Alloy type temp fuse and wire for temp fuse element

A technology of alloy type and fuse, which is applied in the direction of electrical components, fuse manufacturing, metal processing equipment, etc., can solve the problem of not being able to fully meet the working temperature of 130 ° C ~ 170 ° C, and achieve high capacity and reduce resistance efficiency, miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

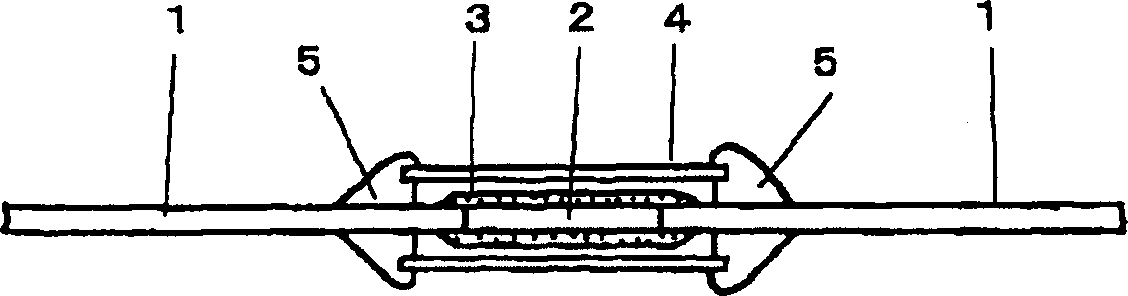

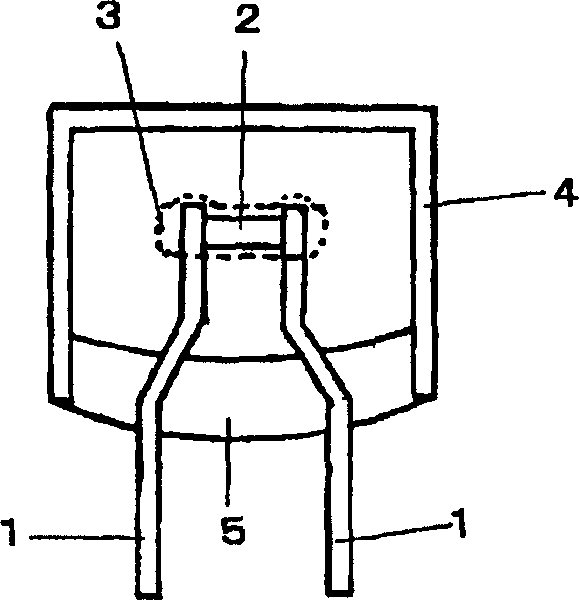

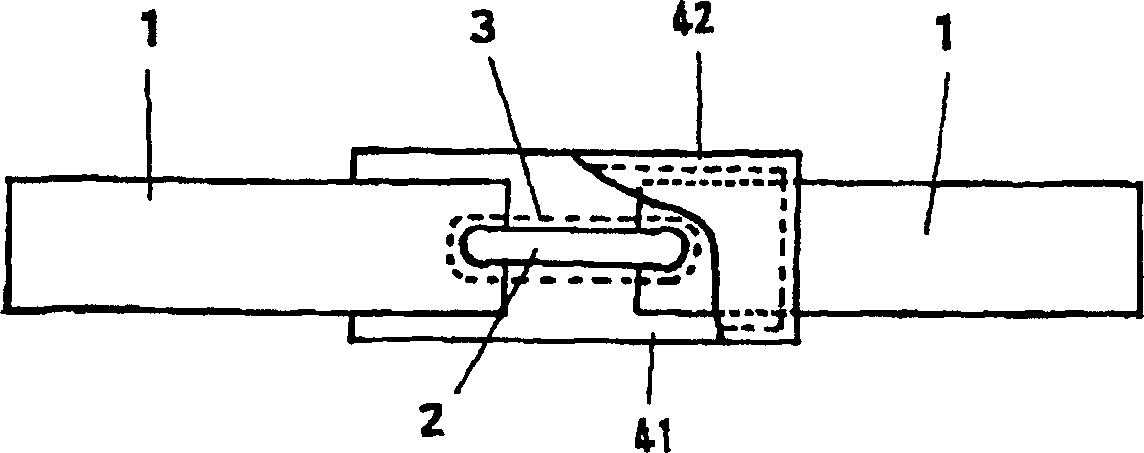

Image

Examples

Embodiment 1

[0078] The alloy-type temperature fuse of the cylindrical shell type has a fuse element whose composition is 48% Sn, 2% In, and Bi as the remainder.

[0079] It works in the above-mentioned overload charging, but it cannot work with the destruction. Regarding the insulation stability after this work, the lead conductors can withstand 2×rated voltage (500V) for 1 minute, and the lead conductor-outside of the cylindrical shell can withstand 2×rated voltage +1000V (1500V) for 1 minute, And when the DC voltage value is 2× rated voltage (500V), the insulation resistance between the lead conductors is 0.2MΩ or more, and the insulation resistance between the lead conductors and the outer surface of the cylindrical case is 0.2MΩ or more, then the insulation stability is ○.

[0080] When the temperature fuse is working, the temperature of the fuse element is 135°C, and the liquidus temperature of the fuse element is 152°C (the element temperature is 17°C lower than the liquidus tempera...

Embodiment 2~5

[0085] For Example 1, except that the amount of Sn is changed as shown in Table 1, and the amount of Bi corresponding to the device is also changed, it is considered to be the same as that of Example 1.

[0086] In either example, similarly to Example 1, no damage occurred even when operating under overload charging, and the insulation stability after overload operation was evaluated as ◯.

[0087] And, obviously, in which embodiment, the element temperature during operation is also lower than the liquidus temperature (11°C-13°C lower), and the fuse element is cut off in the solid-liquid coexistence region. The reason why the insulation stability of the temperature fuse after operation is ○ without causing damage during overload charging is presumed to be because the fuse element is cut off in a wide solid-liquid coexistence area, because the operation There are very few arcs shortly thereafter, and it is difficult to cause a local and rapid temperature rise, so the pressure r...

Embodiment 2 Embodiment 3 Embodiment 4

[0091] Example 2 Example 3 Example 4 Example 5

[0092] Sn(%) 44 53 62 70

[0093] In(%) 2 2 2 2

[0094] Bi(%) remaining remaining remaining remaining

[0095] Disruptive while working None None None None

[0096] Insulation stability after operation ○ ○ ○ ○

[0097] Liquidus temperature (°C) 144 156 167 178

[0098] Component temperature at work (°C) 132±1 143±2 152±3 162±3

[0099] Resistivity (μΩ·cm) 36 31 27 23

[0100] Wire drawing property ○ ○ ○ ○

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com