Bag type artificial vitreous body and its mfg method

A manufacturing method and vitreous body technology, applied in ophthalmic treatment, eye implants, etc., can solve the problems of high price, lack of long-term observation of intraocular toxicity, and unaffordable patients, so as to save eyesight, reduce surgical recurrence rate, reduce The effect of recurrence chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

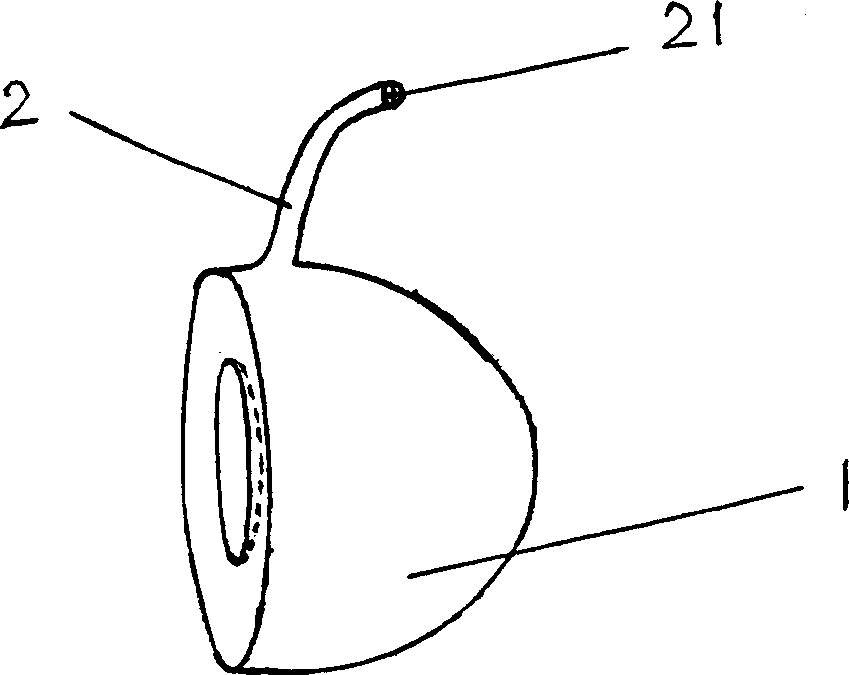

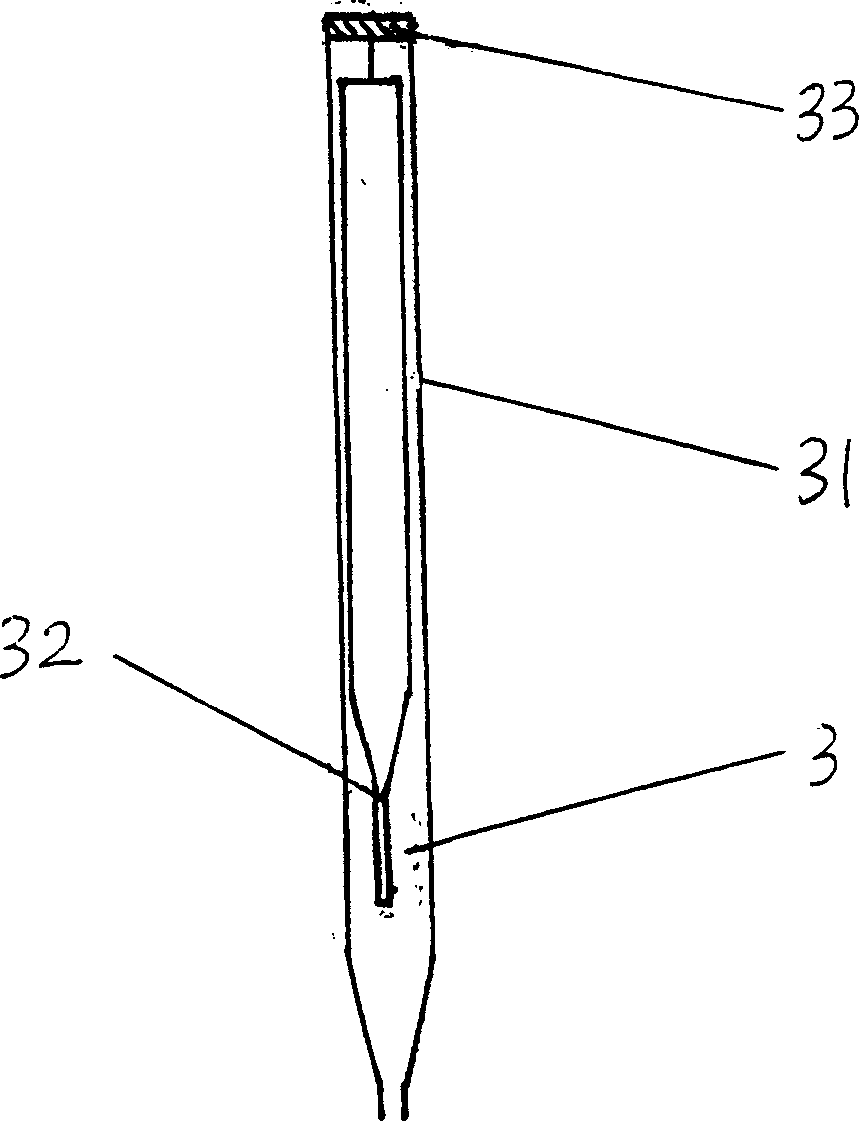

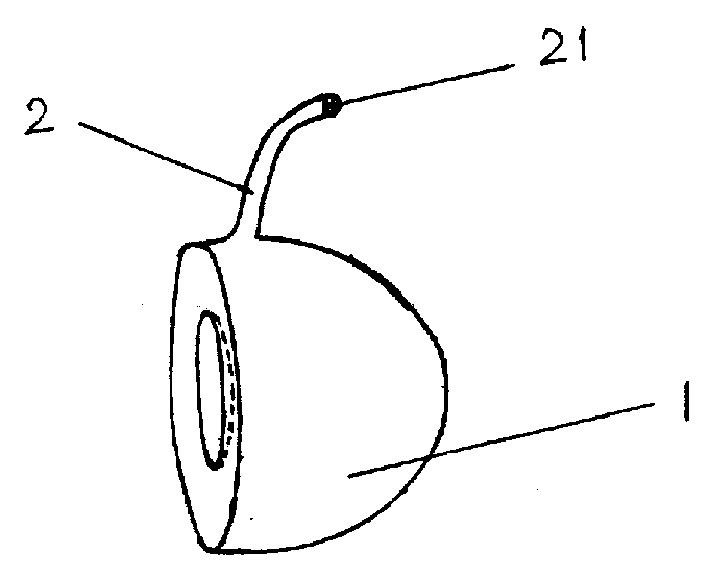

[0015] Based on this idea, this research designed an adjustable intraocular pressure polymer film capsular artificial vitreous system to achieve this goal. The system includes: polymer membrane bag, drainage and ejection handle. The polymer film is synthesized first, and ethylene and vinyl acetate copolymer is used as the polymer film material. According to the shape and volume of the vitreous cavity of the human eye, a polymer film is used to make a pouch. Drainage is connected to the top of the capsular bag. It is a long drainage tube with a one-way pressure-sensitive valve. Water can be injected through the drainage valve and fixed under the conjunctiva. When the intraocular pressure exceeds normal, the water in the capsular bag will automatically flow out. ; The ejection handle is a device that assists in the implantation of the membrane bag and drainage in the operation, and is composed of a shell, a spring core and a switch. The shell is cylindrical, with a diameter of 8mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com