Integrated milling-rutter

A kind of milling cutter and integral technology, which is applied in the direction of milling cutter, milling machine equipment, manufacturing tools, etc., can solve the problems of not being able to meet the needs of finishing machining, burrs on the workpiece plate, and affecting the sharpness of the cutting edge, etc., so as to achieve better processing effect and sharper workpiece Improved surface finish and smooth chip discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

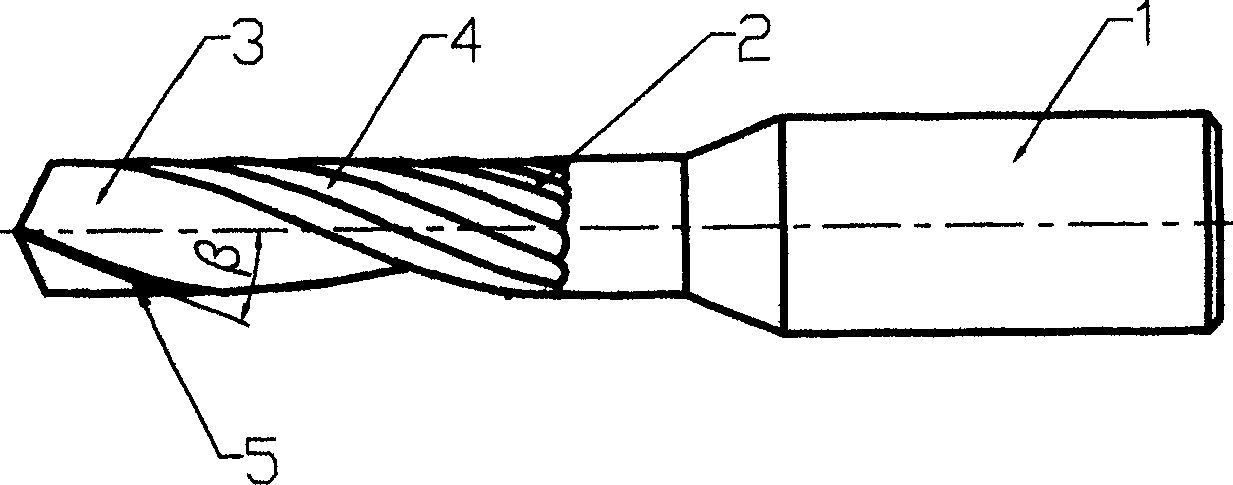

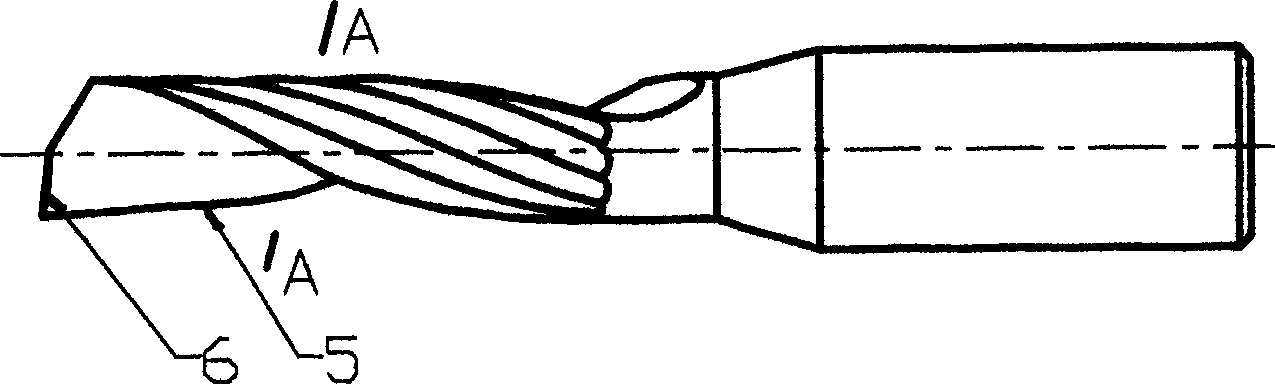

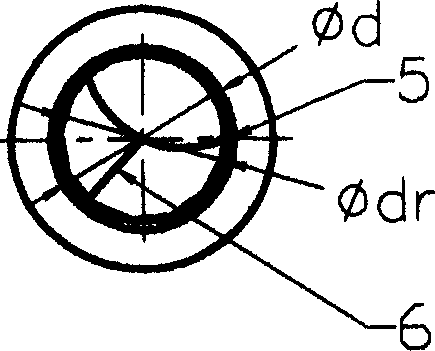

[0014] The integral milling cutter of the present invention is made up of shank part 1 and cutter body part 2, and cutter body part 2 is made of main cutting edge 5, minor cutting edge 6, rake face 3 and flank face 4 again, and main cutting edge 5 The helix angle is β, corresponding to the minor cutting edge 6, the rake face 3 is composed of spiral grooves, the flank face 4 has a width of b and a relief angle of a 1 A helical main flank 7 and multiple relief angles are a 2 And take the outer circle d where the back of the knife is located r It is composed of equal-width helical secondary flanks 8 that are circumscribed and evenly distributed along the circumference.

[0015] Concrete design parameters in the embodiment are as follows:

[0016] Example 1

Example 2

Example 3

Tool outer diameter (d)

1.5° -0.03

3.0° -0.03

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com