Seabed sand filling rotary distributing device

A rotary, distributor technology, applied in fillings, safety devices, mining equipment, etc., can solve problems such as turbulent flow, damage to seabed ecology, and the inability of large-scale production of seabed non-metallic minerals to improve production efficiency, The effect of reducing the number of boat transfers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

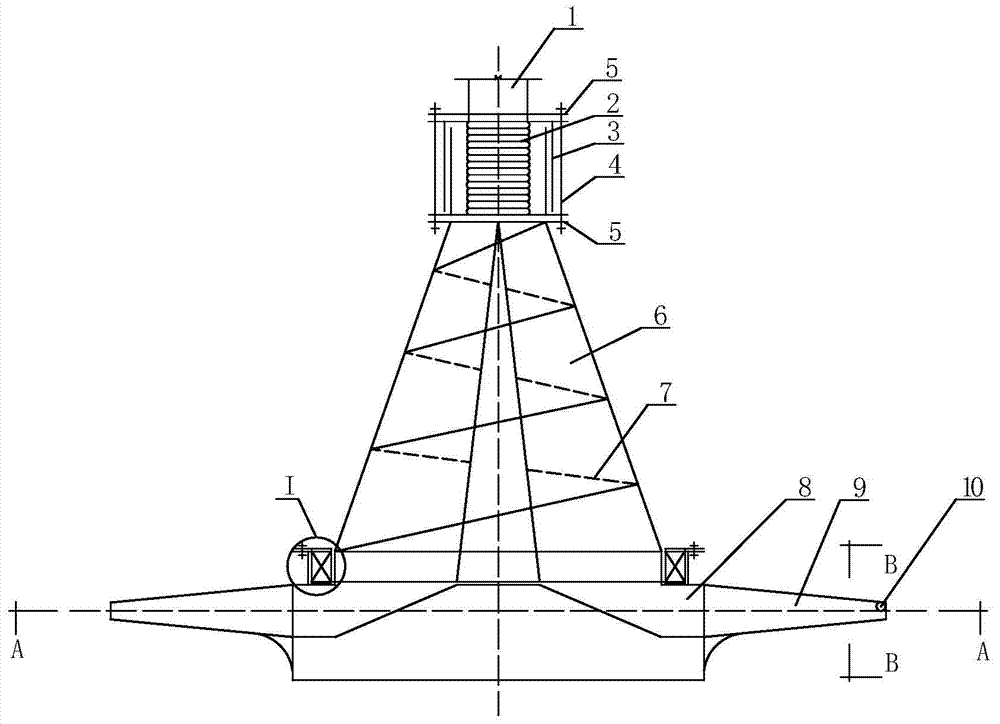

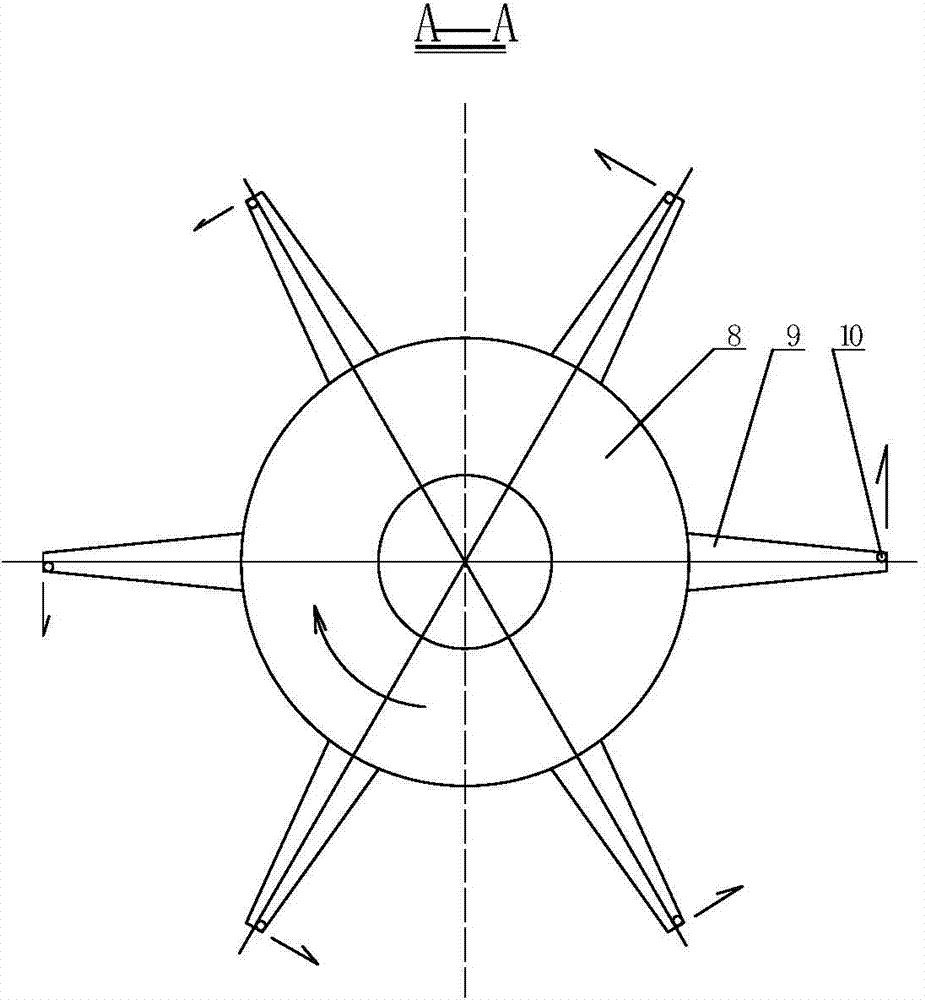

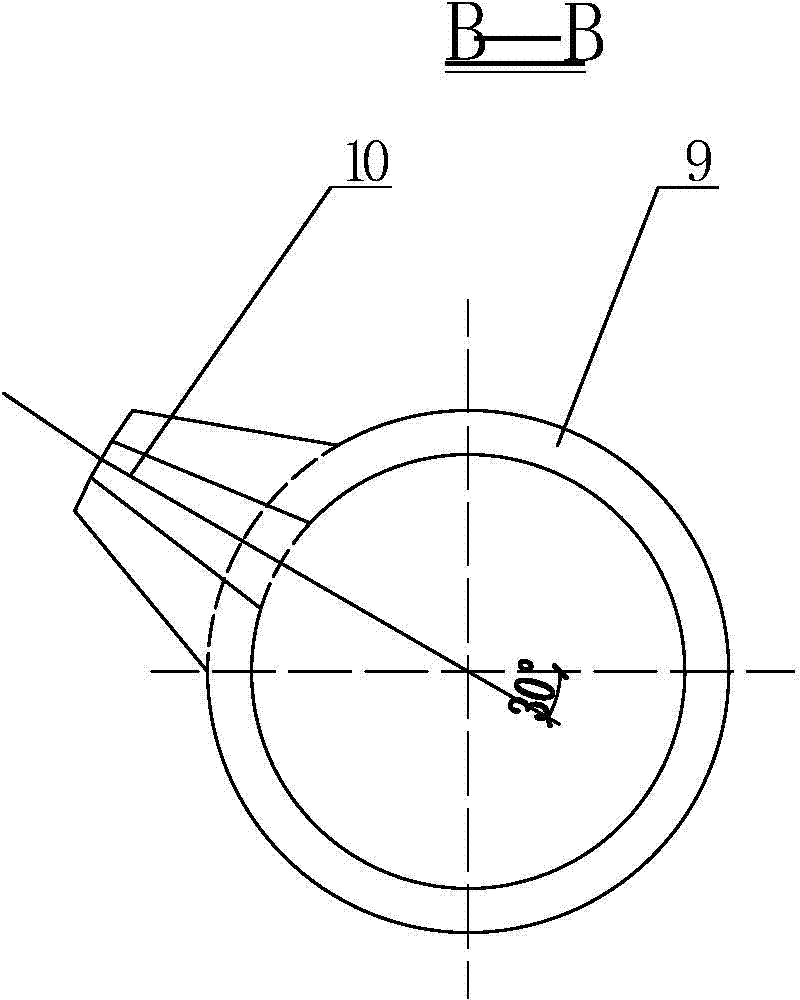

[0025] See figure 1 , is a structural schematic diagram of the present invention, the seabed sand filling rotary distributor of the present invention, including a corrugated rubber hose 2 connected sequentially from top to bottom, a spiral descending channel for slurry cylinder 6 and a floating disc rotary jet launcher 8, the The corrugated rubber hose 2 is flexibly connected with the upper external slurry delivery pipe 1 and the lower spiral descending channel feeding tube 6 through the sleeve type connection device, and the spiral descending channel feeding tube 6 is connected with the floating disc type rotary jet launcher 8 There is a sleeve connection between them.

[0026] The sleeve-type connection device is composed of a sleeve 3, a connecting flange 5 and a length-limiting tie rod 4. The sleeve 3 is set on the outside of the corrugated r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com