Excited quasi-molecule lamp

An excimer lamp, outer tube technology, applied in discharge lamps, electrical components, circuits, etc., can solve problems such as breakage, reduced lamp illumination, and reduced lamp life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

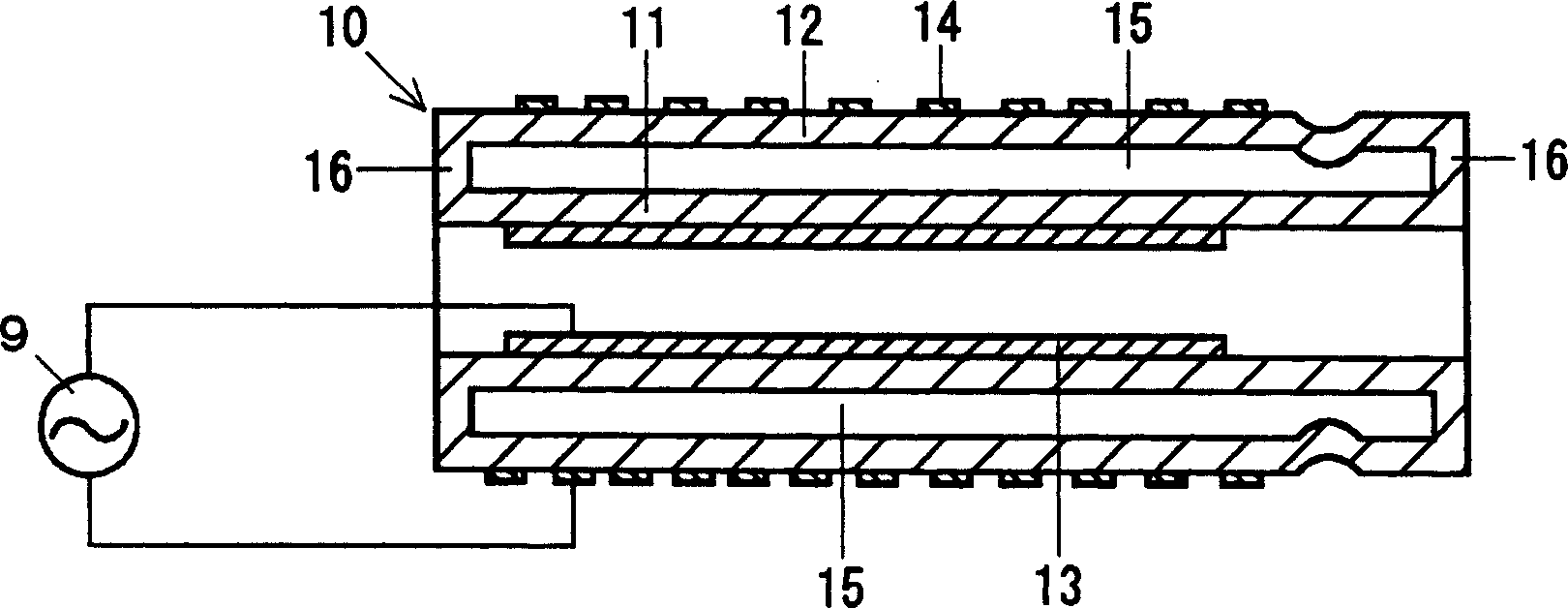

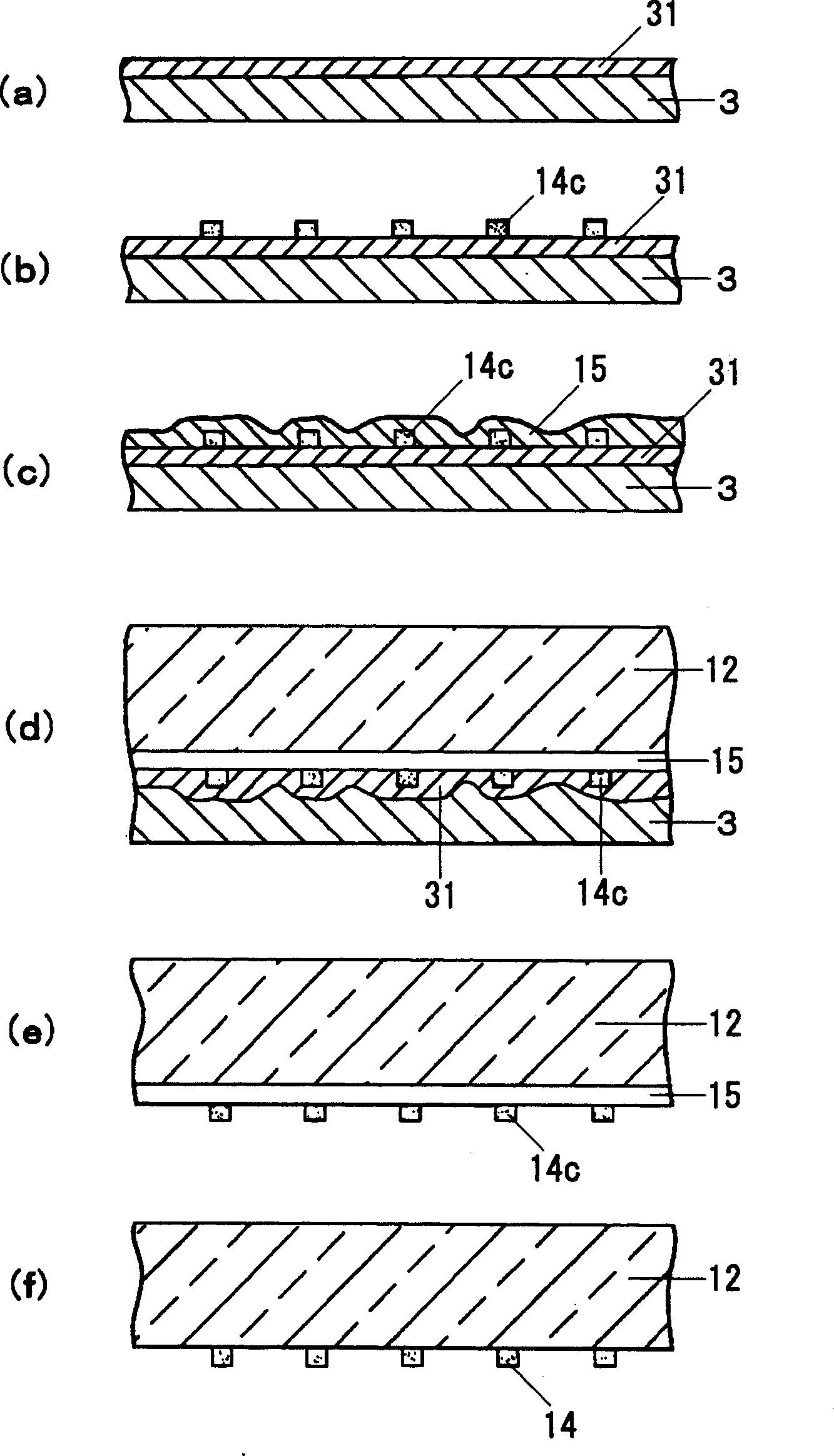

[0016] The configuration and operation of a preferred embodiment of the excimer lamp according to the present invention will be described below with reference to the drawings.

