Waterproof and heat holding hard polyether ester with asphalf mixed for building and its prepn process

A technology of polyurethane rigid foam and polyetherester, which is used in building thermal insulation materials, buildings, building components, etc., to achieve the effect of simplifying construction procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

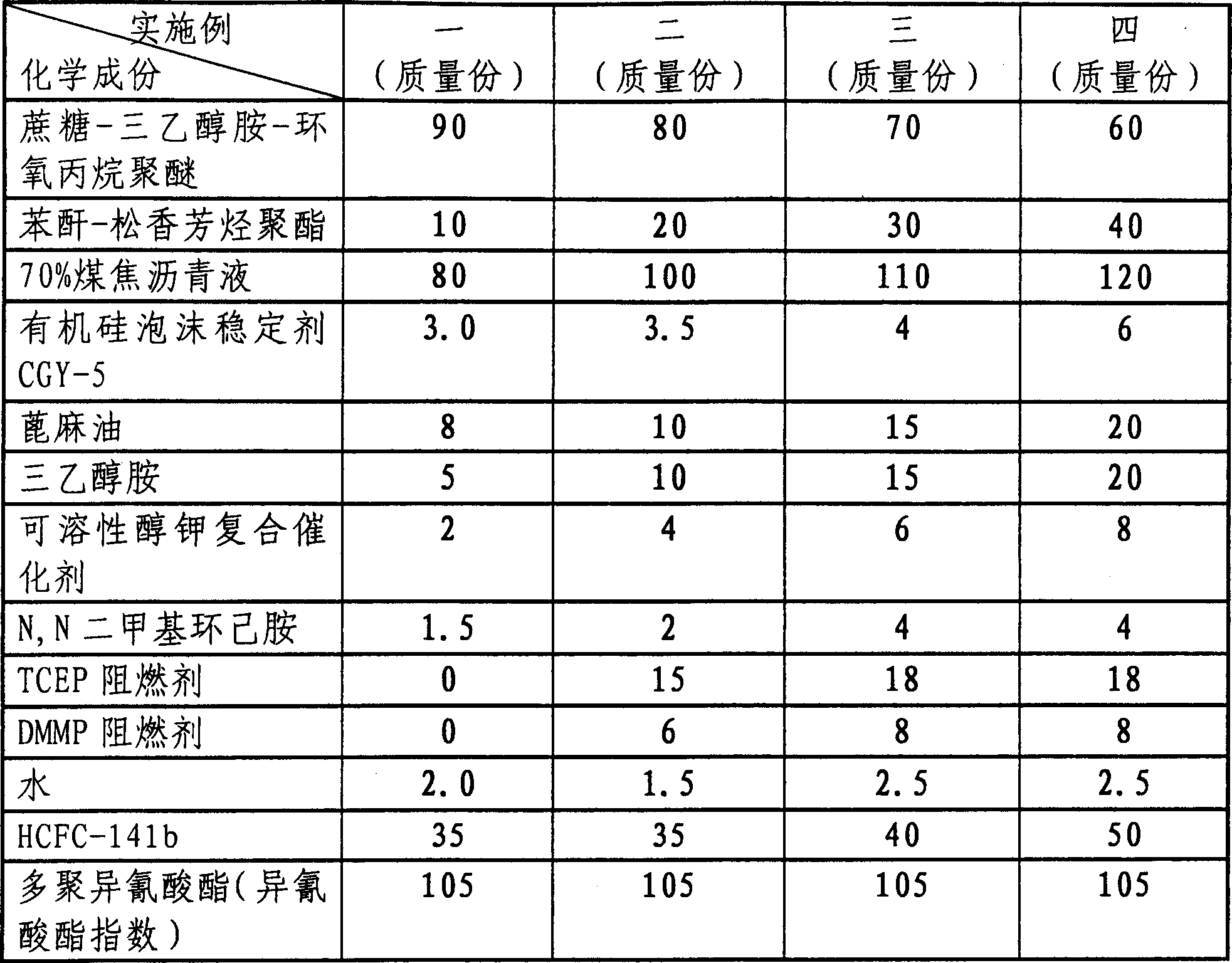

[0042] The embodiments of the present invention further specifically illustrate the feasibility and reliability of the polyether ester polyurethane rigid foam mixed with asphalt, but the present invention is not limited to the following examples, and the present invention is disclosed in detail below in conjunction with the examples.

