Continuous prepn. of amine

A technology of carboxamide and cyclopropylamine, applied in the preparation of organic compounds, rearrangement reaction preparation, chemical instruments and methods, etc., can solve problems such as difficult continuous mode, low space-time yield, and no method for Hoffman reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

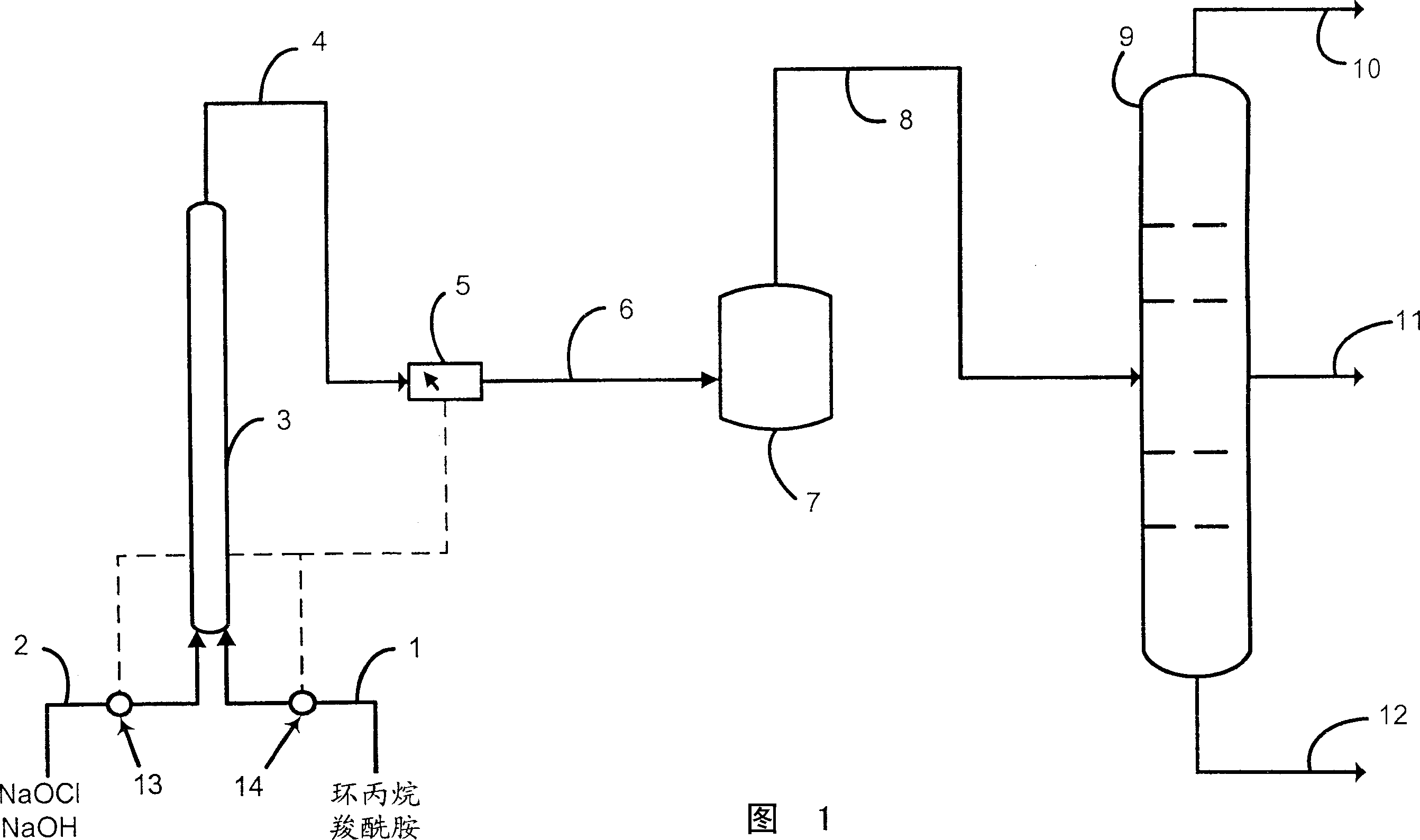

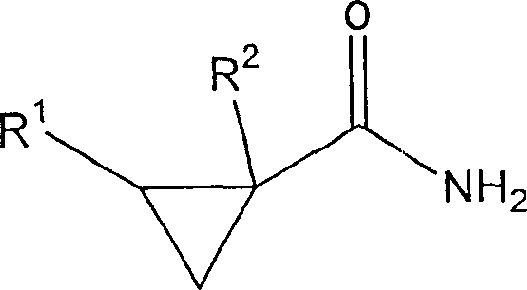

[0022] The present invention provides a continuous process for the preparation of amines utilizing the Hofmann reaction of carboxamides and alkaline hypohalites. We have found that by utilizing two reaction zones, measuring the concentration of at least one component of the first reaction mixture from the first reaction zone and using the measurement to control the flow of at least one reactant to the first reaction zone In such a way that the feed rate, thereby achieving the desired conversion or concentration of the reaction components, the Hofmann reaction can be performed continuously in an efficient and economical manner. The term "component" or "reaction component", as used herein, means any starting material, reactant, product, intermediate, present in a reaction mixture, in any process stream, or in any process equipment, solvents, or by-products. Non-limiting examples of components or reaction components that may be present in the first reaction mixture include: a so...

Embodiment

[0057] Example

[0058] 2 variable speed peristaltic pumps (Cole-Parmer U-77912-00, Cole-Parmer, Vernon Hills, IL) were connected by polytetrafluoroethylene (PTFE) hoses (with 4 mm PTEE tubing at the top of the reactor). Connect the outlet of the mixer to the mixer and use a 7.9 mm ID hose (LIS 17 C-FLEX Pipe, Cole-Parmer U-06424-25, Cole-Parmer, Vernon Hills, IL) was equipped with a continuous production unit for cyclopropylamine; the mixer consisted of a Y-shaped fitting of 8 mm (3 / 8 inch) OD glass , with a 2mm stirring rod inserted and held at the "Y" connection. The connection between the 4mm PTFE tubing and the 7.9mm ID tubing was completed using a short section of the 7.9mm ID tubing as filler between the 4mm PTFE tubing and the larger bore L / S 17 tubing. The mixer was magnetically stirred throughout the reaction and was connected to the first reactor with a minimum practicable length of 7.9 mm ID tubing. The first reactor representing a plug flow reactor consis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com