Preparing method for chain superfine hydrofil

An ultra-fine calcium carbonate, chain technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of increased aspect ratio, unfavorable production efficiency, etc., to achieve the effect of non-toxic raw materials and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

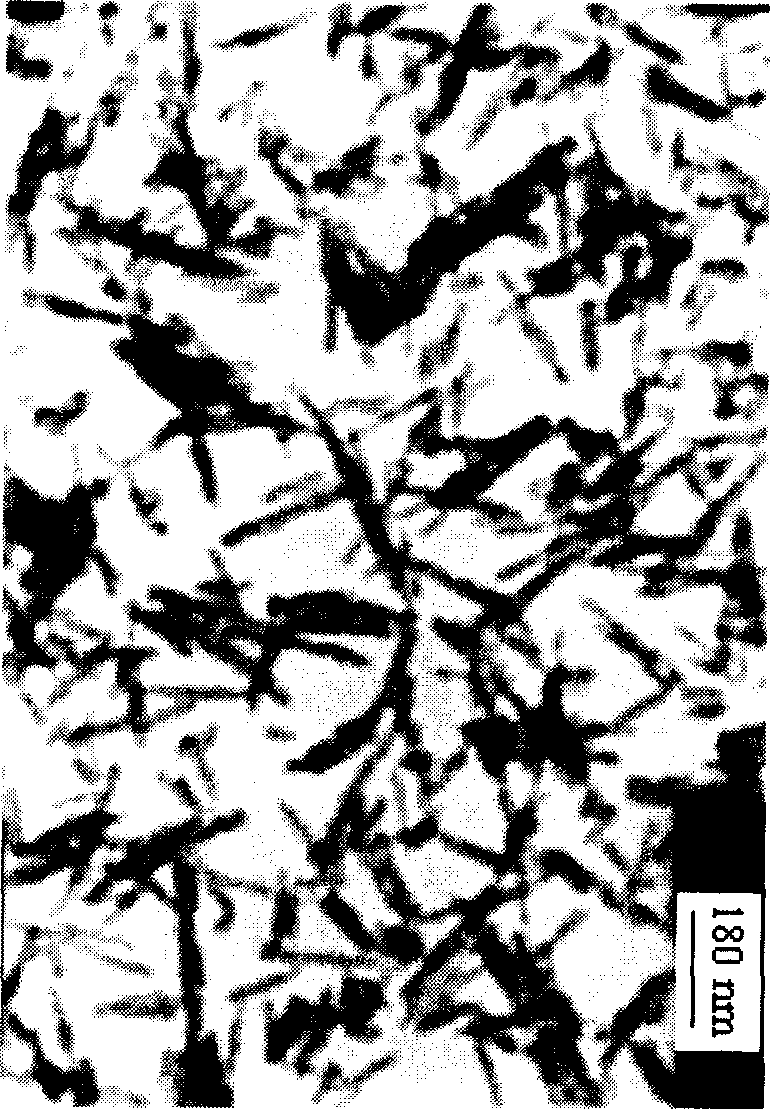

[0014] The prepared solid content is 5gCaO / 100mlH 2 O milk of lime 100ml, control the temperature at 23°C, before the reaction starts, dissolve 0.34g of EDTA2Na in 10ml of water, add to the reaction system, stir for 40min and then feed CO at a flow rate of 65-70mL / min 2 Gas, add 4ml of aqueous solution containing 0.055g PVP dispersant to the reaction system when the reaction is carried out to 15min, add 0.025g / nL CaCl when the reaction is carried out to 40min 2 2 mL of aqueous solution, and the reaction was completed when the pH was 6-7. XRD analysis showed that the obtained CaCO 3 For the calcite phase. After drying at 100°C, chain-like ultrafine calcium carbonate is obtained, and the transmission electron microscope photo is as follows: figure 1 As shown, its axial dimension is about 20 nm, and its aspect ratio is about 11:1.

Embodiment 2

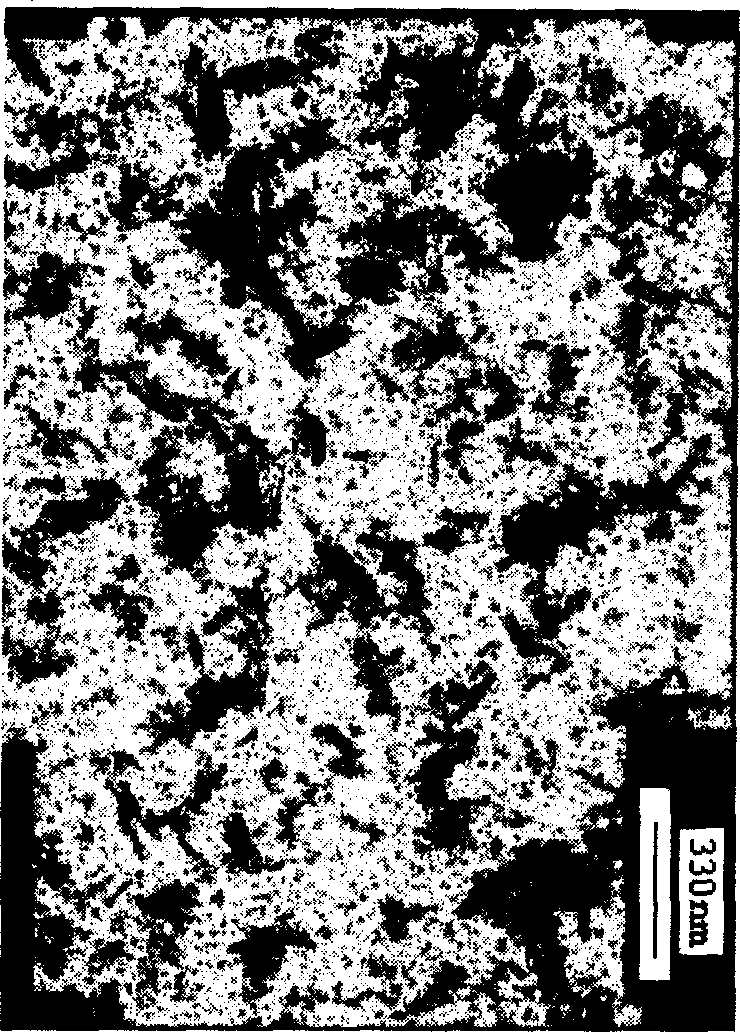

[0020] The prepared solid content is 5gCaO / 100mlH 2 O milk of lime 100ml, control the temperature at 23°C, before the reaction starts, dissolve 0.34g of EDTA2Na in 10ml of water, add to the reaction system, stir for 40min and then feed CO at a flow rate of 65-70mL / min 2 Gas, add 1ml of AE0-3 dispersant 1ml when the reaction is 15min, add 0.025g / mL CaCl when the reaction is 40min 2 2 mL of aqueous solution, and the reaction was completed when the pH was 6-7. After drying at 100°C, chain-like ultrafine calcium carbonate is obtained, with an axial dimension of about 30nm and an aspect ratio of about 10:1, but its dispersion effect is not as good as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com