Cyclic fluidizing dry flue desurlfurizing and duct collecting process by electric bag dust collector

A technology of dry flue gas desulfurization and bag filter, which is applied to chemical instruments and methods, separation methods, and separation of dispersed particles. Affect the dust removal effect of the dust removal system, etc., to avoid a sharp increase in the concentration of fine particles, increase the concentration of desulfurizer particles, and improve the efficiency of desulfurization reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

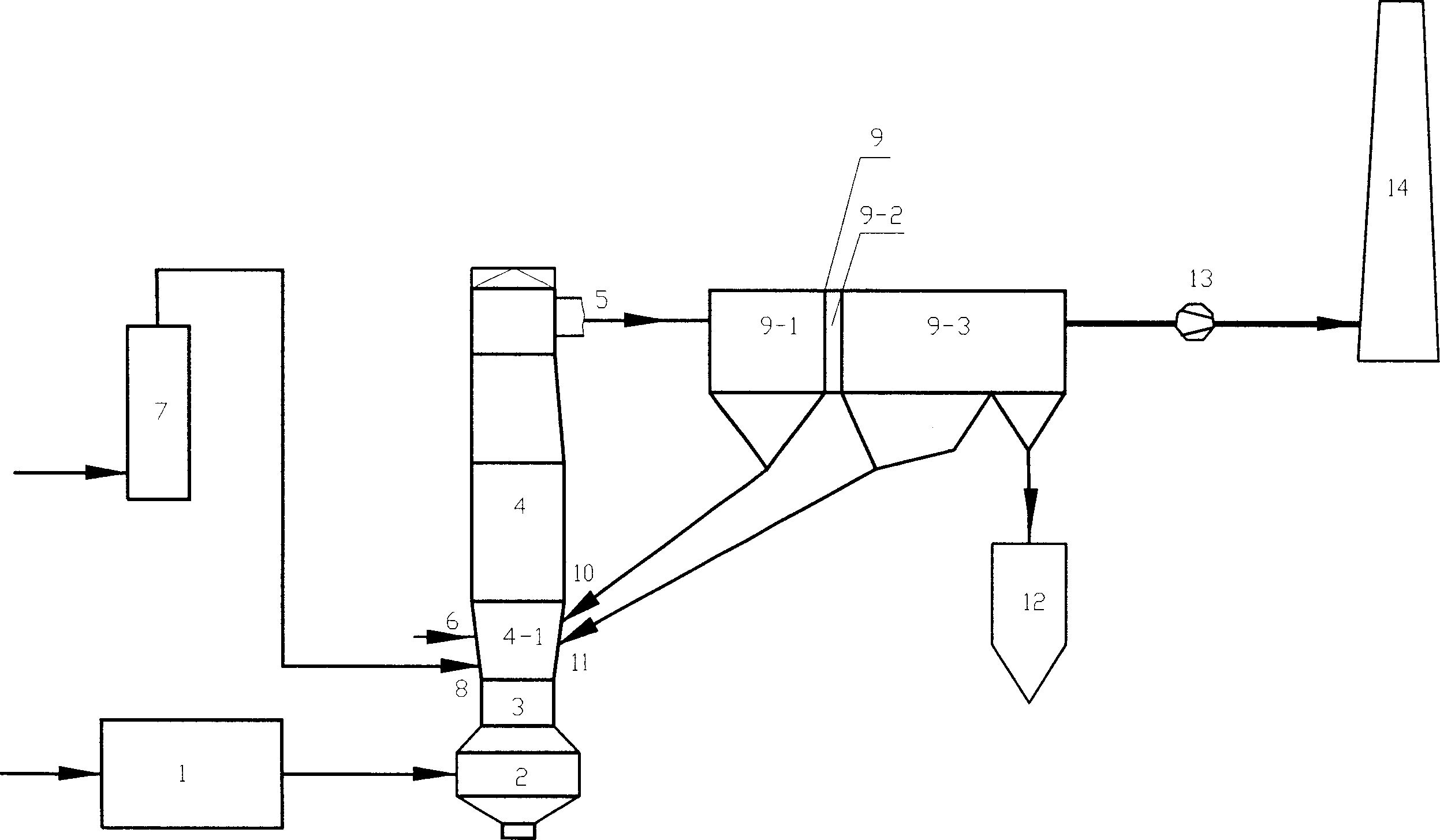

[0025] The separation of external desulfurization particles in the present invention adopts the electric bag dust removal separation method combining high-voltage electrostatic dust removal and bag dust removal, that is, the electric bag dust collector includes an electrostatic dust removal area and a bag dust removal area, and a grounding grid-like metal device is arranged between the two. The grid-shaped metal device adopts a porous plate with a hole diameter of 20-150mm, and an opening rate of 30%-60%.

[0026] Both the electrostatic dust removal area and the bag dust removal area carry out recirculation of desulfurization agent particles. The design value of the total separation efficiency of the electrostatic precipitator area is 70% to 95%. It mainly collects dust with a particle size between 3 and 25 μm. The separation efficiency for particles above 5 μm should reach 98%, and all the separated particles are collected. And sent back to the desulfurization tower, continue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com