High gloss ink-jet recording paper for photographic printing

An inkjet recording, high gloss technology, applied in printing, copying/marking methods, coating, etc., can solve problems such as failure to be practical and difficult surface gloss of cast-coated paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

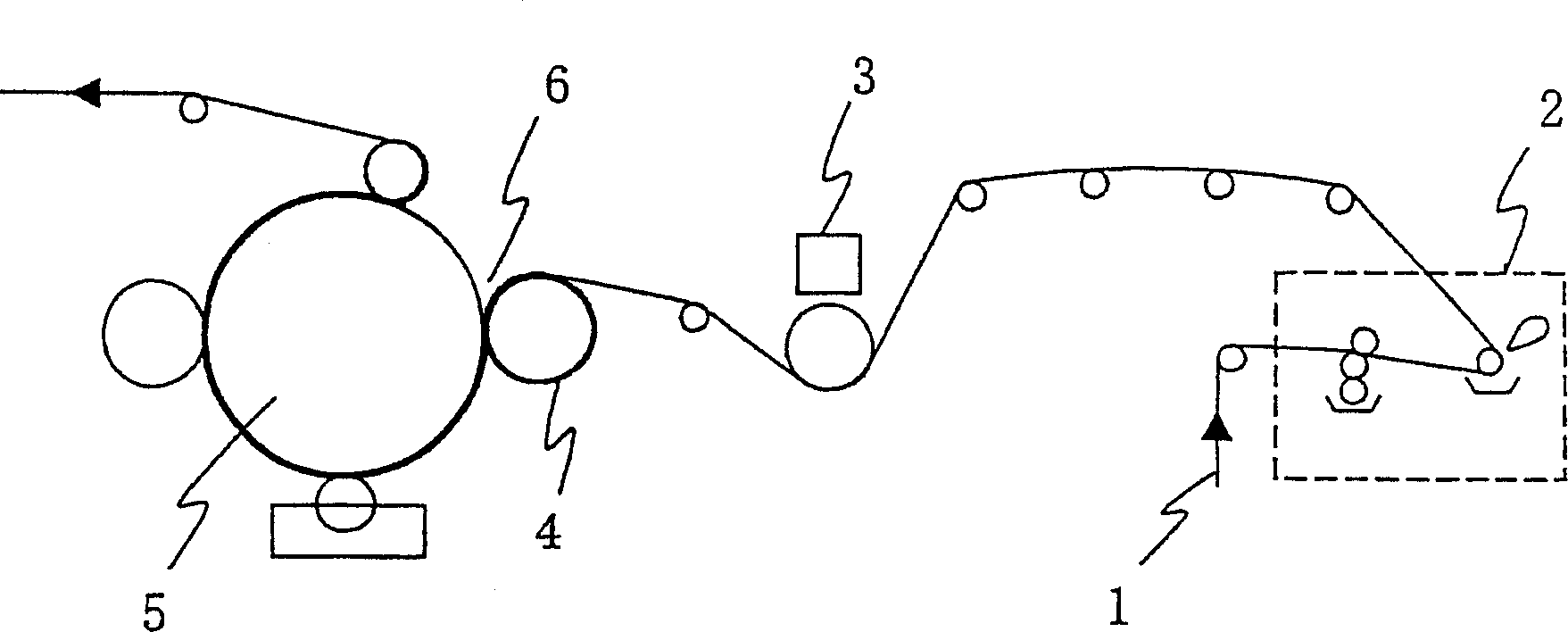

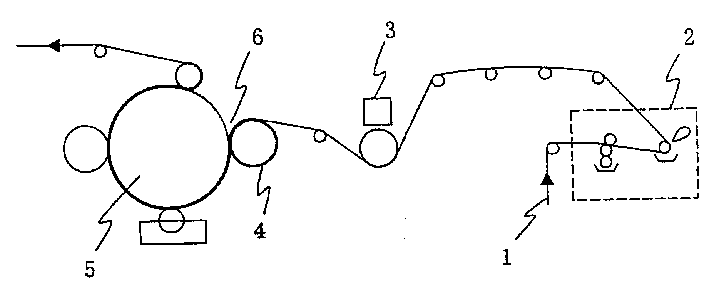

Method used

Image

Examples

Embodiment 1

[0039] The coating liquid A used the following composition. And the polyacrylic acid aqueous solution with a concentration of 7.5% was used as the gelling agent (and the contents of the components are all expressed as weight %).

[0040] Composition of Coating Solution A

[0041] Precipitated silica (particle size 12μm): 12.2%

[0042] Colloidal silica: 61.0%

[0043] Plastic pigments: 6.1%

[0044] SBR latex: 4.9%

[0045] PVA: 3.0%

[0046] poly-Dadmac: 11.0%

[0047] Polyethylene wax: 1.5%

[0048] Gloss enhancer (OBA): 0.3%

[0049] Total: 100%

[0050] The measurement results of the cast paper obtained using this coating liquid A are as follows.

[0051] White gloss (Sheet Gloss): 85%

[0052] Gloss (highest part): 90.4% ISO

[0053] Coating weight: 18.2g / m 2

[0054] Moisture: 5.1%

[0055] In addition, the results of the inkjet test obtained are shown in Table 1.

[0056] Types of Inkjet Tests

Embodiment 2

[0058] The coating liquid B used the following composition. Moreover, the concentration of the gelling agent is 7.5% polyacrylic acid aqueous solution.

[0059] Composition of Coating Solution B

[0060] Colloidal silica: 71.4%

[0061] Plastic pigments: 10.7%

[0062] PVA: 3.6%

[0063] poly-Dadmac: 10.7%

[0064] Polyethylene wax: 3.6%

[0065] Total: 100%

[0066] The measurement results of the cast paper obtained using this coating liquid B are as follows.

[0067] White gloss (Sheet Gloss): 79%

[0068] Brightness (highest part): 86.3% ISO

[0069] Coating weight: 16.0g / m 2

[0070] Moisture: 6.2%

[0071] Table 2 also shows the results of the inkjet tests obtained separately.

[0072] Types of Inkjet Tests

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com