Piling vessel with pile rotating unit

A technology for a piling ship and a piling frame, which is applied in the field of shipbuilding, can solve the problems affecting the productivity improvement of the piling ship and the proportion of working hours, and achieve the effects of reducing the number of ship transfers, high work efficiency and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

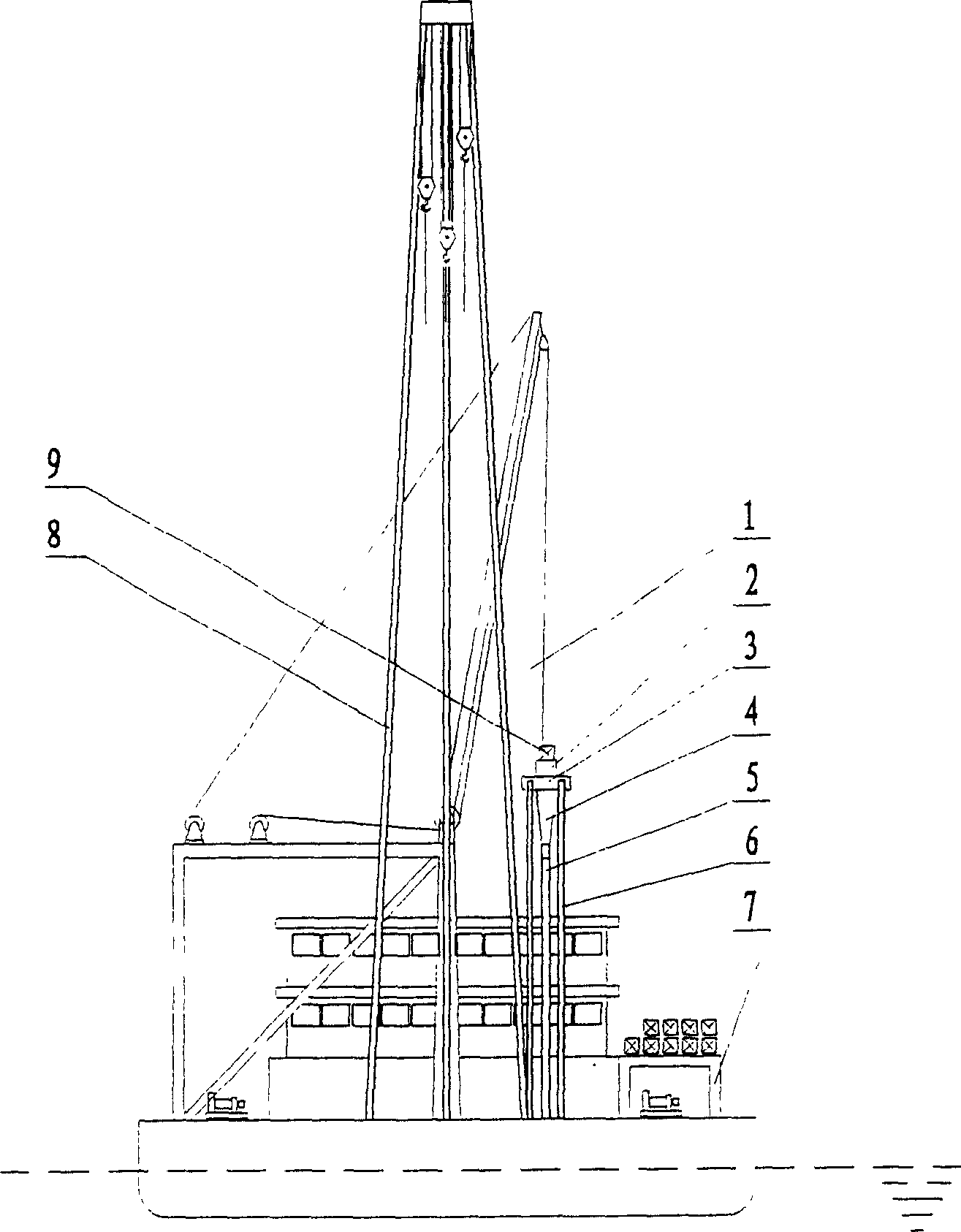

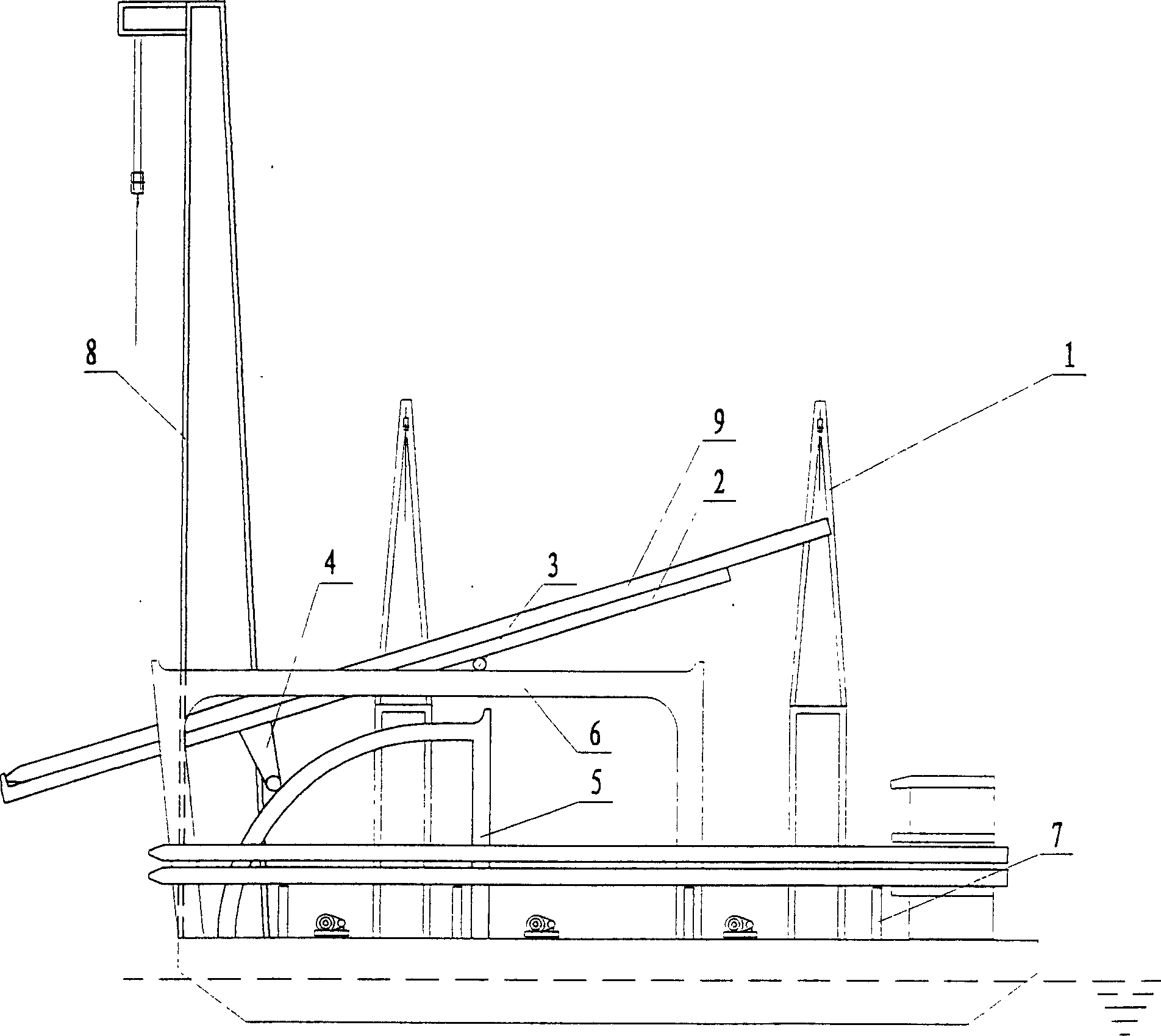

