Heating roller, image heating apparatus, and image forming apparatus

A heating device and heating roller technology, applied in the field of heating rollers, can solve the problems of low mechanical durability of the heat generating layer, increase of excitation circuit cost, increase of preheating time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

[0035] attached Figure 5 Shown is a cross-sectional view of an example of an image forming apparatus according to the present invention in which an image heating device is used as a fixing device. The image heating device installed in the image forming apparatus according to Embodiment 1 is an electromagnetic induction heating device of a roll heating type. The following description is directed to the structure and operation of such a device.

[0036] Reference numeral 1 denotes an electrophotographic photoreceptor (hereinafter referred to as "photosensitive drum"). While the photosensitive drum 1 is driven at a predetermined peripheral speed in the direction indicated by the arrow, the surface of the photosensitive drum 1 is uniformly negatively charged by the charger 2 to reach a predetermined dark potential V0.

[0037] Reference numeral 3 denotes a laser beam scanner that outputs a time-series electrical digital pixel signal according to image information input from a h...

Embodiment I-1

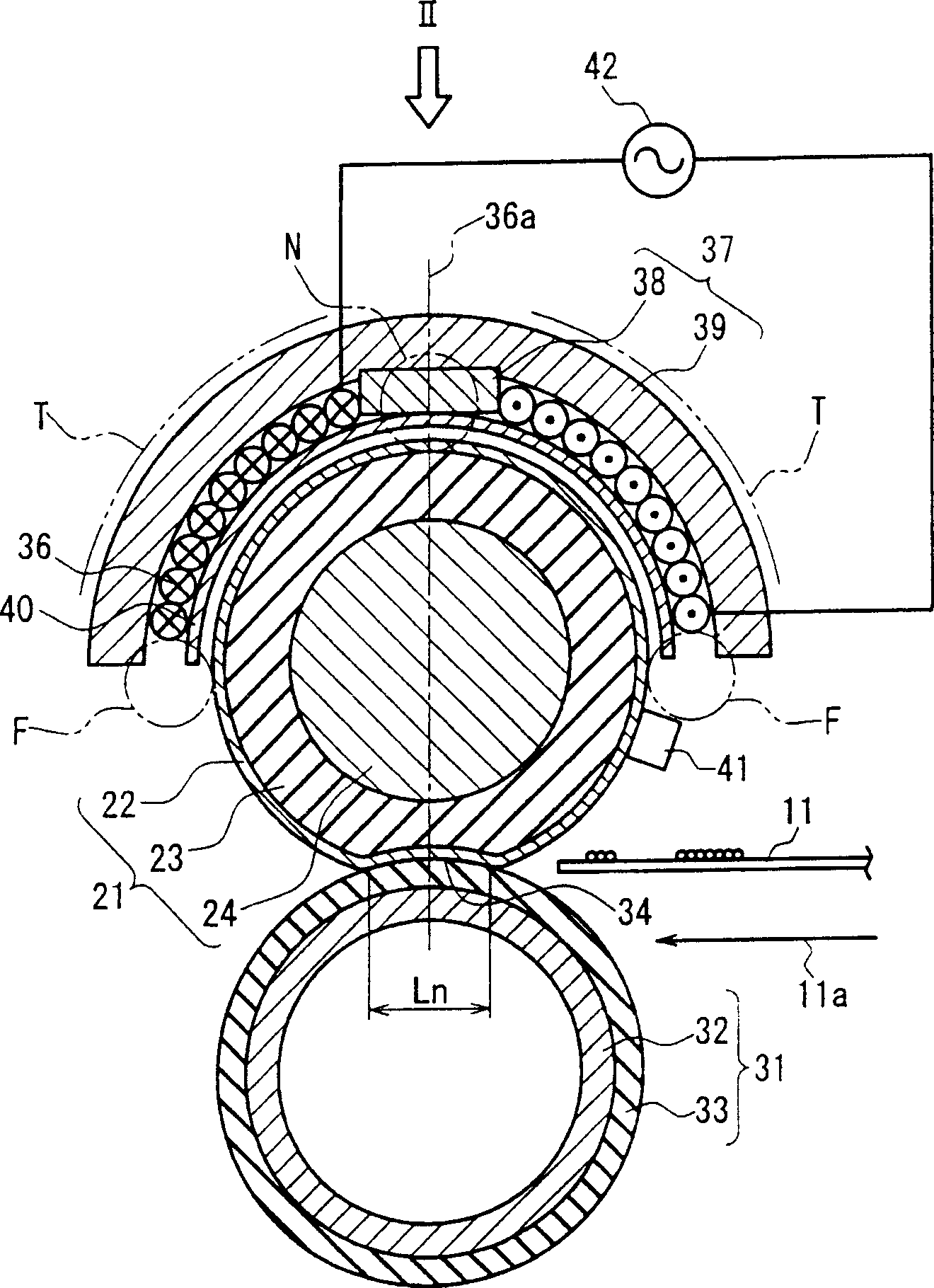

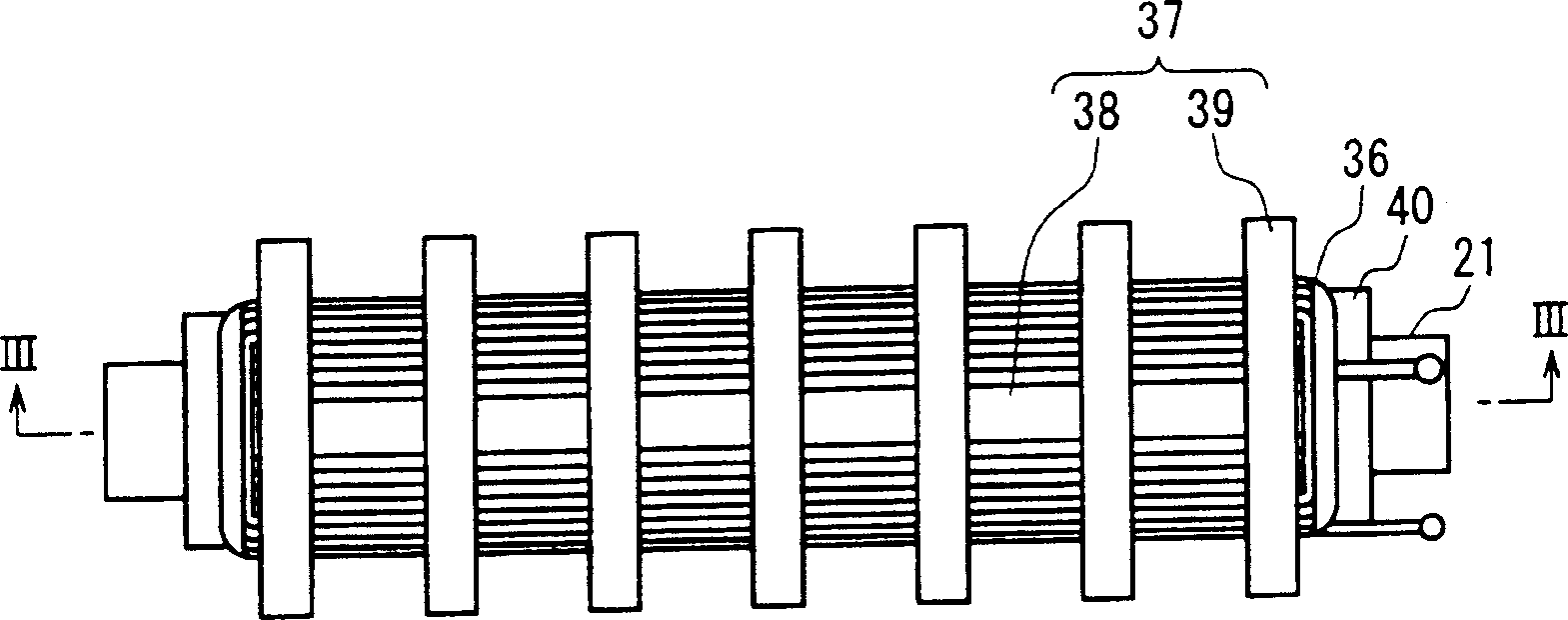

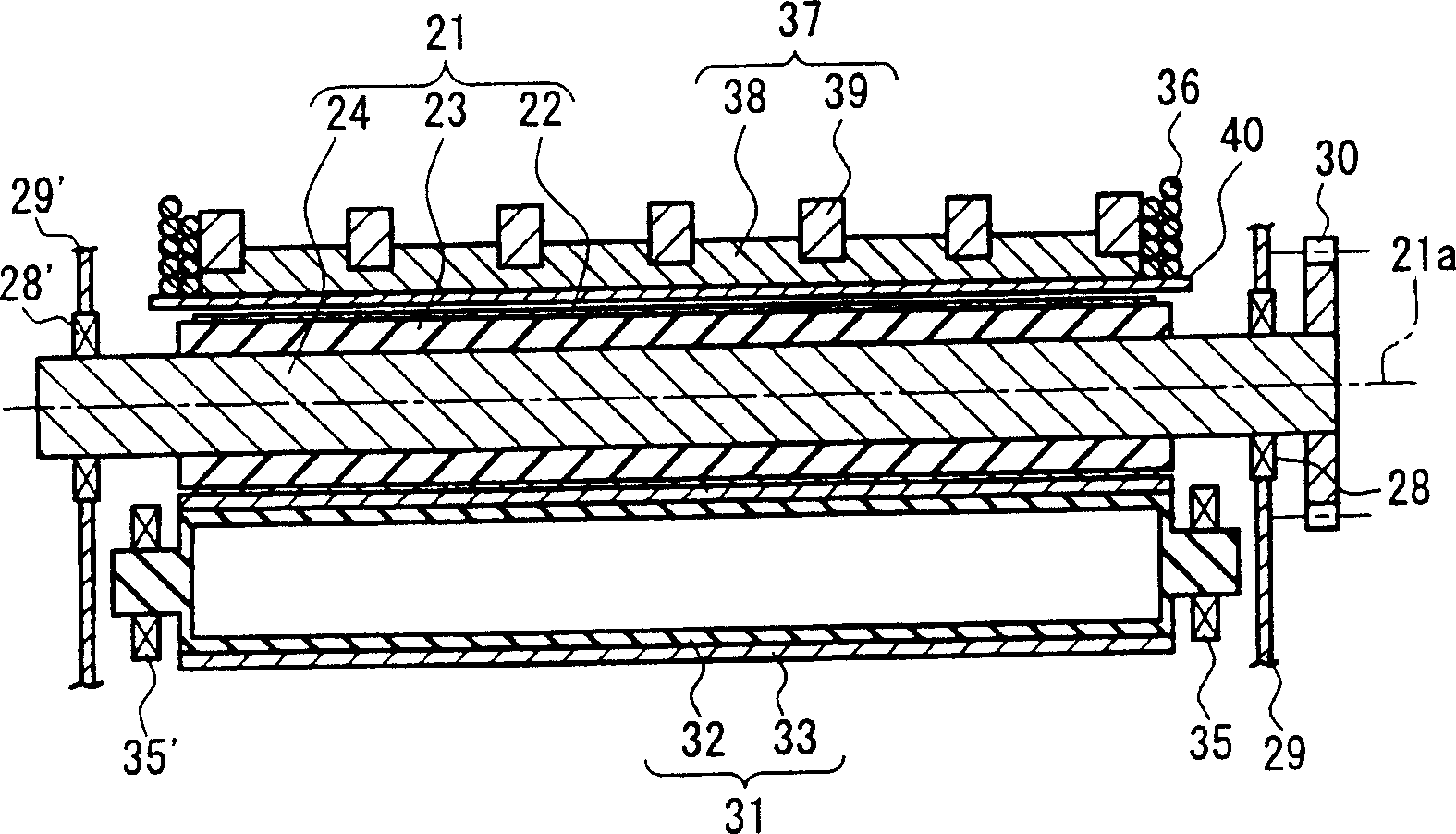

[0068] attached figure 1 Shown is a cross-sectional view of an image heating device used as a fixing device according to Embodiment I-1 of the present invention, which is used in the attached Figure 5 In the above image forming apparatus shown in . attached figure 2 shown from attached figure 1 Structural view of the excitation unit looking in the direction indicated by the arrow II. attached image 3 shown in the attached figure 2 A perspective sectional view taken on the line III-III (a plane including the rotation center axis 21a of the heating roller 21 and the winding center axis 36a of the excitation coil 36). attached Figure 4 Shown is a cross-sectional view of the layered structure of the surface layer portion of the heating roller 21 including the heat generating layer 22 .

[0069] Reference numeral 21 denotes a heating roller, which is composed of a heat generating layer 22 formed of a thin conductive material, a heat insulating layer 23 formed of a mat...

Embodiment I-2

[0112] Then refer to the attached Figure 7 ,8 and 9 describe the image heating device according to Embodiment I-2 as the fixing device. In Embodiment I-2, similar reference characters denote similar components having the same structure and performing the same functions as components in the image heating apparatus described according to Embodiment I-1, and their repetitions are omitted here. describe. In this embodiment, the squeeze roller 31, the exciting coil 36, the rear magnetic core 37, etc. have the same structure as those described according to the embodiment I-1.

[0113] In an example according to the present embodiment, as the heat generating layer 22 , a 40 μm-thick endless strip-shaped material of non-magnetic stainless steel SUS304 formed by plastic processing is used. Although SUS304 is basically non-magnetic, plastic processing still produces magnetism in SUS304. In addition, SUS304 has excellent durability against mechanical deformation as its basic characte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com