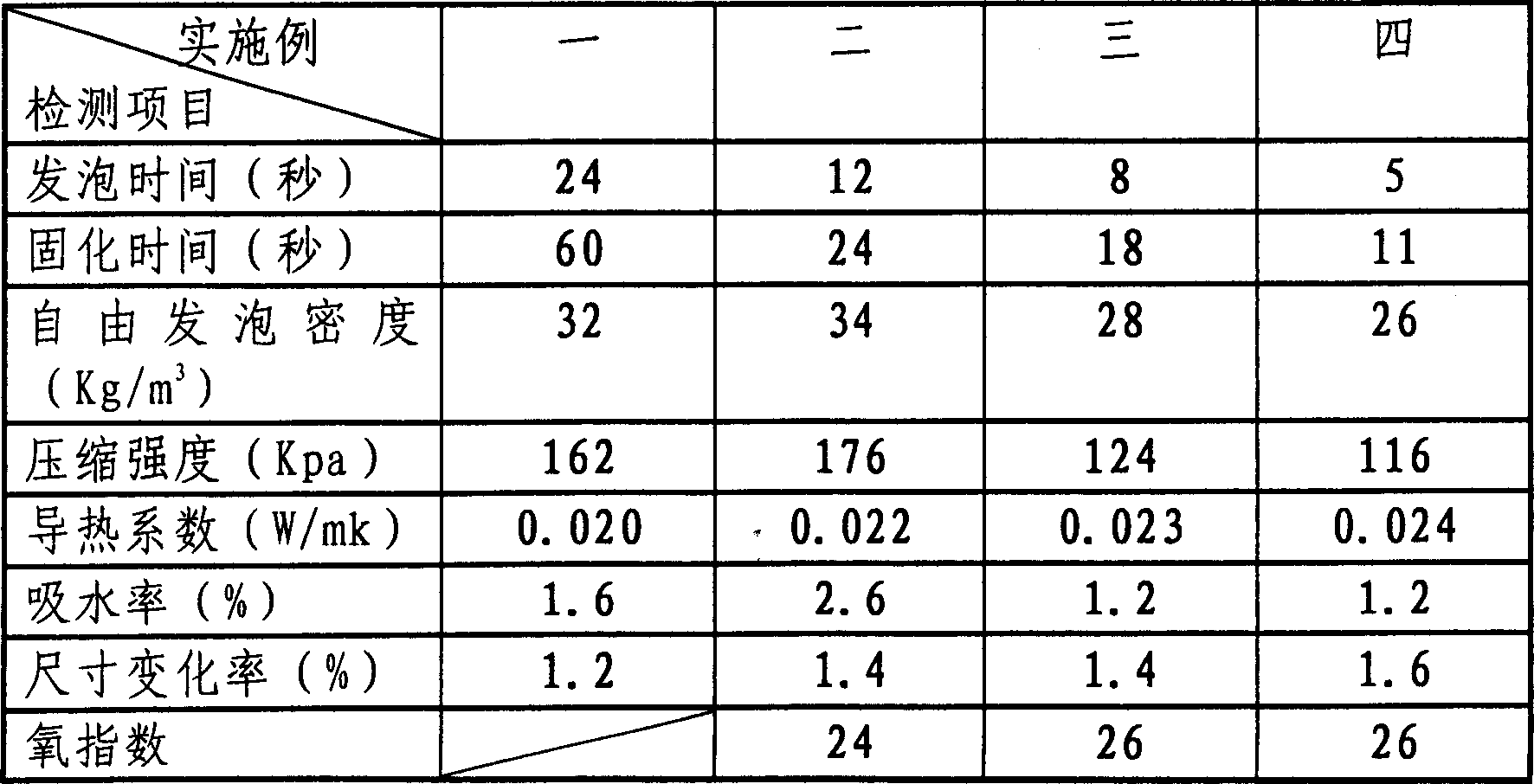

[0043] Table 1 is a formula example of the polyetherester polyurethane rigid foam blended with asphalt. Among them, four examples are prepared by reacting 100 parts of composite material A with polyisocyanate B whose isocyanate index is 105.

[0044] Table 2 is the performance index of the four embodiments corresponding to Table 1.

[0045] Table 1

[0046]

[0047] Table 2

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com