Production method of porous calcium carbonate

A production method and technology of calcium carbonate, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of high density, poor adsorption force, affecting the quality of synthetic products in the range of calcium carbonate use, achieve large specific surface area, reduce plastic density, Strength-enhancing effect

Inactive Publication Date: 2004-07-28

谢作文

View PDF0 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the inherent defects in the performance of this light calcium carbonate, such as high density, poor adsorption force, etc., it greatly affects the scope of use of calcium carbonate and the quality of synthetic products.

And the market needs a density of 1.6-1.9g / cm 3 , a porous amorphous calcium carbonate crystal with a particle size of 1-10 μm, but has not been reported in the literature so far, and there is no such product

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

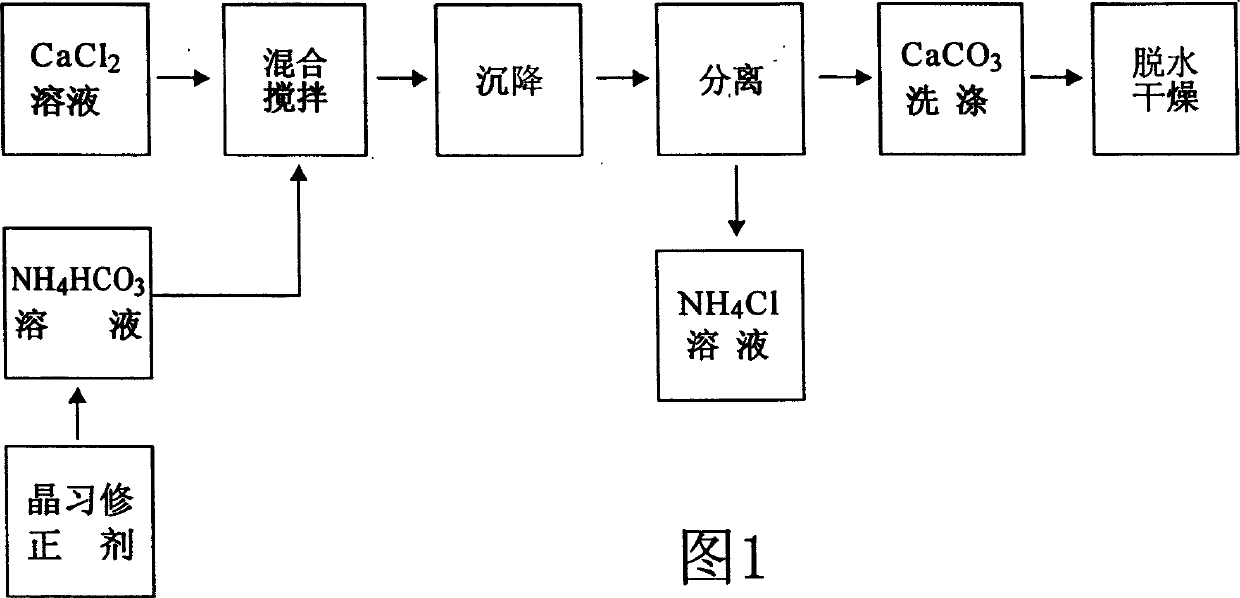

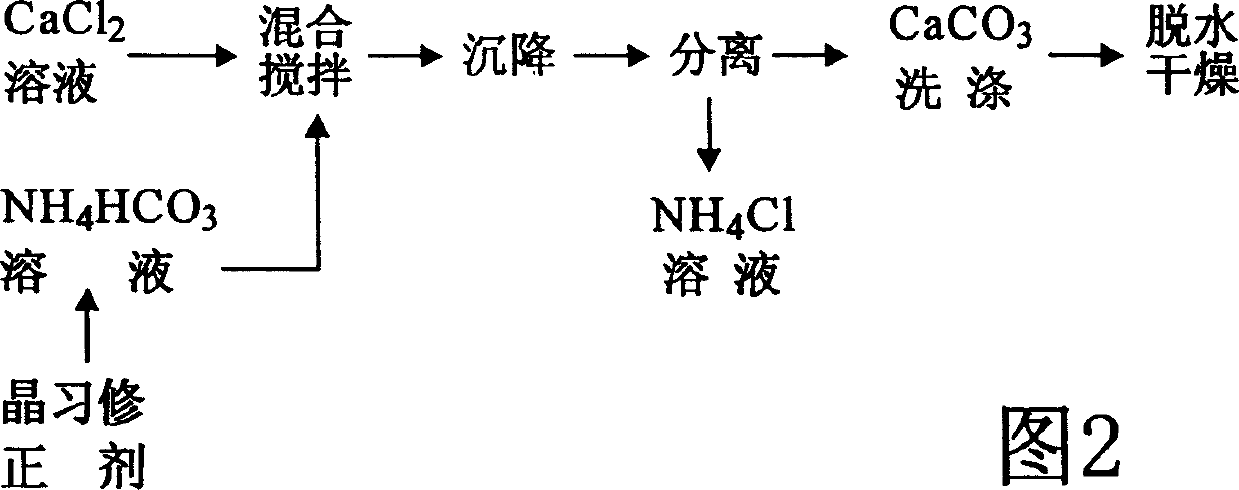

The preparation method of porous calcium carbonate includes the folloiwng steps: preparing calcium chloride aqueous solution and ammonium hydrogen carbonate aqueous solution, adding crystal habit correcting agent whose adding quantity is 0.01-0.05% of total mass of the above-mentioned two solutions; mixing them at 25-30 deg.C, fully stirring at normal pressure until the air is reacted, settling reaction product for 0.5-1 hr., separating sediment calcium carbonate from ammonium hydride solution, then washing said sediment calcium carbonate by using water, dewatering, drying so as to obtain the porous calcium carbonate product with strong adsorption force and penetrating quality. It can be extensively used in the industries of plastics paper-making, paint, printing ink and domestic chemicals, etc.

Description

technical field The present invention relates to the preparation method of compound calcium carbonate, particularly the production method of porous calcium carbonate. Background technique At present, there are more than 300 large and small enterprises producing industrial precipitated light calcium carbonate in my country, mainly producing spindle-shaped light calcium with an average particle size of about 3.5 μm and a density of about 2.4-2.6 g / cm 3 . Due to the inherent defects in this light calcium carbonate performance, such as the deficiencies in aspects such as high density and poor adsorption force, it greatly affects the scope of use of calcium carbonate and the quality of synthetic products. And the market needs a density of 1.6-1.9g / cm 3 , a porous amorphous calcium carbonate crystal with a particle size of 1-10 μm, but there are no reported documents so far, and there is no such product. Contents of the invention The purpose of this invention is to provide ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01F11/18

Inventor 谢作文

Owner 谢作文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com