Staining method for cashmere fibre or cashmere fabric

A technology of cashmere fiber and dyeing method, which is applied in the field of textile dyeing and finishing, can solve the problems of increased dye usage and cost, and achieve the effects of increased permeability, deep dyeing, and bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Cut the cashmere fabric into a sample of 5cm×5cm, put it into the low-temperature plasma reaction chamber, and vacuumize it. When the pressure in the reaction chamber reaches 4Pa, start to introduce air to balance the vacuum degree in the reaction chamber at 53Pa, and then treat the electrodes placed in the processing chamber. A voltage was applied, glow discharge was performed, and each discharge treatment was performed for 90 seconds with a power of 100 W.

[0024] The cashmere fabric after the above-mentioned low-temperature air plasma treatment was dyed according to the following conditions.

[0025] Dye Recipe % (o.w.f. to fabric weight)

[0026] Weak acid red B 2

[0027] Pingping plus O-10 0.3

[0028] Acetic acid 2

[0029] pH 5

[0030] Bath ratio 1:50

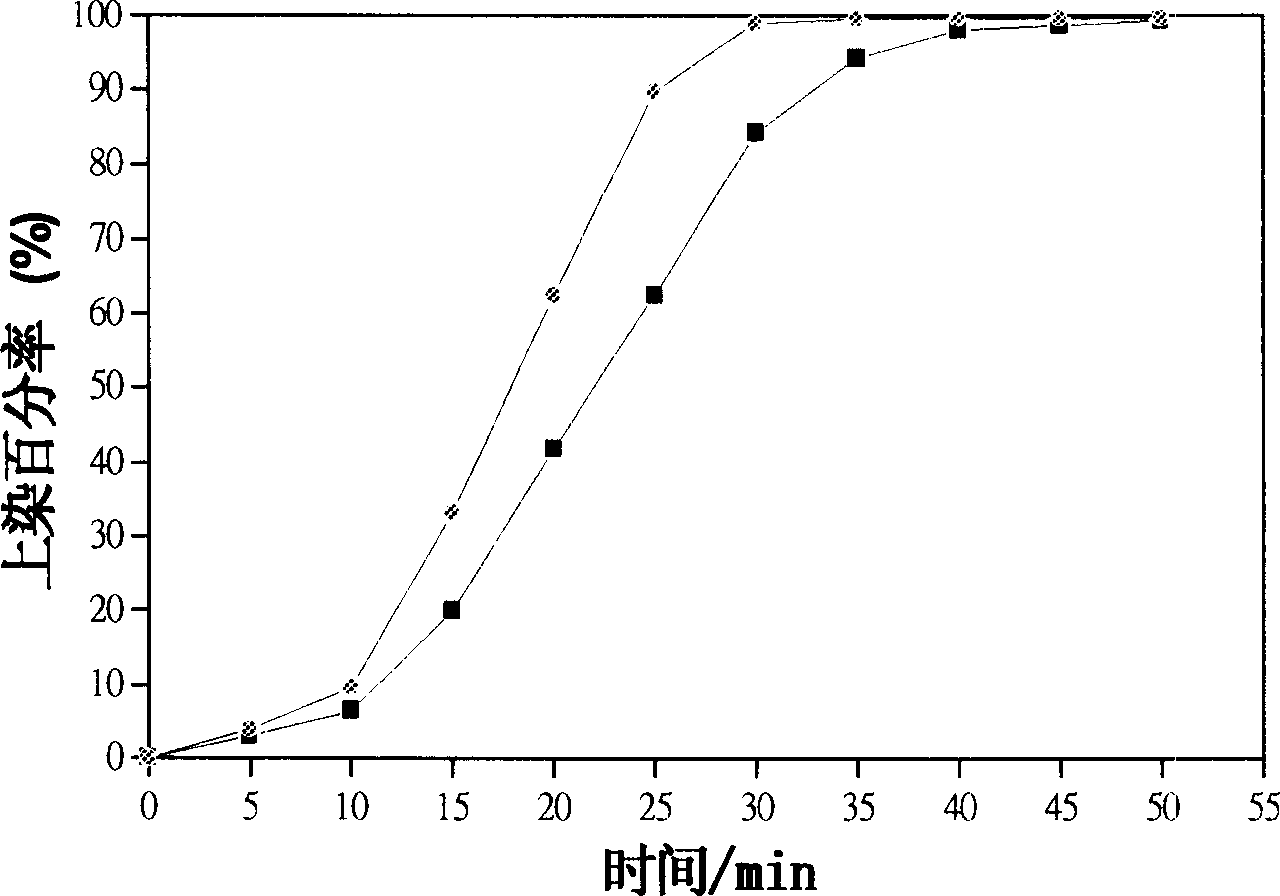

[0031] Dyeing process: Add the cloth sample when the above-mentioned prepared dyeing bath is heated to 30°C, and heat up at a rate of 2°C / min. After boiling, keep it for 20 minutes, take out the cloth samp...

Embodiment 2

[0037] Cut the cashmere fabric into a sample of 5cm×5cm, put it into the low-temperature plasma reaction chamber, and vacuumize it. When the pressure in the reaction chamber reaches 7Pa, start to introduce oxygen to balance the vacuum degree in the reaction chamber at 67Pa, and then treat the electrodes placed in the processing chamber. Voltage is applied to perform glow discharge, and discharge treatment is performed for 300s with 100W power.

[0038] The cashmere fabric after the above-mentioned low-temperature air plasma treatment was dyed according to the following conditions.

[0039] Dye Recipe % (o.w.f. to fabric weight)

[0040] Lanna free and easy red 2B 2

[0041] ABIG SET 3

[0042] Acetic acid 2

[0043] pH 4.5

[0044] Bath ratio 1:30

[0045] Dyeing process: Add the cloth sample when the above-mentioned prepared dyeing bath is heated to 30°C, and heat up at a rate of 2°C / min. After boiling, keep it for 20 minutes, take out the cloth sample and rinse it twice...

Embodiment 3

[0054] Cut the cashmere fabric into a sample of 5cm×5cm, put it into the low-temperature plasma reaction chamber, and vacuumize it. When the pressure in the reaction chamber reaches 10Pa, start to introduce argon gas to balance the vacuum degree in the reaction chamber at 160Pa. Voltage is applied to the electrodes to perform glow discharge, and discharge treatment is performed for 300 seconds with 20W power.

[0055] The cashmere after the above-mentioned low-temperature plasma treatment was put into ammonia water with a concentration of 5% by weight and a bath ratio of 1:20, heated to 30° C. and kept for 20 minutes. After taking it out, perform low-temperature staining under the following conditions.

[0056] Dye Recipe % (o.w.f. to fabric weight)

[0057] Lanna free and easy yellow 4GN 2

[0058] ABIG SET 3

[0059] Acetic acid 2

[0060] pH 4.5

[0061] Bath ratio 1:30

[0062] Dyeing process: When the dyeing bath prepared above is heated to 35°C, add the cloth sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge power | aaaaa | aaaaa |

| Discharge power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com