Warming and cooling semiconductor cup

A semiconductor and water cup technology, applied in the field of semiconductor cold and warm water cups, can solve the problems of affecting product performance, poor sealing performance, poor thermal insulation performance, etc., and achieve the effect of reducing production cost, reducing energy consumption, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

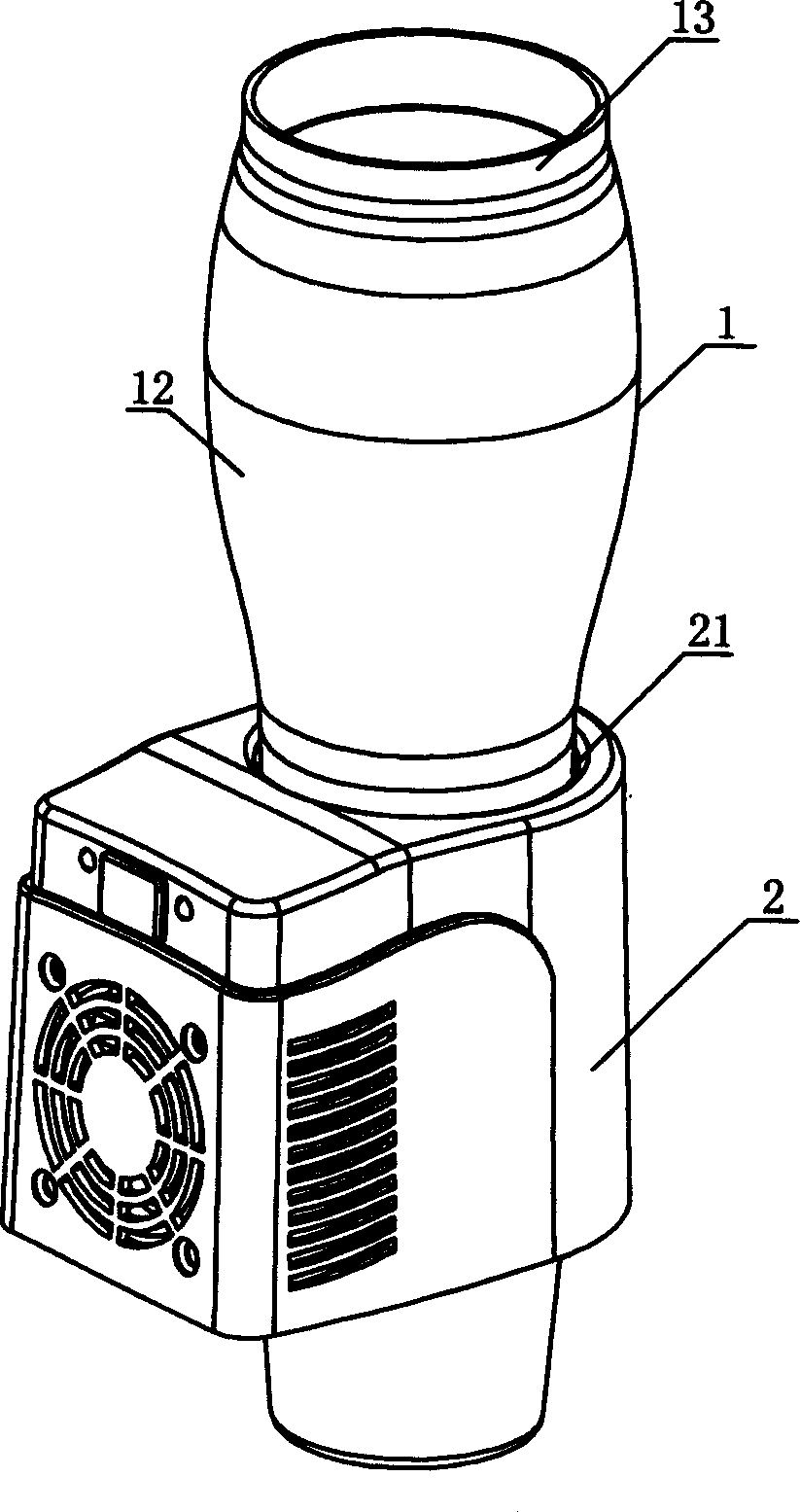

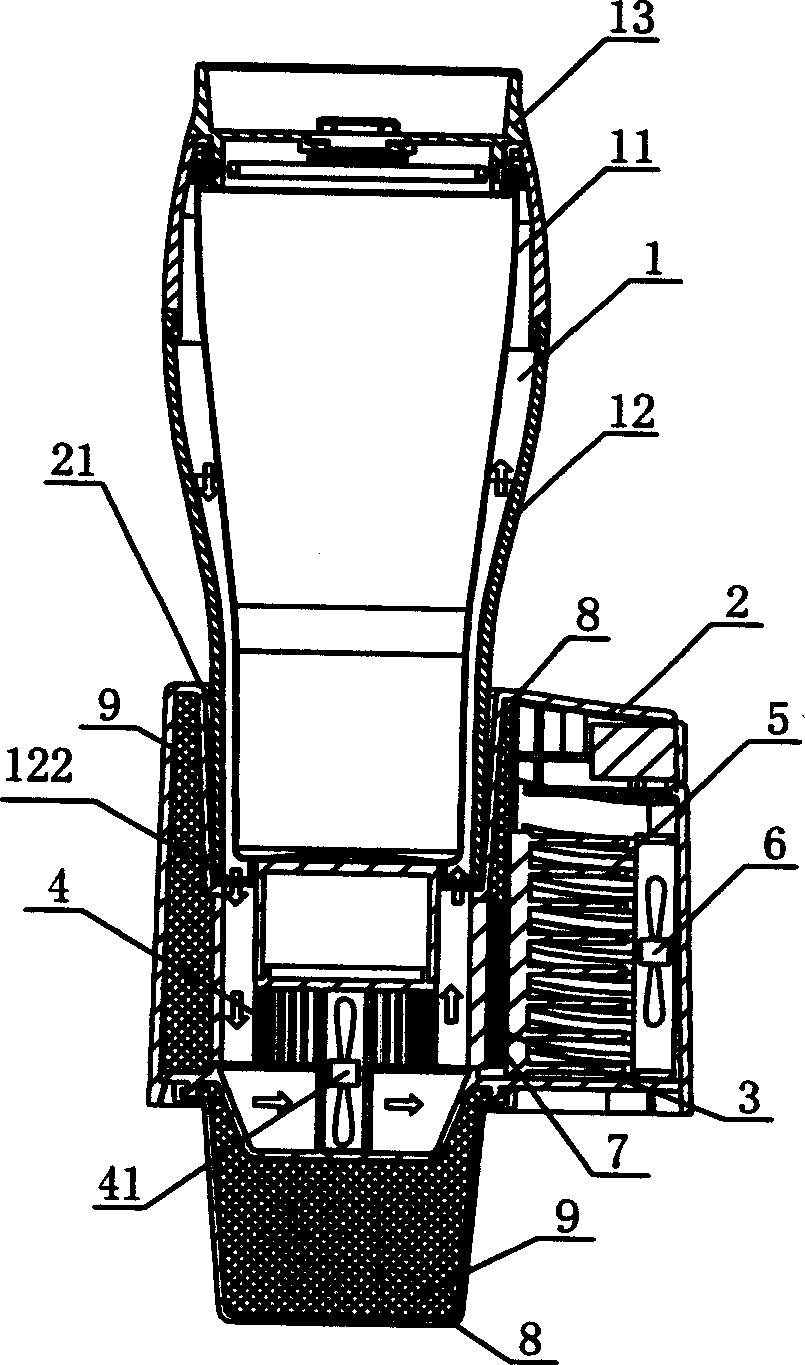

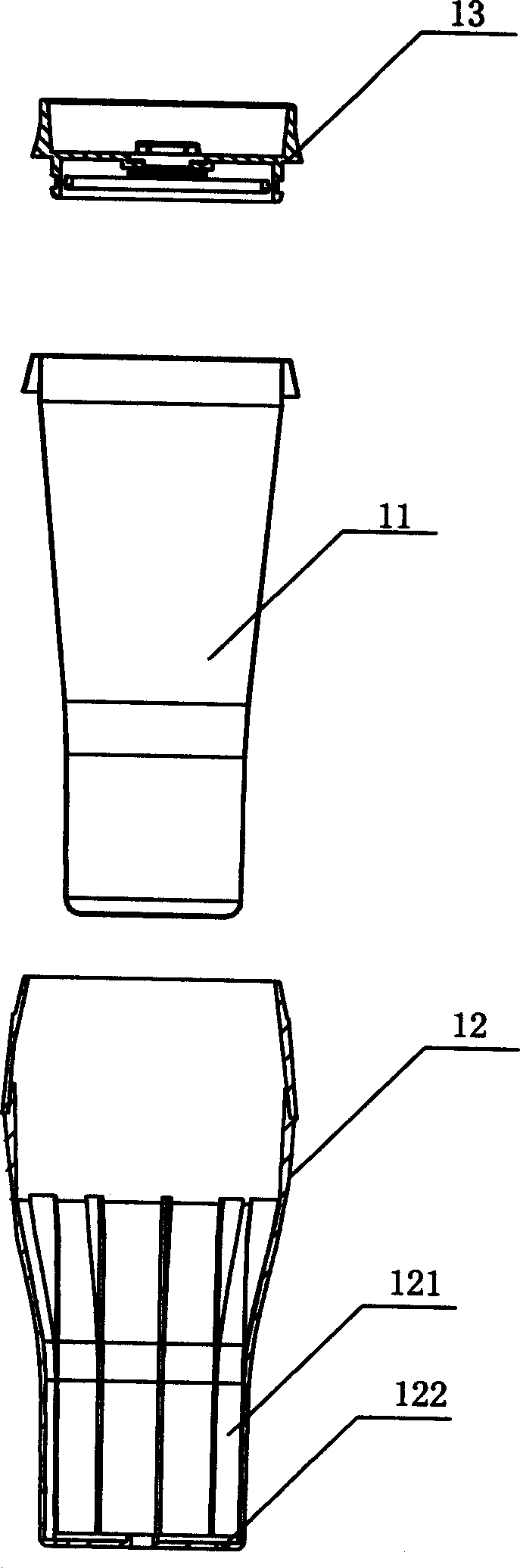

[0020] combine figure 1 , figure 2 and Figure 5 , the present invention is a semiconductor cold and warm water cup, which is characterized in that it mainly includes a water cup (1), a base (2), a semiconductor cooler (3), a heat exchanger (4), a radiator (5) and a cooling fan (6 ), the upper part of the base (2) is provided with a cup holder (21), and the semiconductor cooler (3), heat exchanger (4), radiator (5) and cooling fan (6) are installed in the inner cavity of the base (2) Among them, the heat exchanger (4) is located at the bottom of the cup holder (21), the radiator (5) is installed on the heat transfer surface (7) of the semiconductor cooler (3), and the heat exchanger (4) and the base (2 ) and between the heat exchanger (4) and the radiator (5) are provided with a heat insulating chamber (8), and the heat insulating chamber (8) is filled with a foaming material (9). The foaming material of this embodiment (9) It is a rigid polyurethane foam material, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com