High-purity benzoyl chloride synthesizing process

A technology of benzoyl chloride and synthesis process, applied in the field of high-purity benzoyl chloride synthesis technology, can solve the problems of complicated purification steps, highly toxic phosgene, low process yield and the like, and achieves low cost, easy control and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

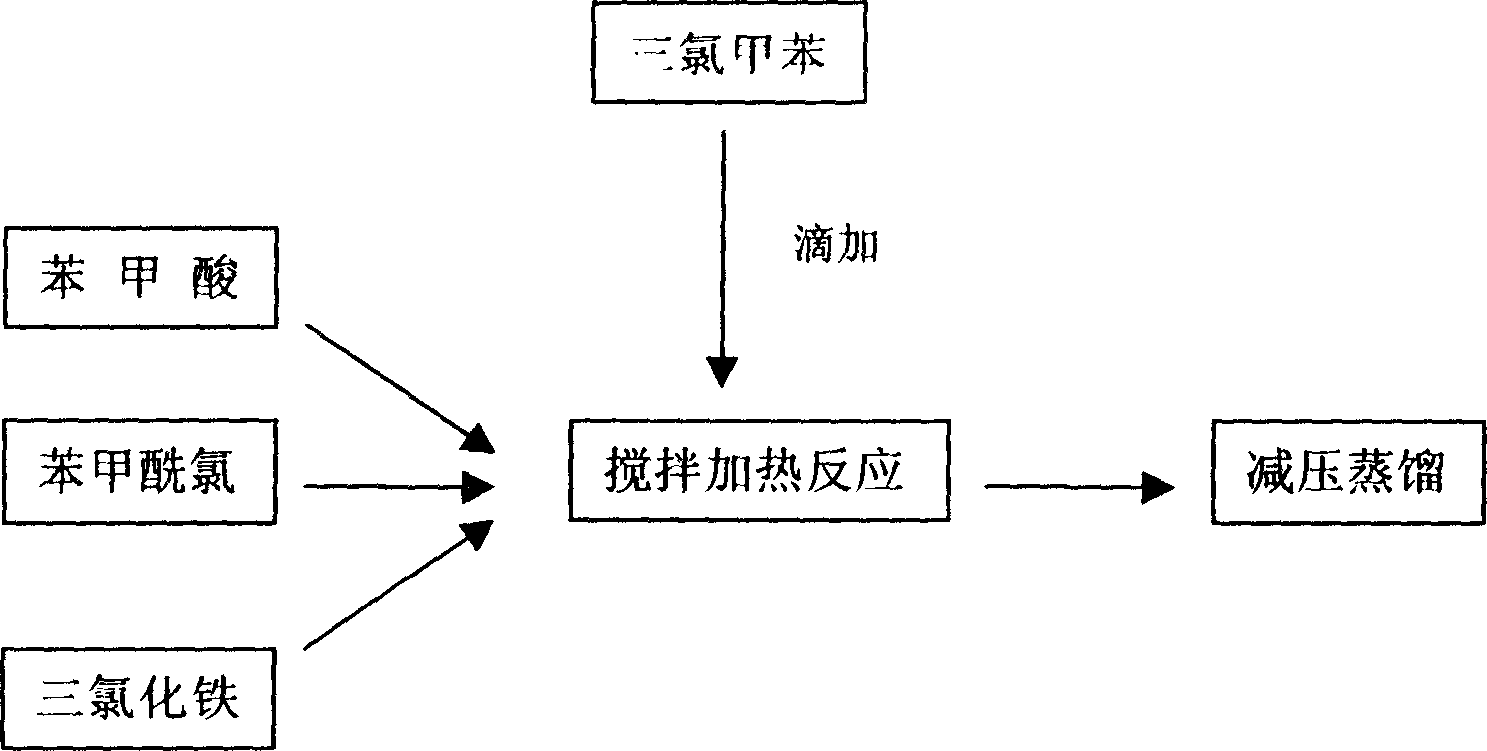

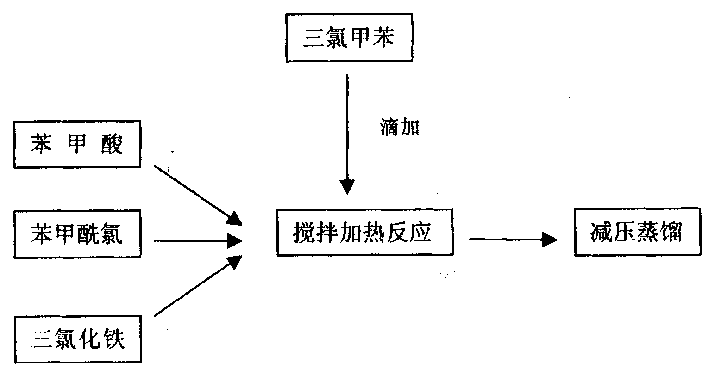

[0017] A kind of benzoyl chloride synthesis technology is to use benzoyl chloride as solvent, under the action of catalyst iron trichloride, benzoic acid and trichlorotoluene are co-heated to generate benzoyl chloride.

[0018] The proportioning of materials of benzoyl chloride synthesis technique is:

[0019] Benzoic acid 600kg

[0020] Trichlorotoluene 980kg

[0021] Solvent benzoyl chloride 600kg

[0022] Catalyst Ferric chloride 1.8kg

[0023] Benzoyl chloride synthetic technique is:

[0024] 1) Put 600kg of benzoyl chloride, 600kg of benzoic acid and 1.8kg of powdered anhydrous ferric chloride into a 2000L reaction pot by weight, stir and heat to 60°C, add 980kg of trichlorotoluene dropwise, and the dropping temperature is maintained at 50 -60°C, the dropping time is about 2-3 hours, and react at 60-80°C until no bubbles are generated after the dropping;

[0025] 2) above-mentioned solution is pumped into distillation pot, and underpressure distillation makes benzoyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com