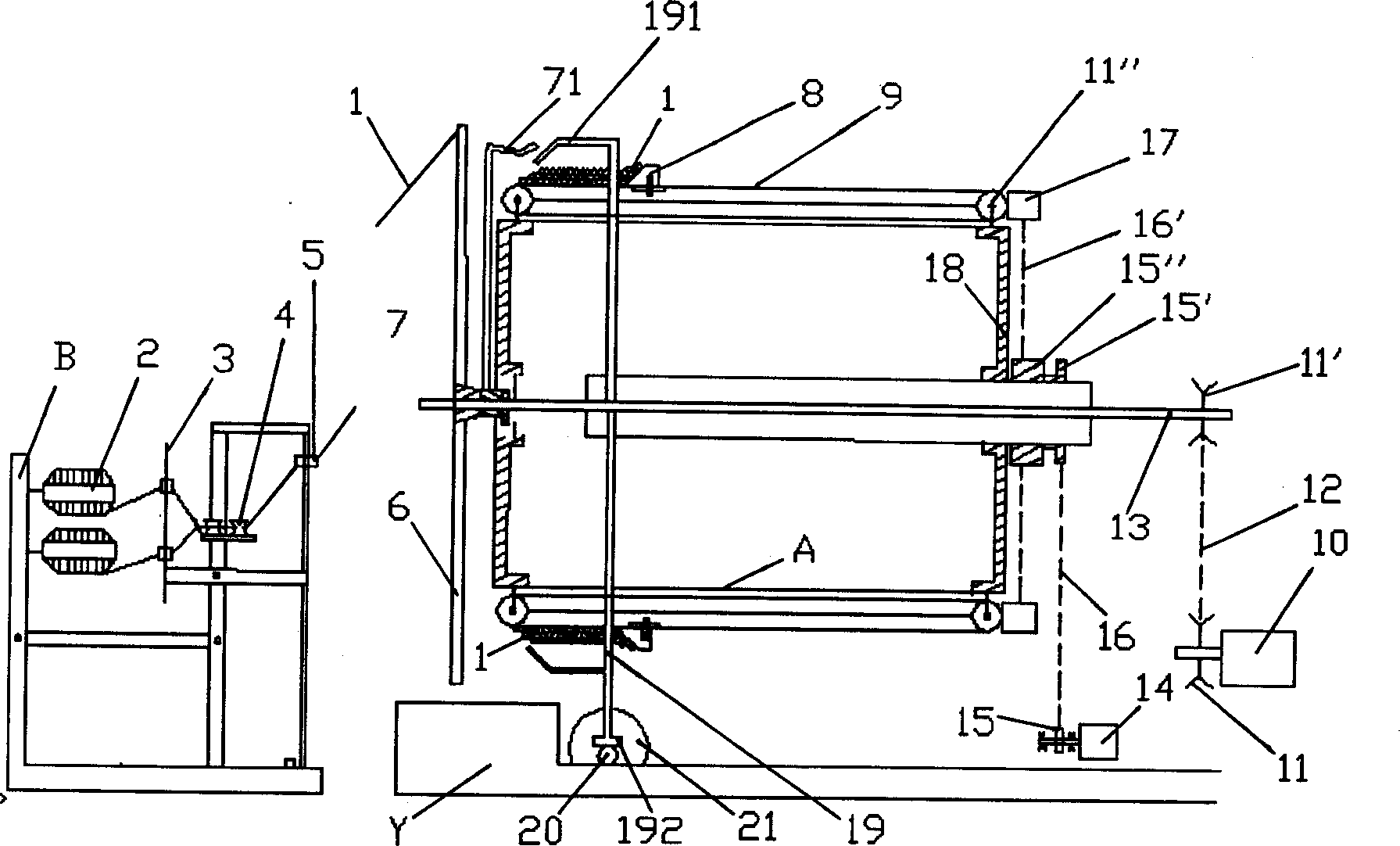

[0023] A fixed and regular winding mechanism for a sample warping machine yarn layer, which includes a creel B, a guide plate 3, a tension disc 4, a tension ring 5, a support disc 6, a yarn winding rod 7, a yarn winding finger 71, and an inclined block 8. Toothed conveyor belt 9, AC variable frequency motor 10, toothed wheel 11, 11', toothed belt 12, drive shaft 13, servo motor 14, sprocket 15, 15', 15", chain 16, 16', gear Box 17, wheel spoke 18, cylinder A, base Y, is characterized in that it also comprises guide bar frame 19, and its inner wall is the guide bar 191 of uniform distribution, and its outer circle has three tooth racks 192 stretched out at three places on the left and right , it meshes with the three left and right gears 20 through the three left and right racks 192, and the three left and right gears 20 are respectively fixed on the shaft ends of the three left and right stepper motors 21 and meshed with the three left and right racks 192. The three stepping m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com