Making process of electrolytic copper foil with great high-temperature elongation

A technology of electrolytic copper foil and manufacturing method, which is applied in electrolytic process, electroforming, etc., can solve problems such as increased production cost, increased sensitivity to chlorine pollution, troubles in the use of electrolytic copper foil, etc., achieves good surface quality, overcomes thermal cracking or is a distorted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

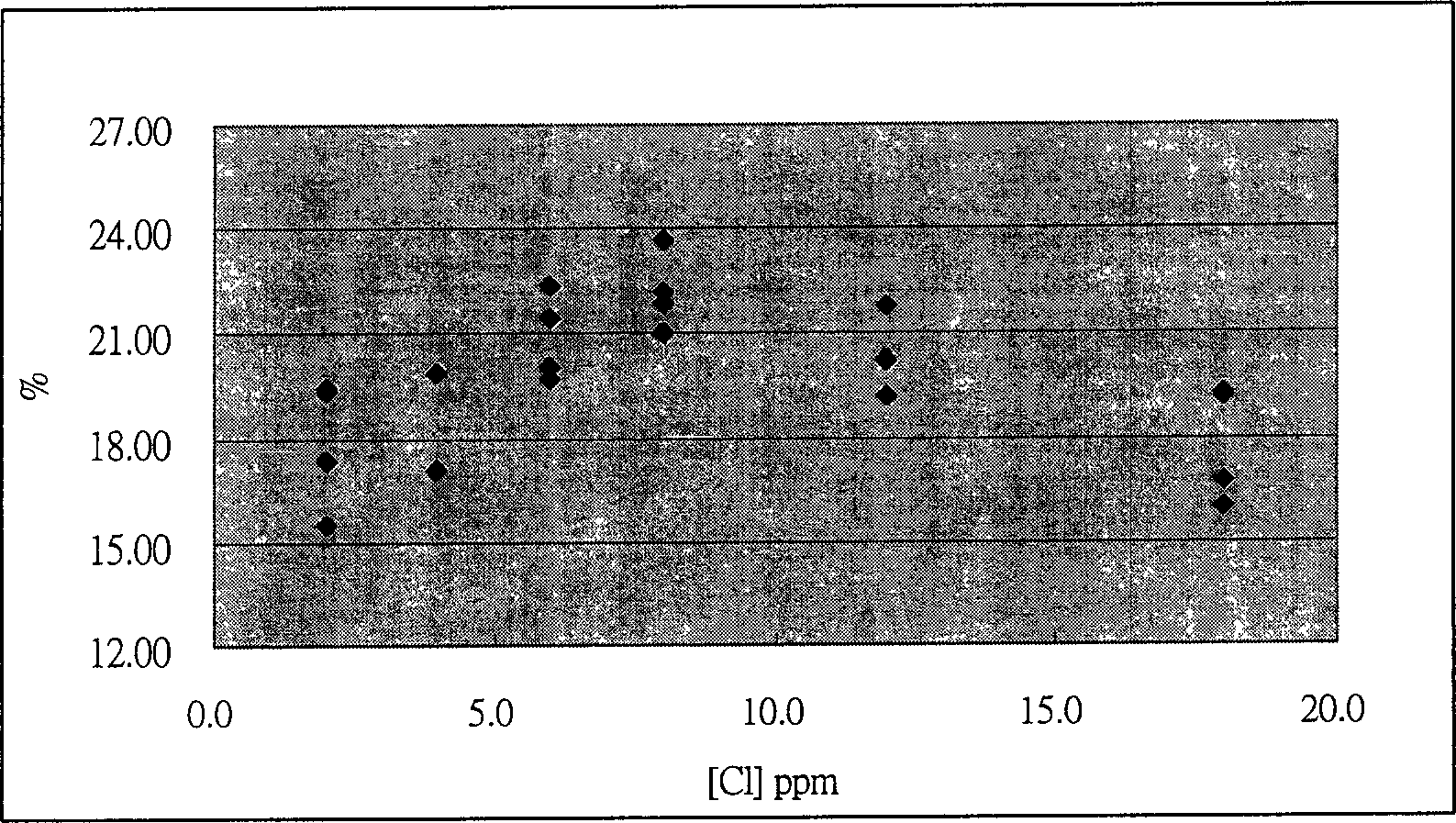

[0024] Because of considering that the concentration of gelatin in the plating solution needed to increase the high-temperature elongation of the electrolytic copper foil is relatively low, contrary to the higher demand for the gelatin concentration required to increase the surface quality of the electrolytic copper foil, the present invention first increases the concentration of gelatin Control in the range of 0-1.5ppm (lower than the traditional concentration of 2-10ppm). As for the surface quality of the electrolytic copper foil that is reduced due to this adjustment, it should be combined with an acidic copper sulfate plating solution with the following conditions to reduce the concentration of chloride ions to below 20ppm (6-12ppm is the best). It can be produced with good surface quality (RzD-3515%, HTE-35μm>20%; HTE: High TemperatureElongation-high temperature elongation) of electrolytic copper foil.

[0025] Acidic copper sulfate plating solution formula:

[0026] Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com