Method for preparing 2,4-toluene diamino menthyl formate

A technology of methyl toluene dicarbamate and diaminotoluene, applied in the preparation of 2, to achieve the effect of mild reaction conditions and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

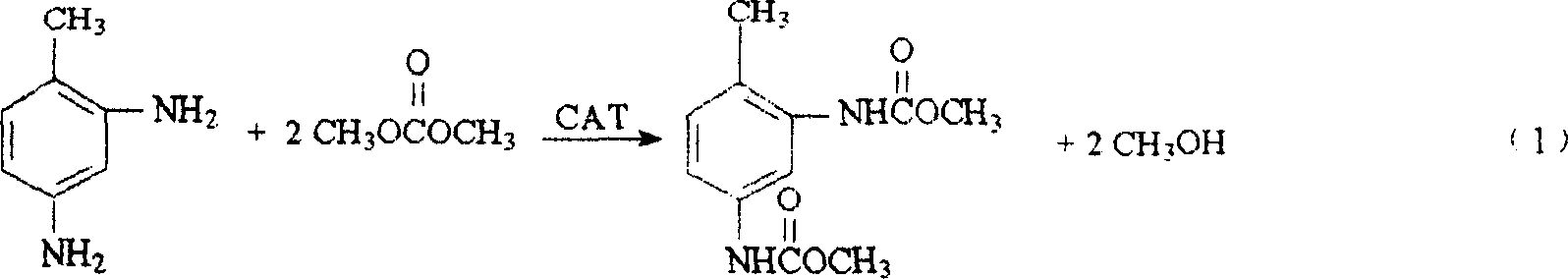

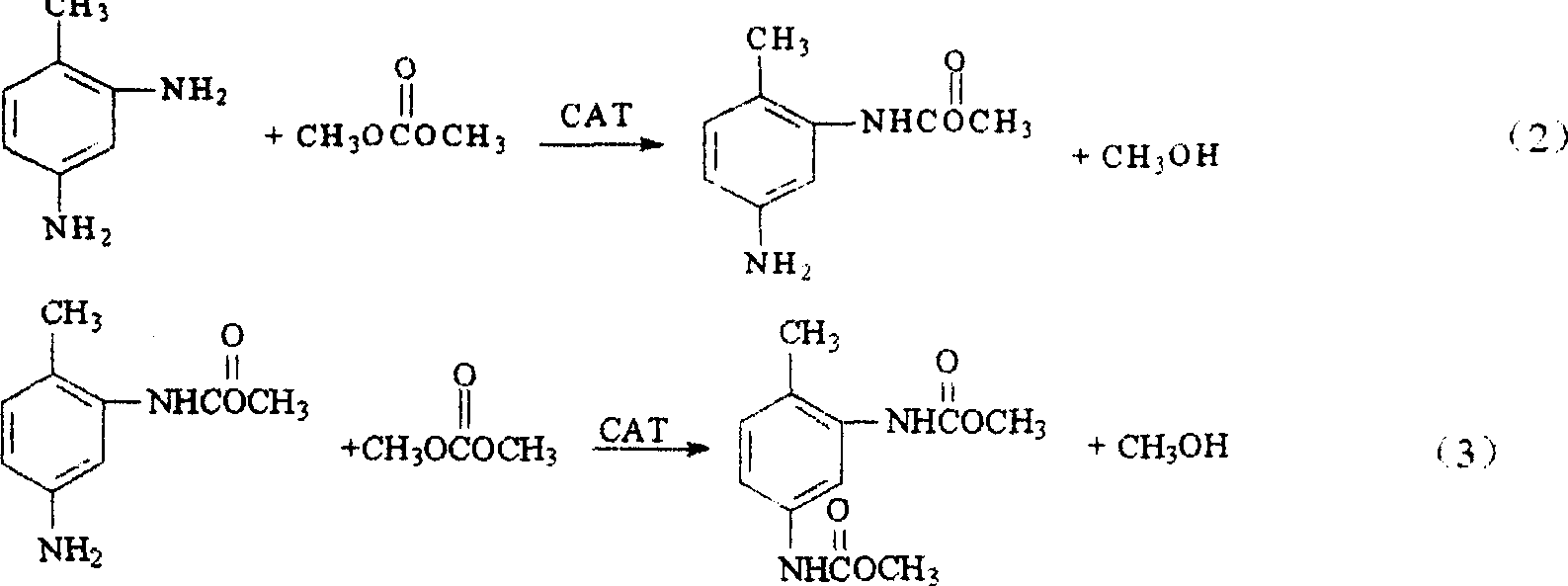

Method used

Image

Examples

Embodiment 1

[0049] Example 1: 5 g of TDA, 74 ml of DMC, and 0.9 g of zinc acetate were added to the reactor, the reactor was sealed, and the temperature was raised to 120° C. for 2 hours. Continue to raise the temperature to 150°C, and maintain it for 4 hours from the beginning of the temperature rise. Finally, the temperature was lowered to 120°C, and the temperature was maintained for 1 hour from the beginning of the temperature drop, and the reaction was completed. After discharge, filter at 90°C. The filtrate was distilled under reduced pressure, the vacuum degree of the reduced pressure distillation was 7-12mmHg, and the temperature was controlled at 40°C. 9.85 g of product was obtained. The product purity is 95.88%, and the TDC yield is 96.90%.

Embodiment 2

[0050] Example 2: 5 g of TDA, 74 ml of DMC, and 0.6 g of dehydrated zinc acetate were added to the reaction kettle, the reaction kettle was sealed, and the temperature was raised to 110° C. for 3 hours. Continue to raise the temperature to 160°C, and maintain it for 4 hours from the start of the temperature rise, and the reaction ends. After discharge, filter at 70°C. The filtrate was distilled under reduced pressure, the vacuum degree of the reduced pressure distillation was 7-12mmHg, and the temperature was controlled at 50°C. The product 9.72g was obtained. The product purity is 96.8%, and the TDC yield is 96.54%.

Embodiment 3

[0051] Example 3: 5 g of TDA, 55.5 ml of DMC, and 1.0 g of dehydrated zinc acetate were added to the reaction kettle, the reaction kettle was sealed, and the temperature was raised to 120° C. for 2 hours. Continue to raise the temperature to 170°C, and maintain it for 3 hours from the beginning of the temperature rise. Finally, the temperature was lowered to 140°C and maintained for 2 hours from the beginning of cooling. The reaction is over. After discharge, filter at 90°C. The filtrate was distilled under reduced pressure, the vacuum degree of the reduced pressure distillation was 7-12mmHg, and the temperature was controlled at 50°C. The product 9.78g was obtained. The product purity is 98.1%, and the TDC yield is 98.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com