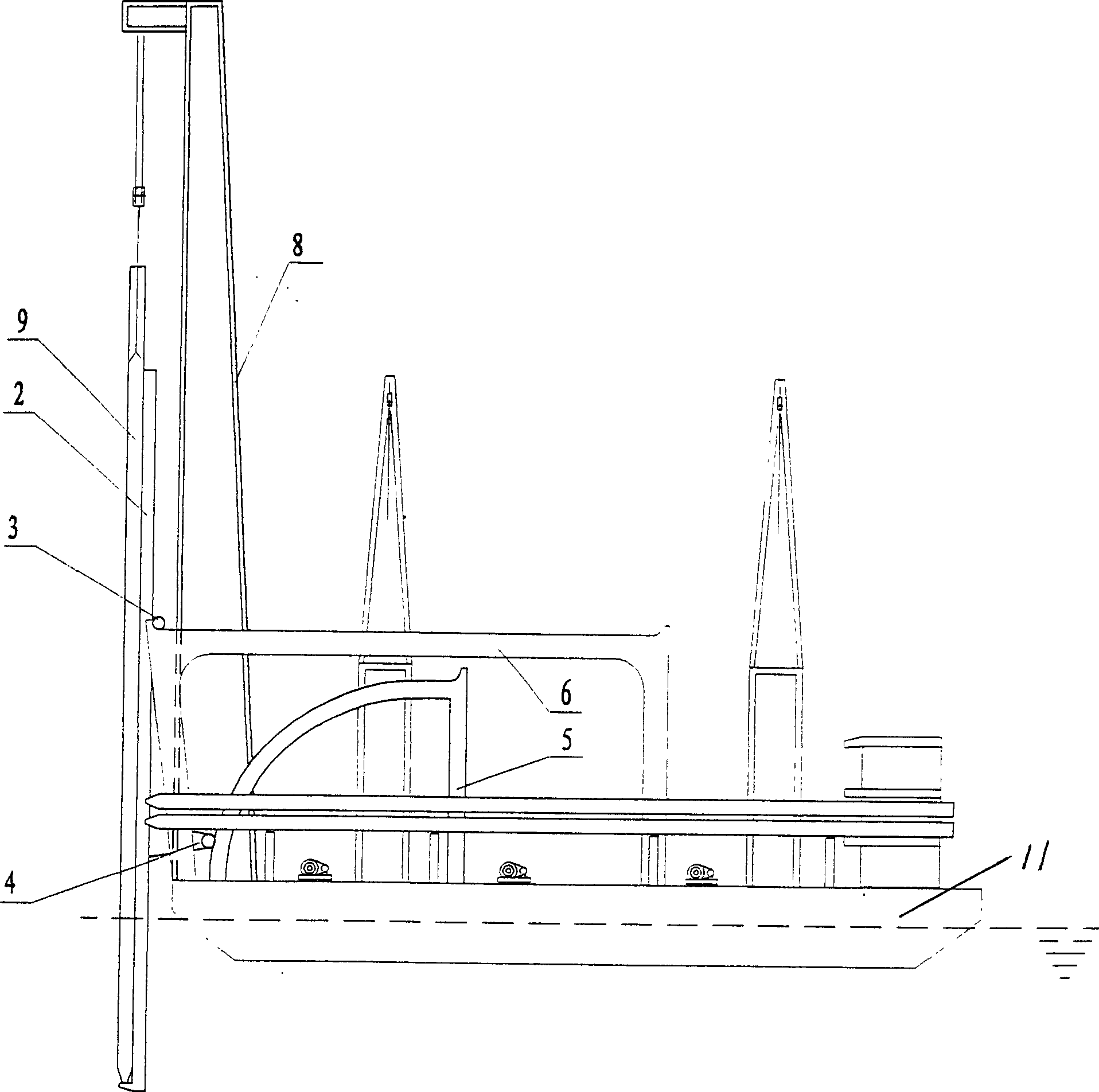

[0012] A piling ship with a piling device, which mainly includes a hull 11, a power system installed in the hull and a luffing pile driving frame 8 installed on the hull. It is different from the prior art in that: the hull 11 is equipped with a piling Device 12, pile storage bracket 7 and pile hanging crane 1, implementing transfer pile device 12 has two outer slideway frames 6, an inner slideway frame 5 and a pile holder frame 2, and the inner slideway frame 5 is placed between two outer slideway frames. Between the slideway frames 6, the pile support frame 2 is placed on the inner slideway frame 5, and there is a leg 4 near the front end at the back of the pile support frame 2, and the support leg 4 rests on the slideway surface of the inner slideway frame 5 There is a crossbeam 3 near the rear end at the back of the pile holder 2, and the crossbeam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com