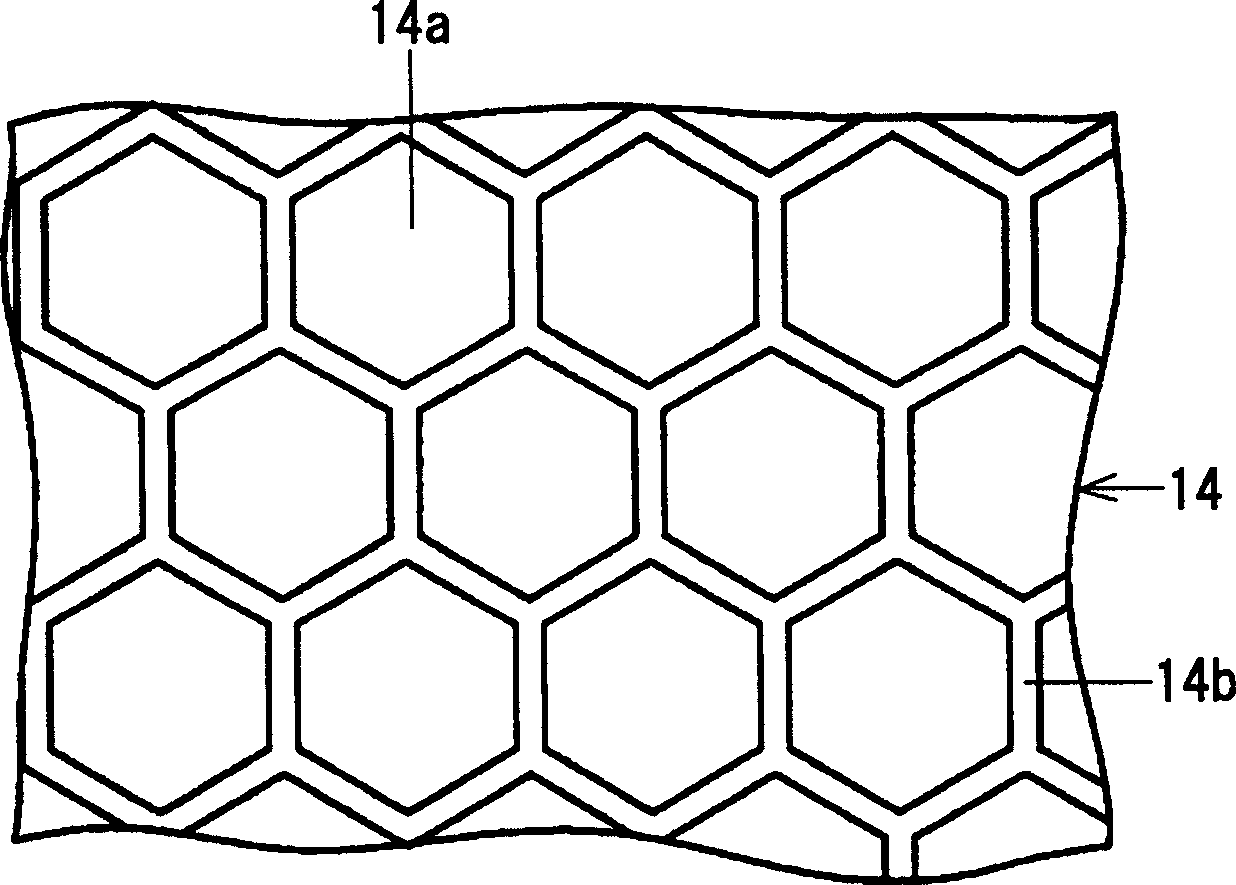

[0017] figure 1 is a longitudinal sectional view of an embodiment of an excimer lamp according to the present invention, figure 2 It is an enlarged view showing a part of the outer electrode of the excimer lamp. Such as figure 1 As shown, the excimer lamp includes: a discharge tube 10, which is composed of a coaxial inner tube 11 and an outer tube 12, the two ends of which are joined by a joint 16 to form a closed end; an inner electrode 13, which is arranged on the inner surface of the inner tube 11; and the outer electrode 14, which is provided on the outer surface of the outer tube.

[0018] By applying a high voltage from a high-voltage AC power supply 9 between the inner electrode 13 and the outer electrode 14, the discharge gas (rare gas such as argon, krypton, xenon, etc.) sealed in the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com